JD Norman Canada, ULC

Complete Tier 1 Automotive (Specialty Formed) Cast & Machined Parts Manufacturing Facility

Date

Wednesday, June 9, 2021

Start Time

9:30 AM EDT

Inspection

BY APPOINTMENT ONLY. Please email info@corpassets.com to arrange a date and time.

Removal

All assets must be removed no later than Wednesday, June 30 BY APPOINTMENT ONLY. Please email info@corpassets.com to arrange.

Industry

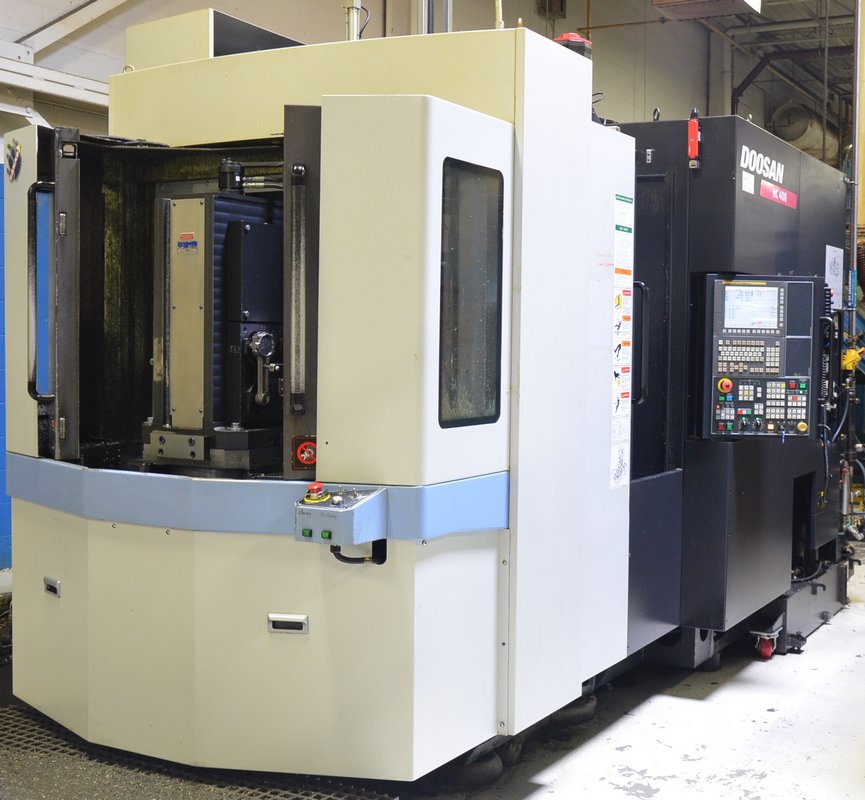

CNC HORIZONTAL MACHINING CENTER

- DOOSAN (2014) HC400 4-axis twin pallet CNC horizontal machining center with SERIES 32i-MODEL B CNC control, 15.75” x 15.75” drilled & tapped pallets, travels X-23.62”, Y-22.05”, Z-22.24”, B-360 degrees, 24.02” max distance spindle nose to table top, 880 lbs max table load capacity, speeds to 10,000 rpm, CAT40 spindle taper, 60 station ATC, high pressure through spindle coolant, flood coolant, chip augers and conveyor, tool probe system, optional hydraulic clamping tombstones, 200-220v/3ph/50-60hz, s/n MH0001-000812

CNC HIGH VOLUME 5-AXIS PRECISION MACHINING CENTER

- CHIRON (2004) DZ 15K W MAGNUM high speed twin pallet, twin spindle, 5-axis CNC machining center with FANUC SERIES 180i-MB CNC control, rotary type pallet changer with 31.49” x 20.47” twin swivel tables, 440 lbs max table capacity, travels X-24.80”, Y-15.74”, Z-14.17”, twin spindles with speeds to 12,000 rpm, (2) 20 hp spindle drives, HSK-A63 spindle taper, (24) station ATC, coolant, chip conveyor, BLUM laser tool measurement system, 400v/3ph/60hz, s/n 188-09

CNC DOUBLE DISK GRINDERS

- C&B MACHINERY (2016) SDG6-42 RECIPROCATOR CNC horizontal double disk finishing grinder with SIEMENS SINUMERIK CNC control, 50 hp opposing spindles with 42” diameter wheels, speeds to 550 rpm, auto wheel dresser, programmable auto compensation, reciprocating feeder, safety light curtains, coolant, 480v/3ph/60hz, s/n 15185

