Rose Integration

Major Late Model & High Precision Multi-Axis CNC Machining Event!

Date

Wednesday, June 5, 2024

Start Time

10:00 AM EDT

Inspection

Tuesday, June 4 from 9 AM to 4 PM or by appointment. Please email info@corpassets.com to arrange.

Removal

All assets must be removed no later than Friday, June 28 by appointment only. Rigging details to follow.

Industry

Corporate Assets Inc. is pleased to announce its recent acquisition of the assets of Rose Integration—a high-precision AS9100D/ISO 9001:2015 compliant and controlled goods facility specializing in the manufacturing of high-tolerant precision components. This sale features a large quantity of Late Model Multi-Axis CNC Machining & Turning Equipment as NEW as 2019! Mark your calendars for this exceptional upcoming event!

MULTI-PALLET 5-AXIS HIGH-SPEED CNC VERTICAL MACHINING CENTERS

- MATSUURA (2019) MX-520 PC4 multi-pallet 5-axis high-speed CNC vertical machining center with MATSUURA G-TECH 31i CNC control, 2.75”-22.83” distance from table surface to spindle gauge line, (4) 11.81” diameter pallets, travels: X-24.80”, Y-22.04”, Z-20.07”, A- -125 to +10 degrees in 0.001 degree increments, C-360 degrees in 0.001 degree increments, spindle speeds to 12,000 RPM, BT40 spindle taper, 90-station ATC, 440 LB maximum workpiece weight, high-pressure coolant, LNS chip conveyor, 200-220V/3PH/60HZ, S/N 21683

- MATSUURA (2010) MAM72-35V multi-pallet 5-axis high-speed CNC vertical machining center with MATSUURA G-TECH 30i CNC control, (32) 5.12” diameter pallets, travels: X-26.77”, Y-15.15”, Z-24.60”, B- +65 to -106 degrees in 0.001 degree increments, C-360 degrees in 0.001 degree increments, BT40 spindle taper, spindle speeds to 20,000 RPM, RENISHAW OMI-2 probe system, MOSNIC chip conveyor, 240-station ATC, CHIP BLASTER JV10 high-pressure high-volume coolant delivery system, 200-220V/3PH/50-60HZ, S/N 18243

MULTI-AXIS OPPOSED SPINDLE AND TWIN TURRET CNC MULTI-TASKING CENTERS

- NAKAMURA-TOME (2018) WT-300 multi-axis opposed spindle and twin turret CNC multi-tasking center with FANUC SERIES 18i-TB CNC control, 10.63” maximum turning diameter, 30.71” maximum turning length, 2.8” maximum bar size main spindle, 2.56” maximum bar size sub spindle, 9.84”-43.31” distance between spindle noses, travels: X1/X2-185”/195”, Z1/Z2-30.71”, Y-+/-2.36”, B2-33.46” in 0.001 degree increments, (2) 24-station turrets, 3.35” main spindle bore, 3.15” sub spindle bore, main spindle speeds to 4,000 RPM, sub spindle speeds to 4,500 RPM, high-pressure coolant, AEROEX ROX 400 ½ HP mist eliminator, tool-measuring probe, LNS chip conveyor, 200-220V/3PH/50-60HZ, S/N M305307

- NAKAMURA-TOME WT-300 multi-axis opposed spindle and twin turret CNC multi-tasking center with FANUC SERIES 18i-TB CNC control, 10.63” maximum turning diameter, 30.71” maximum turning length, 2.8” maximum bar size main spindle, 2.56” maximum bar size sub spindle, 9.84”-43.31” distance between spindle noses, travels: X1/X2-185”/195”, Z1/Z2-30.71”, Y-+/-2.36”, B2-33.46” in 0.001 degree increments, (2) 24-station turrets, 3.35” main spindle bore, 3.15” sub spindle bore, main spindle speeds to 4,000 RPM, sub spindle speeds to 4,500 RPM, high-pressure coolant, AEROEX ROX 400 ½ HP mist eliminator, tool-measuring probe, chip conveyor, 200-220V/3PH/50-60HZ, S/N M301705

- NAKAMURA-TOME WT-300 multi-axis opposed spindle and twin turret CNC multi-tasking center with FANUC SERIES 18i-TB CNC control, 10.63” maximum turning diameter, 30.71” maximum turning length, 2.8” maximum bar size main spindle, 2.56” maximum bar size sub spindle, 9.84”-43.31” distance between spindle noses, travels: X1/X2-185”/195”, Z1/Z2-30.71”, Y-+/-2.36”, B2-33.46” in 0.001 degree increments, (2) 24-station turrets, 3.35” main spindle bore, 3.15” sub spindle bore, main spindle speeds to 4,000 RPM, sub spindle speeds to 4,500 RPM, high-pressure coolant, AEROEX ROX 400 ½ HP mist eliminator, tool-measuring probe, LNS Q.L. SERVO S3 bar feeder, chip conveyor, 200-220V/3PH/50-60HZ, S/N M301707

- NAKAMURA-TOME WT-250 II multi-axis opposed spindle and twin turret CNC multi-tasking center with NAKAMURA-TOME CNC control, 9.84” maximum turning diameter, 21.85” maximum turning length, 8” main spindle chuck, 6” sub spindle chuck, travels: X1/X2-7.68”, Z1/Z2-23.62”, (2) 12-station turrets with live milling, spindles speed to 4,500 RPM, coolant, chip conveyor, HAKUSAN chip conveyor, KUKA (2019) KR 8 R1620 6-AXIS pick & place robot arm with CYBERDRAWERS 4-drawer parts loading system, LNS Q.L. SERVO S3 bar feeder, 200-220V/3PH/50-60HZ, S/N M245401 (T2)

- NAKAMURA-TOME WT-250 multi-axis opposed spindle and twin turret CNC multi-tasking center with FANUC SERIES 18i-TB CNC control, 9.84” maximum turning diameter, 21.85” maximum turning length, 8” main spindle chuck, 6” sub spindle chuck, travels: X1/X2-7.68”, Z1/Z2-23.62”, (2) 12-station turrets with live milling, spindles speed to 4,500 RPM, coolant, chip conveyor, AEROEX ROX-400 ¾ HP mist eliminator, 200-220V/3PH/50-60HZ, S/N M241404

- NAKAMURA-TOME WT-250 multi-axis opposed spindle and twin turret CNC multi-tasking center with FANUC SERIES 18i-TB CNC control, 9.84” maximum turning diameter, 21.85” maximum turning length, 8” main spindle chuck, 6” sub spindle chuck, travels: X1/X2-7.68”, Z1/Z2-23.62”, (2) 12-station turrets with live milling, spindles speed to 4,500 RPM, coolant, chip conveyor, AIRFLOW SYSTEMS MISTPAK mist eliminator, 200-220V/3PH/50-60HZ, S/N M237705

- NAKAMURA-TOME WT-150 multi-axis opposed spindle and twin turret CNC multi-tasking center with FANUC SERIES 18i-TB CNC control, 7.48” swing over bed, 7.48” maximum turning diameter, 15.74” maximum turning length, travels: X1-6.2”, X2-6.59”, Z1/Z2-18.30, Y-+/-1.38”, C-360 degrees in 0.001 degree increments, 6” chuck, speeds to 5,000 RPM, 2.48” spindle bore, (2) 24-station turrets, coolant, FILTERMIST mist eliminator, LNS Q.L. SERVO S3 bar feeder, 200-220V/3PH/50-60HZ, S/N M153504

- NAKAMURA-TOME WT-150 multi-axis opposed spindle and twin turret CNC multi-tasking center with FANUC SERIES 18i-TB CNC control, 7.48” swing over bed, 7.48” maximum turning diameter, 15.74” maximum turning length, travels: X1-6.2”, X2-6.59”, Z1/Z2-18.30, Y-+/-1.38”, C-360 degrees in 0.001 degree increments, 6” chuck, speeds to 5,000 RPM, 2.48” spindle bore, (2) 24-station turrets, coolant, AEROEX PEX 500 ½ HP mist eliminator, LNS Q.L. SERVO S3 bar feeder, 200-220V/3PH/50-60HZ, S/N M155708

- NAKAMURA-TOME WT-100 multi-axis opposed spindle and twin turret CNC multi-tasking center with FANUC SERIES 31i-MODEL A CNC control, 7.48” maximum turning diameter, 19.80” maximum turning length, travels: X1/X2-5.31”, Z1/Z2-19.80”, Y-+/-1.22”, B2-20.67”, C-360 degrees in 0.001 degree increments, 6.5” chuck size, spindle speeds to 6,000 RPM, 2.20” spindle bore, 8.27”-28.94” distance between spindle noses, (2) 24-station turrets, high-pressure coolant, AEROEX mist eliminator, 200-220V/3PH/50-60HZ, S/N M101407