- C&B MACHINERY (remanufactured 2012) SDG6-42 CNC horizontal double disk finishing grinder with SIEMENS SINUMERIK CNC control, 50 hp opposing spindles with 42” diameter wheels, speeds to 550 rpm, auto wheel dresser, programmable auto compensation, auto feeder, safety light curtains, coolant, 480v/3ph/60hz, s/n 11183

- LANDIS GARDNER SDG6-42 OP60 CNC horizontal double disk finishing grinder with GARDNER LECTRIFEED IV CNC control, 50 hp opposing spindles with 42” diameter wheels, speeds to 550 rpm, auto wheel dresser, programmable auto compensation, auto rotary feeder, safety light curtains, coolant, MARPOSS inline auto gauge system, 480v/3ph/60hz, s/n DD-89888

- LANDIS GARDNER SDG6-42 OP60 CNC horizontal double disk finishing grinder with GARDNER LECTRIFEED IV CNC control, 50 hp opposing spindles with 42” diameter wheels, speeds to 550 rpm, auto wheel dresser, programmable auto compensation, auto rotary feeder, safety light curtains, coolant, MARPOSS inline auto gauge system, 480v/3ph/60hz, s/n DD-89886

AUTOMOTIVE FLEXIBLE MANUFACTURING LINES

TRI-WAY (2016) LVL automotive flexible manufacturing line currently configured for GM L86/LT1 connecting rods consisting of:

- TRI-WAY (2016) OP10 4-axis CNC twin station horizontal machining center with ALLEN BRADLEY 1500P touch screen CNC control, (8) spindle roughing, milling and drilling station, (10) spindle drilling, boring, broaching & tapping station, dual trunnion rotary indexing tables, coolant, chip conveyor, 480v/3ph/60hz, s/n TW1723

- TRI-WAY (2016) OP20 connecting rod hydraulic fracturing and assembly machine with ALLEN BRADLEY touch screen PLC control, DEANE SYSTEMS hardware feeder, FEC (2001) AFC1500 connecting rod bolt run-down system with digital torque monitoring and control, REXROTH hydraulics, safety light curtains, 480v/3ph/60hz, s/n 10128

- TRI-WAY (2016) OP30 servo driven vertical hardware insertion press with ALLEN BRADLEY DSP SYSTEM touch screen PLC control, safety light curtains, 480v/3ph/60hz, s/n TW1724

- C&B MACHINERY (2016) SDG6-42 RECIPROCATOR CNC horizontal double disk finishing grinder with SIEMENS SINUMERIK CNC control, 50 hp opposing spindles with 42” diameter wheels, speeds to 550 rpm, auto wheel dresser, programmable auto compensation, reciprocating feeder, safety light curtains, coolant, 480v/3ph/60hz, s/n 15185

- TRI-WAY (2016) OP50 4-axis CNC twin station horizontal machining center with ALLEN BRADLEY 1500P touch screen CNC control, (3) spindle milling, drilling and finishing station, (4) spindle drilling, boring and milling station, dual trunnion rotary indexing tables, coolant, chip conveyor, 480v/3ph/60hz, s/n TW1726

- ACCU-CUT (2016) ACCUBORE 2X3SM-1 CNC multi spindle precision vertical honing machine with ALLEN BRADLEY PANEL VIEW PLUS 1000 touch screen CNC control, (2) heads with (4) spindles/head, (10) station rotary transfer table, coolant, bag type filtration, safety light curtains, 460v/3ph/60hz, s/n BSM-0521

- MDI-JD NORMAN (2016) OP70 high volume through type uplift hot parts washer with twin parallel 6” stainless steel belt conveyor, top & bottom nozzles, blow off dry, safety interlocks, 480v/3ph/60hz, s/n MD5854

- VIDEOJET EXCEL 2000 portable inkjet coding machine with flex print head, 100-240v/1ph/60hz, s/n 08171012CWD

- SMOGHOG SHM-11C cartridge type mist extractor with twin 5 hp blowers, 480v/3ph/60hz, s/n 60072803

TRI-WAY (2002) FLEX automotive flexible manufacturing line currently configured for GM 6.2L-LT4 connecting rods consisting of:

- TRI-WAY (2002) (retrofit & retooled 2012) OP20 CNC horizontal machining center with REXROTH INDRAMAT SYSTEM 200 WINDOWS PC based CNC control, (3) spindle roughing, milling and drilling stations, manual loading station with auto rotator, flex steel belt in-feed conveyor, overhead pick and place auto feed system, coolant, filtration, chip conveyor, 480v/3ph/60hz, s/n TW1463

- TRI-WAY (2002) (retrofit & retooled 2012) OP30 CNC boring and broaching horizontal machining center with REXROTH INDRAMAT SYSTEM 200 BTW20 WINDOWS PC based CNC control, boring and broaching stations, flex steel belt in-feed conveyor, overhead pick and place auto feed system, coolant, filtration, chip conveyor, 480v/3ph/60hz, s/n TW1464

- TRI-WAY (2002) (retrofit & retooled 2012) OP40 CNC drilling and facing horizontal machining center with REXROTH INDRAMAT SYSTEM 200 BTW20 WINDOWS PC based CNC control, milling and drilling stations, flex steel belt in-feed conveyor, overhead pick and place auto feed system, coolant, filtration, chip conveyor, 480v/3ph/60hz, s/n TW1465

- TRI-WAY (2002) (retrofit & retooled 2012) OP60 CNC horizontal machining center with REXROTH INDRAMAT SYSTEM 200 BTW20 WINDOWS PC based CNC control, milling, reaming and tapping stations, flex steel belt in-feed conveyor, overhead pick and place auto feed system, coolant, filtration, chip conveyor, 480v/3ph/60hz, s/n TW1466

- TRI-WAY (FEDERAL MOGUL retrofit & retooled 2012) OP70 CNC (8) station rotary transfer machine with PRO FACE touch screen CNC control, loading station, hydraulic fracturing station, hardware insertion station, twin spindle torque station, twin spindle re-torque station, bushing press insertion station, unload station, flex steel belt in-feed and out-feed conveyors, gauge system, 480v/3ph/60hz, s/n n/a

- CHIRON (2004) DZ 15K W MAGNUM high speed twin pallet, twin spindle, 5-axis CNC machining center with FANUC SERIES 180i-MB CNC control, rotary type pallet changer with 31.49” x 20.47” twin swivel tables, 440 lbs max table capacity, travels X-24.80”, Y-15.74”, Z-14.17”, twin spindles with speeds to 12,000 rpm, (2) 20 hp spindle drives, HSK-A63 spindle taper, (24) station ATC, coolant, chip conveyor, BLUM laser tool measurement system, 400v/3ph/60hz, s/n 188-09

- FANUC (2013) M-710iC 6-axis pick and place robot with FANUC SYSTEM R30-iB controller, digital pendant control, 480v/3ph/60hz, s/n E13642405

- FANUC (2005) M-16iB 6-axis pick and place robot with FANUC SYSTEM R-J3-iB controller, digital pendant control, 480v/3ph/60hz, s/n E05502913

- C&B MACHINERY (remanufactured 2012) SDG6-42 CNC horizontal double disk finishing grinder with SIEMENS SINUMERIK CNC control, 50 hp opposing spindles with 42” diameter wheels, speeds to 550 rpm, auto wheel dresser, programmable auto compensation, auto feeder, safety light curtains, coolant, 480v/3ph/60hz, s/n 11183

- TRI-WAY (2002) (retrofit & retooled 2012) OP90 CNC T.P. horizontal machining center with REXROTH INDRAMAT SYSTEM 200 BTW20 WINDOWS PC based CNC control, twin spindle stations, flex steel belt in-feed conveyor, overhead pick and place auto feed system, coolant, filtration, chip conveyor, 480v/3ph/60hz, s/n TW1467

- TRI-WAY (2002) (retrofit & retooled 2012) OP100 CNC boring and milling horizontal machining center with REXROTH INDRAMAT SYSTEM 200 BTW20 WINDOWS PC based CNC control, boring and face milling stations, flex steel belt in-feed conveyor, overhead pick and place auto feed system, coolant, filtration, chip conveyor, 480v/3ph/60hz, s/n TW1468

- TEXTRON MICROMATIC OP110 CNC (6) spindle, vertical, in-line precision honing machine with HMI CNC control, (6) spindle, (3) pass bore finishing operation, continuous linear gauge system, in-feed/out-feed conveyor, coolant, filtration, 480v/3ph/60hz, s/n n/a