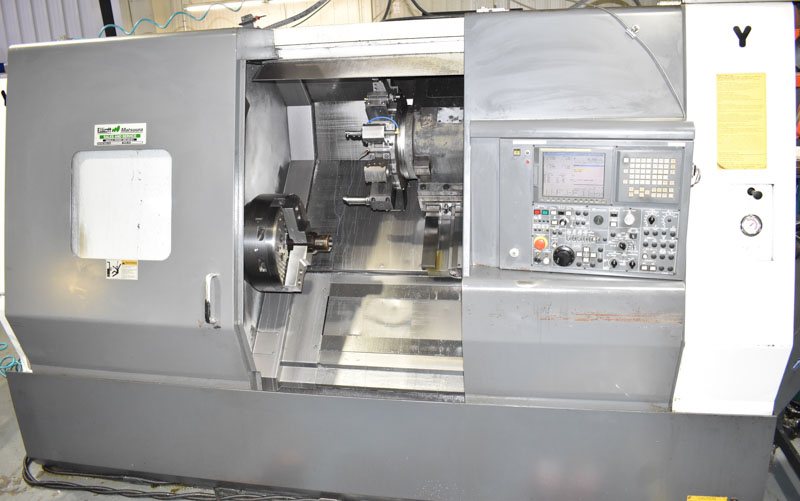

CNC TURNING CENTERS

- HURCO TM6i CNC turning center with HURCO CNC CONTROL, 12-station turret with (6) live milling stations, 12 HP drive motor, 230V/3PH/60HZ, S/N ST6-16006C7EKAAH (L2)

- NAKAMURA-TOME SC-450 CNC turning center with FANUC SERIES 21i-TB CNC control, 31.88” swing over bed, 40.74” distance between centers, 18.30 maximum turning diameter, 28.14” maximum turning length, travels: X-12.4”, Z-32.48”, C-360 degrees in 0.001 degree increments, 18.5” 3-jaw chuck, spindle speeds to 2,500 RPM, 3,93” spindle bore, 12-station turret, hydraulic tailstock, high-pressure coolant, HAKUSAN chip conveyor, AIRFLOW SYSTEMS MISTPAK mist extractor, 200-220V/3PH/50-60HZ, S/N S453903

- NAKAMURA-TOME SC-300 II CNC turning center with FANUC SERIES 21i-TB CNC control, 22.04” swing over bed, 13.77” maximum turning diameter, 23.62” maximum turning length, 28.09 distance between centers, travels: X-8.75”, Z-25”, Y-+/-1.77”, B-19.69”, 10” 3-jaw chuck, spindle speeds to 3,500 RPM, 3.34” main spindle bore, hydraulic tailstock, 12-station turret, 3” spindle bore, HAKUSAN chip conveyor, AEROEX mist eliminator, 200-220V/3PH/50-60HZ, S/N S309005

- NAKAMURA-TOME SC-250 CNC turning center with FANUC SERIES 18i-T CNC control, 9” 3-jaw chuck, 12-station turret, spindle speeds to 5,000 RPM, 2.5” spindle bore, chip conveyor, S/N S201708

- NAKAMURA-TOME SC-150 opposed-spindle CNC turning center with FANUC SERIES 18i-T CNC control, (2) 12-station turrets, parts catcher, AIRFLOW SYSTEMS MISTPAK mist eliminator, chip conveyor, S/N S150605

MULTI-PALLET HIGH-SPEED CNC HORIZONTAL MACHINING CENTER

- MATSUURA (2006) H.PLUS-405 4-axis multi-pallet high-speed CNC horizontal machining center with MATSUURA G-TECH 30i CNC control, (6) 19.68” X 19.68” pallets, travels: X-23.62”, Y-23.62”, Z-23.62”, B-360 degrees in 1 degree increments, 3.14”-26.77” pallet top surface to spindle center line, 25.59” x 29.52” maximum workpiece size, BT40 spindle taper, spindle speeds to 12,000 RPM, 150-STATION ATC, high-pressure coolant, TURBO SYSTEMS chip conveyor, 200-220V/3PH/50-60HZ, S/N 16490 (F1)

TWIN-PALLET HIGH-SPEED CNC HORIZONTAL MACHINING CENTERS

- MATSUURA (2000) ES 450 H2 twin-pallet high-speed CNC horizontal machining center with FANUC SERIES 18i-M CNC control, (2) 11.81” X 11.81” pallets, travels: X-17.72”, Y-15.75”, Z-15.75”, 3.15”-18.9” distance tabletop to spindle nose, 30-station ATC, CAT40 spindle taper, spindle speeds to 15,000 RPM, TURBO conveyor chip conveyor, 200-220V/3PH/50-60HZ, S/N 000614116 (E10)

- MATSUURA (2000) ES 450 H2 twin-pallet high-speed CNC horizontal machining center with FANUC SERIES 18i-M CNC control, (2) 11.81” X 11.81” pallets, travels: X-17.72”, Y-15.75”, Z-15.75”, 3.15”-18.9” distance tabletop to spindle nose, 30-station ATC, CAT40 spindle taper, spindle speeds to 15,000 RPM, TURBO CONVEYOR chip conveyor, high-pressure coolant, 200-220V/3PH/50-60HZ, S/N 000514031 (E6)

- MATSUURA (2000) ES 450 H2 twin-pallet high-speed CNC horizontal machining center with FANUC SERIES 18i-M CNC control, (2) 11.81” X 11.81” pallets, travels: X-17.72”, Y-15.75”, Z-15.75”, 3.15”-18.9” distance tabletop to spindle nose, 30-station ATC, CAT40 spindle taper, spindle speeds to 15,000 RPM, TURBO CONVEYOR chip conveyor, high-pressure coolant, 200-220V/3PH/50-60HZ, S/N 000614106 (E3)

- MATSUURA (2000) ES 450 H2 twin-pallet high-speed CNC horizontal machining center with FANUC SERIES 18i-M CNC control, (2) 11.81” X 11.81” pallets, travels: X-17.72”, Y-15.75”, Z-15.75”, 3.15”-18.9” distance tabletop to spindle nose, 30-station ATC, CAT40 spindle taper, spindle speeds to 15,000 RPM, TURBO CONVEYOR chip conveyor, high-pressure coolant, 200-220V/3PH/50-60HZ, S/N 000714177 (E9)

- MATSUURA (2000) ES 450 H2 twin-pallet high-speed CNC horizontal machining center with FANUC SERIES 18i-M CNC control, (2) 11.81” X 11.81” pallets, travels: X-17.72”, Y-15.75”, Z-15.75”, 3.15”-18.9” distance tabletop to spindle nose, 30-station ATC, CAT40 spindle taper, spindle speeds to 15,000 RPM, TURBO CONVEYOR chip conveyor, CHIP BLASTER JV10 high-pressure high-volume coolant delivery system, 200-220V/3PH/50-60HZ, S/N 000814222

HIGH-SPEED CNC VERTICAL MACHINING CENTER

- MATSUURA (2000) MC-800VG2 high-speed CNC vertical machining center with YASNAC CNC control, 20.07” x 45.27” table, travels: X-31.5”, Y-20.07”, Z-19.68”, 5.9”-25.59” distance between tabletop to spindle nose, spindle speeds to 20,000 RPM (to be verified), BT40 spindle taper, 30-station ATC, high-pressure coolant, TURBO CONVEYOR chip conveyor, 200-220V/3PH/50-60HZ, S/N 000113869

TWIN-PALLET HIGH-SPEED CNC VERTICAL MACHINING CENTERS

- MATSUURA (2000) RA-4G twin-pallet high-speed CNC vertical machining center with YASNAC CNC control, (2) 19.29” x 39.37” pallets, travels: X-40.15”, Y-21.65”, Z-20.08”, 5.9”-25.98” distance between tabletop surface to spindle nose, spindle speeds to 15,000 RPM, BT40 spindle taper, 30-station ATC, 1,102 LB maximum workpiece weight, high-pressure coolant, TURBO CONVEYOR chip conveyor, 200-220V/3PH/60HZ, S/N 000314085

- MATSUURA (2000) RA-4G twin-pallet high-speed CNC vertical machining center with YASNAC CNC control, (2) 19.29” x 39.37” pallets, travels: X-40.15”, Y-21.65”, Z-20.08”, 5.9”-25.98” distance between tabletop surface to spindle nose, spindle speeds to 15,000 RPM, BT40 spindle taper, 30-station ATC, 1,102 LB maximum workpiece weight, high-pressure coolant, TURBO CONVEYOR chip conveyor, 200-220V/3PH/60HZ, S/N 000614289