- RJ-CYR OP120 high volume through type uplift hot parts washer with twin parallel 6” stainless steel belt conveyor, top & bottom nozzles, blow off dry, safety interlocks, 480v/3ph/60hz, s/n n/a

TRI-WAY FCA-CHRY automotive flexible manufacturing line currently configured for FCA-CHRYSLER TIGERSHARK 2.0L & 2.4L connecting rods consisting of:

- VALIANT OP15 AUTOMATION load, lift and carry system with PLC control, 480v/3ph/60hz, s/n TW1388-15-380

- TRI-WAY OP20 (14) station linear transfer machine with ALLEN BRADLEY PANEL VIEW PLUS 1000 PLC control, horizontal roughing, milling, boring and drilling operations, auto loading station with rotator, flex steel belt in-feed conveyor, overhead pick and place auto feed system, coolant, filtration, chip conveyor, 480v/3ph/60hz, s/n TW1496

- VALIANT OP25 AUTOMATION load, lift and carry system with PLC control, 480v/3ph/60hz, s/n TW1388-25-380

- TRI-WAY OP30 (13) station linear transfer machine with ALLEN BRADLEY PANEL VIEW PLUS 1000 PLC control, horizontal roughing, milling, boring, facing and drilling operations, auto loading station with rotator, flex steel belt in-feed conveyor, overhead pick and place auto feed system, coolant, filtration, chip conveyor, 480v/3ph/60hz, s/n TW1381

- VALIANT OP35 AUTOMATION load, lift and carry system with PLC control, 480v/3ph/60hz, s/n TW1388-35-380

- TRI-WAY OP50 (19) station carousel type rotary transfer machine with ALLEN BRADLEY PANEL VIEW PLUS 1000 PLC control, loading station, hydraulic fracturing station, hardware insertion station, twin spindle torque station, twin spindle re-torque station, bushing press insertion station, unload station, flex steel belt in-feed and out-feed conveyors, gauge system, 480v/3ph/60hz, s/n TW1382

- VALIANT OP55 AUTOMATION load, lift and carry system with PLC control, 480v/3ph/60hz, s/n TW1388-55-380

- LANDIS GARDNER SDG6-42 OP60 CNC horizontal double disk finishing grinder with GARDNER LECTRIFEED IV CNC control, 50 hp opposing spindles with 42” diameter wheels, speeds to 550 rpm, auto wheel dresser, programmable auto compensation, auto rotary feeder, safety light curtains, coolant, MARPOSS inline auto gauge system, 480v/3ph/60hz, s/n DD-89888

- VALIANT OP65 AUTOMATION load, lift and carry system with PLC control, 480v/3ph/60hz, s/n TW1388-65-380

- TRI-WAY OP70 (11) station linear transfer machine with ALLEN BRADLEY PANEL VIEW PLUS 1000 PLC control, horizontal roughing, milling, boring, facing and drilling operations, auto loading station with rotator, flex steel belt in-feed conveyor, overhead pick and place auto feed system, coolant, filtration, chip conveyor, 480v/3ph/60hz, s/n TW1496

- VALIANT OP75 AUTOMATION load, lift and carry system with PLC control, 480v/3ph/60hz, s/n TW1388-75-380

- NAGEL OP80 CNC double spindle, vertical in-line precision honing machine with FACE PLUS CNC control, (2) spindle, (2) pass bore finishing operation, continuous linear gauge system, in-feed/out-feed conveyor, coolant, filtration, 480v/3ph/60hz, s/n n/a

- VALIANT OP85 AUTOMATION load, lift and carry system with PLC control, 480v/3ph/60hz, s/n TW1388-85-380

- HURRICANE OP95 high volume through type uplift hot parts washer with stainless steel belt conveyor, top & bottom nozzles, blow off dry, safety interlocks, 480v/3ph/60hz, s/n n/a

- HINES OP100 semi-automatic finished goods parts weight grading, sorting and packaging station with ALLEN BRADLEY PANEL VIEW 600 PLC control, 480v/3ph/60hz, s/n 100731

- VIDEOJET EXCEL 2000 portable inkjet coding machine with flex print head, 100-240v/1ph/60hz, s/n n/a