- MATSUURA (2000) RA-3G2 twin-pallet high-speed CNC vertical machining center with YASNAC CNC control, (2) 19.3” x 31.5” pallets, travels: X-31.5”, Y-20.07”, Z-19.68”, 5.9”-25.59” distance between tabletop to spindle nose, CAT40 spindle taper, spindle speeds to 12,000 RPM, 660 LB maximum pallet load capacity, 30-station ATC, high-pressure coolant, TURBO CONVEYOR chip conveyor, 200-220V/3PH/50-60HZ, S/N 000313972

- MATSUURA (2000) RA-3G2 twin-pallet high-speed CNC vertical machining center with YASNAC CNC control, (2) 19.3” x 31.5” pallets, travels: X-31.5”, Y-20.07”, Z-19.68”, 5.9”-25.59” distance between tabletop to spindle nose, CAT40 spindle taper, spindle speeds to 12,000 RPM, 660 LB maximum pallet load capacity, 30-station ATC, high-pressure coolant, TURBO CONVEYOR chip conveyor, 200-220V/3PH/50-60HZ, S/N 000313971

- MATSUURA (2000) RA-2G twin-pallet high-speed CNC vertical machining center with YASNAC CNC control, (2) 17.3” x 28.3” pallets, travels: X-26”, Y-18.11”, Z-19.09”, 5.9”-25” distance between tabletop to spindle nose, 550 LB maximum workpiece weight, spindle speeds to 15,000 RPM, BT40 spindle taper, 30-station ATC, TURBO CONVEYOR chip conveyor, high-pressure coolant, 200-220V/3PH/50-60HZ, S/N 000313959 (G3)

CNC LATHE

- BRIDGEPORT EZ-PATH SD CNC lathe with 40” distance between centers, 17” swing over bed, 8” swing over cross slide, travels: X-8.66”, Z-40”, spindle speeds to 4,000 RPM, 240V/3PH/60HZ, S/N 002-083978-363

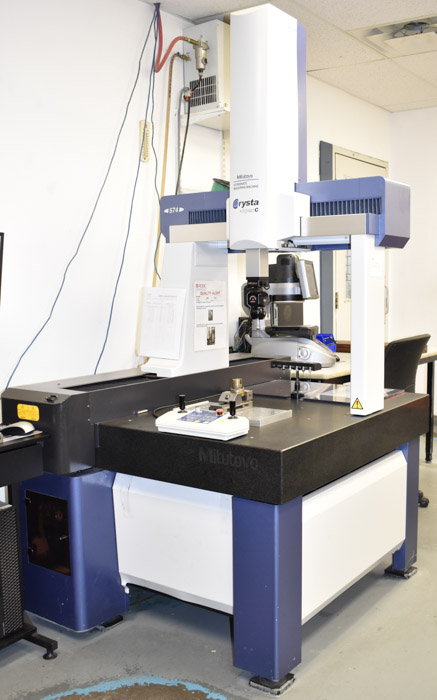

INSPECTION EQUIPMENT

- MITUTOYO CMMC-J CSA/D CRYSTA-APEXC coordinate measuring machine with 46” x 28.25” granite surface plate, RENISHAW PH10T touch probe, RENISHAW PI4-2 probe interface, RENISHAW PHC 10-2 probe head controller, RENISHAW HCU1 hand controller, GEOPAK CMM MCOSMOS-2 V4.3.3 software, S/N 600065

- MITUTOYO BRT-A707 BRIGHT APEX coordinate measuring machine with 52” x 38.5” granite surface plate, RENISHAW PH10T touch probe, RENISHAW PHC10-2 probe head controller, RENISHAW HCU1 hand controller, GEOPAK CMM MCOSMOS-2 V4.3 software, S/N 1498004C

- ZEISS SURFCOM 1900SD2 contour measuring instrument detector, S/N K3970222

- KEYENCE IM-6225 IM SERIES digital image dimension measuring system, S/N #7C518156

- MITUTOYO PH-3500 SHADOWGRAPH profile projector with MITUTOYO MICROPAK 2 2-AXIS DRO, S/N 800232

- NEWAGE ME-2RDS ROCKWELL hardness testing system with AMETEK control, 115V/1PH/50-60HZ, S/N 4539

- MEIJI EMZ stereo microscope, S/N 73670

- MITUTOYO 521-108 calibration tester, S/N 083445

- TESA HITE 700 digital height gauge, S/N 5C 0378 02

- MITUTOYO 18” digital height gauge, S/N N/A

- MITUTOYO 12” digital height gauge, S/N N/A

- MFG UNKNOWN 36” X 48” X 8.5” granite surface plate with stand, S/N N/A

- MITUTOYO 24” X 24” X 4” granite surface plate, S/N 4559

- MFG UNKNOWN 24” X 36” X 6” granite surface plate with rolling stand, S/N N/A

- MFG UNKNOWN 18” X 18” X 4” granite surface plate, S/N N/A

- DOALL 18” X 18” X 3.25” granite surface plate, S/N 1052-2

- STARRETT 12” X 18” X 4” granite surface plate, S/N N/A

- (2) MFG UNKNOWN 12” X 18” X 3.5” granite surface plates, S/N N/A

MATERIAL HANDLING EQUIPMENT

- TOYOTA 7FGU25 LPG forklift with 3,750 LB maximum capacity, 189” maximum vertical reach, back-tilt, side-shift, 10,173 hours (recorded on meter at time of listing), S/N 78585

- EKKO EB13E-138 24V electric pallet stacker with 2,800 LB lifting capacity, 138” maximum lift height, built-in charger, S/N EK1906E0012/190628447

- LIFT-RITE LCR55 hydraulic pallet jack with 5,500 LB capacity, S/N 5037868-11

- LIFT-RITE L50 hydraulic pallet jack with 5,500 LB capacity, S/N G 06582-00

- MAHAFFY MATERIALS HANDLING PALLET WRANGLER 90 hydraulic pallet jack with 5,500 LB capacity, S/N 97350

- (4) GORBEL freestanding jib crane with 250 LB capacity, CM SHOPSTAR electric hoist, 112” arm, 112” height under hook, 220-230V/3PH/50-60HZ, S/N 592849

- GORBEL freestanding jib crane with 150 LB capacity, PULLZALL 1,000 LB capacity electric winch, 112” arm, 112” height under beam, S/N 317232

CONVENTIONAL MACHINERY

- LILIAN (2000) 5VII CNC milling machine with 10” x 50” table, speeds to 4,200 RPM, ACU-RITE 3-AXIS CNC control, S/N 10173

- CLAUSING CSG-1020ASD hydraulic surface grinder with 10” x 20” magnetic chuck, 840 LB maximum table load, coolant with paper filtration, 575V/3PH/60HZ, S/N 257019

- CYCLEMATIC CHR-68 precision turret lathe with speeds to 3,000 RPM, coolant, 8-station turret, 575V/3PH/60HZ, S/N 8805023

- HYD-MECH S-20A horizontal bandsaw with 3 & 2 HP motors, 600V/3PH/60HZ, S/N 80400865

- BOMAR (2008) TRANSVERSE 510.330 GA horizontal bandsaw with 92” x 71” x 70” cutting capacity, 3,300 LB maximum workpiece weight, 3X400V/3PH/60HZ, S/N F180

- MEP COBRA 350AX automatic abrasive cut off saw, S/N 01953111

- VERTICUT 114-A vertical bandsaw with 18.5” x 30.25” table, ¾ HP motor, 115V/1PH/60HZ, S/N 1556

- MASTERCRAFT vertical band saw with 11-3/4” x 11-3/4” table, blade speeds to 2,556 SFM, 9” maximum cutting width, 3-1/8” maximum cutting depth, 120V/1PH/60HZ, S/N N/A

- KING CANADA (2017) KC-129C 5” X 6” horizontal metal cutting bandsaw with speeds to 1,720 RPM, 115V/1PH/60HZ, S/N 71C00187

- KING CANADA KC-706L 6” belt & 9” disc sander with belt speeds to 2,100 SFM, disc speeds to 2,700 RPM, 110V/1PH/60HZ, S/N 039029

- DEWALT DW756 6” double end bench grinder, 120V/1PH/60HZ, S/N 2022 44 YL66268J

- CHING YIH TOOLS MFG PREGRAPH U2 tool & cutter grinder, 115V/1PH/60HZ, S/N 0755

- RUSH MACHINERY (2006) 132C tool & cutter grinder with ½ HP motor, 115V/1PH/60HZ, S/N 2655