- MONROE ENVIRONMENTAL OMCH-120-12 12,000 CFM capacity mist collector and oil precipitator system with duct work, 480v/3ph/60hz, s/n 99-3522-1

TRI-WAY L850 automotive flexible manufacturing line currently configured for GM connecting rods consisting of:

- VALIANT OP15 AUTOMATION load, lift and carry system with PLC control, 480v/3ph/60hz, s/n n/a

- TRI-WAY OP20 linear transfer machine with ALLEN BRADLEY PANEL VIEW PLUS 1000 PLC control, horizontal roughing, milling, boring and drilling operations, auto loading station with rotator, flex steel belt in-feed conveyor, overhead pick and place auto feed system, coolant, filtration, chip conveyor, 480v/3ph/60hz, s/n TW1535

- VALIANT OP25 AUTOMATION load, lift and carry system with PLC control, 480v/3ph/60hz, s/n n/a

- TRI-WAY OP30 linear transfer machine with ALLEN BRADLEY PANEL VIEW PLUS 1000 PLC control, horizontal roughing, milling, boring, facing and drilling operations, auto loading station with rotator, flex steel belt in-feed conveyor, overhead pick and place auto feed system, coolant, filtration, chip conveyor, 480v/3ph/60hz, s/n TW1536

- VALIANT OP35 AUTOMATION load, lift and carry system with PLC control, 480v/3ph/60hz, s/n n/a

- TRI-WAY OP50 (8) station rotary transfer machine with ALLEN BRADLEY PANEL VIEW PLUS 1000 PLC control, loading station, hydraulic fracturing station, hardware insertion station, twin spindle torque station, twin spindle re-torque station, bushing press insertion station, unload station, flex steel belt in-feed and out-feed conveyors, gauge system, 480v/3ph/60hz, s/n 1537

- VALIANT OP55 AUTOMATION load, lift and flat top carry system with PLC control, 480v/3ph/60hz, s/n n/a

- LANDIS GARDNER SDG6-42 OP60 CNC horizontal double disk finishing grinder with GARDNER LECTRIFEED IV CNC control, 50 hp opposing spindles with 42” diameter wheels, speeds to 550 rpm, auto wheel dresser, programmable auto compensation, auto rotary feeder, safety light curtains, coolant, MARPOSS inline auto gauge system, 480v/3ph/60hz, s/n DD-89886

- VALIANT OP65 AUTOMATION load, lift and carry system with PLC control, 480v/3ph/60hz, s/n n/a

- TRI-WAY OP70 linear transfer machine with ALLEN BRADLEY PANEL VIEW PLUS 1000 PLC control, horizontal roughing, milling, boring, facing and drilling operations, auto loading station with rotator, flex steel belt in-feed conveyor, overhead pick and place auto feed system, coolant, filtration, chip conveyor, 480v/3ph/60hz, s/n TW1532

- VALIANT OP75 AUTOMATION load, lift and carry system with PLC control, 480v/3ph/60hz, s/n n/a

- TEXTRON MICROMATIC OP110 CNC (6) spindle, vertical, in-line precision honing machine with HMI CNC control, (6) spindle, (3) pass bore finishing operation, continuous linear gauge system, in-feed/out-feed conveyor, coolant, filtration, 480v/3ph/60hz, s/n n/a

- VALIANT OP75 AUTOMATION load, lift and carry system with PLC control, 480v/3ph/60hz, s/n n/a

- MIDBROOK (2006) 5004-W/I/B0 OP90 high volume through type uplift hot parts washer with stainless steel belt conveyor, top & bottom nozzles, blow off dry, safety interlocks, 480v/3ph/60hz, s/n 44921

- HINES (2006) OP100 semi-automatic finished goods parts weight grading, sorting and packaging station with ALLEN BRADLEY PANEL VIEW 600 PLC control, 480v/3ph/60hz, s/n n/a

- VIDEOJET EXCEL 2000 portable inkjet coding machine with flex print head, 100-240v/1ph/60hz, s/n n/a

- MONROE ENVIRONMENTAL OMC-060-6-12 6,400 CFM capacity mist collector and oil precipitator system with duct work, 480v/3ph/60hz, s/n 98-3326-1

- MONROE ENVIRONMENTAL OMC-060-6-12 6,400 CFM capacity mist collector and oil precipitator system with duct work, 480v/3ph/60hz, s/n 98-3326-2

Q.C. & INSPECTION EQUIPMENT

- ZEISS (2016) DURAMAX 5/5/5 coordinate measuring machine with 19.5” x 19.5” drilled and tapped steel table, measuring range X-20”, Y-20”, Z-20”, VAST XXT scanning probe head, (9) station auto change rack, ZEISS CALYPSO software, selection of stylus, heads and accessories, 100-240v/1ph/50-60hz, s/n 190389

- MITUTOYO MF 176-532A digital measuring microscope with MITUTOYO 2-axis DRO, SONY SSC-DC80 color camera with monitor, s/n 660101

- MITUTOYO 967-202 26” conventional bench center, s/n 610005

MAINTENANCE DEPARTMENT

- LINCOLN ELECTRIC POWERMIG 255 digital portable MIG welder with cables and gun, s/n n/a

- LINCOLN ELECTRIC IDEALARC 250 ARC welder with cables and gun, s/n C1990400535

- LINCOLN ELECTRIC IDEALARC 250 ARC welder with cables and gun, s/n C1990400487

- KING KC-450 vertical metal cutting band saw with 18” throat, 10” max workpiece height, blade welder and grinder, 220v/1ph/60hz, s/n 1646522

- MFG UNKNOWN 10” metal cutting horizontal band saw, s/n n/a

- KBC S-2A vertical turret milling machine with 9”x42” table, speeds to 4,000 rpm, ACU-SCALE 2-axis DRO, 230v/1ph/60hz, s/n 988029

- KENT KGS-250AH hydraulic surface grinder with 8” x 18” magnetic chuck, coolant, incremental down feed, 575v/3ph/60hz, s/n 86010407

- GRIP 1345 tool room lathe with 13” swing, 45” distance between centers, 4” 3-jaw chuck, s/n 9841064

FACTORY SUPPORT EQUIPMENT

- ATLAS COPCO (2013) GA90VSD 125 hp rotary screw type air compressor with digital microprocessor control, 619 cfm @ 189 psi MAWP, 575v/3ph/60hz, s/n API661627

- ATLAS COPCO GA55 73 hp rotary screw type air compressor with digital microprocessor control, 254 cfm @ 183 psi MAWP, 575v/3ph/60hz, s/n AII465303

- ATLAS COPCO GA37 50 hp rotary screw type air compressor with digital microprocessor control, 220 cfm @ 132 psi MAWP, 575v/3ph/60hz, s/n AII372497

- ATLAS COPCO GA37 50 hp rotary screw type air compressor with digital microprocessor control, 220 cfm @ 132 psi MAWP, 575v/3ph/60hz, s/n AII313762

- FRIULAIR (2015) ACT800-UQ refrigerated air dryer, 575v/3ph/60hz, s/n 150005130

- SULLAIR RD850 refrigerated air dryer, 575v/3ph/60hz, s/n 2812SA01633

ROLLING STOCK

- YALE GLC080LGNGAE085 7,400 lbs capacity LPG forklift with 185” max vertical reach, 3-stage mast, side shift, cushion tires, s/n 8818N01919X

- SKYJACK SJIII-3220 electric scissor lift with 800 lbs capacity, 20’ max vertical lift, on-board battery charger, s/n 607526

ALSO:

Q.C. and inspection equipment including (5) portable gage inspection stations with roll-up doors, air gages, digital gages, snap gages, micrometers, digital inspection equipment and granite surface plates; selection of perishable tooling including carbide cutters, drills, end mills and broaches, carbide inserts, tool holders and setters; (10+) LISTA and ROUSSEAU tool storage cabinets and shelving; FASTENAL index cabinets with fastening hardware and supplies; LARGE SELECTION of SPARE PARTS INVENTORY including ALLEN BRADLEY and REXROTH INDRAMAT PLC controllers and HMI screens, spare boards, spindles and drives, brand name electrical components, hydraulic pumps, drives, motors, cylinders and accumulators, pneumatic cylinders and control valves, selection of BRAND NAME BEARINGS; (5+) AIRVAC drum vacuums; BILXI oil storage tanks with digital metered dispensing guns; cleaning and sanitizing supplies; (2) gas powered pressure washers; racking, shelving and dunnage; office furniture including boardroom tables with chairs, executive desks and furniture, (5+) flat screen tv’s, business machines; stainless steel appliances, lockers and MUCH MORE!