- MFG UNKNOWN arbor press with 8” throat, S/N N/A

- LIANG YU TOOL arbor press with 8” throat, S/N N/A

- MFG UNKNOWN 20 TON hydraulic shop press, S/N N/A

- KING CANADA (2021) KHP-10T-GGN 10 TON benchtop hydraulic shop press, S/N 18826-048

- POWERFIST 10 TON benchtop hydraulic shop press with 6-7/8” stroke, 4-21/64” to 14-5/16” working range, S/N N/A

- GENERAL PNEUMATIC TOOLS 6000 CS pneumatic bench-mounted riveter, S/N 7948

- GENERAL 340 drill press with 10” x 11” table, ¾ HP motor, 115V/1PH/60HZ, S/N G8230

- GENERAL 340 benchtop drill press with 10” x 11” table, ¾ HP motor, 115V/1PH/60HZ, S/N G10289

FACTORY SUPPORT EQUIPMENT

- AUTOCRIB ROBOCRIB VX1000 digital tool vending system with AUTOCRIB SCALEMATE inventory control, S/N N/A

- ROTO FINISH ER-5BS vibratory finishing machine with 48” diameter chamber, 3 HP motor, 10,807 hours (recorded on meter at time of listing), S/N 5BS-85-A21

- SULLAIR (2021) SN5509S 75 AC 93 HP air compressor with 125-135 PSI operating pressure, 1,780 RPM, 575V/3PH/60HZ, S/N 202104190036

- SULLAIR SRB375 refrigerated air dryer with 375 SCFM nominal flow rate, 203 PSI maximum air pressure, S/N 200025785/20

- KAESER SIGMA AS 31 air compressor, S/N N/A

- XEBEC RAD250 ADXCOOL refrigerated air dryer with 232 PSIG design pressure, 230V/1PH/50-60HZ, S/N 1820MA11987

- INGERSOLL-RAND SSR-EP25 25 HP air compressor with 97 CFM capacity, 125 PSIG rated operating pressure, 575V/3PH/60HZ, S/N JX1367U00080

- OMEGA TK 5080V-05 5 HP air compressor with 150 PSI capacity, 575V/3PH/60HZ, S/N PLP-04031178

- KENNAMETAL ISG2200-WK-USA THERMOGRIP induction unit with 85-150 PSI pressure, 400V/3PH/50-60HZ, S/N 2515 37/11

- LASER MARKING TECHNOLOGIES (2017) COBALT-DOM-20PF DOMINATOR laser parts marker, 110V/1PH/50-60HZ, S/N 9493

- GRAVOTECH (2023) IMPACT EZ M DOT PEEN marking station with GRAVOTECH rotary device, 100-240V/1PH/50-60HZ, S/N SN000034856

- PRYOR (2010) DOT PEEN marking station with WALKER CERAMAX 18” X 6” magnetic chuck, PRYOR control, S/N 27298801

- DIVERSITECH MDD-3X8 80-gallon wet downdraft table with 98” x 41” x 36” work surface, 6,500 CFM nominal airflow, 15 HP motor, 575V/3PH/60HZ, S/N 45627

- BRANSON ULTRASONICS FLEXLINE parts cleaning system, S/N N/A

- POWERFIST floor model sandblasting cabinet, S/N N/A

- WILLIAMS & WILSON GHTF-RT heat treat furnace, 240V/3PH/60HZ, S/N Y 1997-GA20549

- AMERICAN SCREEN PRINTING EQUIPMENT PHOTOSONIC washer-viewer, S/N 483968

- NUARC COMPANY 40-1K-7LJ mercury exposure system with 42.5” x 33” work area, 100-120V/1PH/60HZ, S/N 7LJ-B90-003

- MFG UNKNOWN approx. 24’ x 16’ x 13’H all-bolted construction mezzanine structure, S/N N/A

ALSO:

- High precision perishable tooling; live milling holders and machinery support tooling; quality control and inspection equipment; LISTA type cabinets, cantilever material storage racking, rolling tool storage carts; flammable storage cabinets; SUNEX 5001A 6” double end bench grinders; shop tables; hand tools; office furniture; business machines & MUCH MORE!