G.S. Die & Design Inc.

Major Heavy Stamping & CNC Machining Event

Date

Wednesday, June 14, 2023

Start Time

10:30 AM EDT

Inspection

Tuesday, June 13 from 9 AM to 5 PM or by appointment. Please email info@corpassets.com to arrange.

Removal

All assets must be removed no later than Friday, July 21 by appointment only. Rigging details below.

Corporate Assets Inc. is pleased to announce its latest acquisition of the assets of G.S. Die & Design Inc.—a best-in-class automotive tooling supplier located in Mississauga, Ontario. While servicing clients such as Mercedes, GM, Ford & Volkswagen, etc., the facility was kept to the highest standards. The assets can be viewed as operational and under power.

Mark Your Calendars for this exceptional TOOL & DIE FACILITY AUCTION to be held on June 14, 2023!

A summary of assets is as follows:

STAMPING DEPARTMENT: CLEARING S4-1000-144-84, 1000 ton straight side stamping press w/ 144” x 84” rolling bolster, COMMAND STAMP press controls, upgraded electrics, hydraulic nuts, 5-20 SPM, etc. SOLD!; DANLY D4-800-145-84, 800-ton straight side stamping press w/ 84” x 142” rolling bolster, 6-15 SPM, 96” windows, etc.; VERSON (REBUILT IN 2008) S2-600-120-72T, 600-ton straight side stamping press w/ 120” x 72” bolster, COMMAND STAMP press controls, 40 SPM, etc.; CLEARING F-4600-132, 600-ton straight side stamping press w/ 84” x 133”bolster; CLEARING F-4400-108, 400-ton straight side stamping press w/ 108” x 60” bolster; (3) COLT CHDR-2000-65, 20,000lb x 65” width capacity mandrel type uncoilers; (3) COLT CERFS-40-60 & CERFS-40-72 servo press feeders; COLT servo straighteners and support equipment

MACHINING DEPARTMENT: SORALUCE (2002) SP-6000 CNC travelling column universal ram-type horizontal machining center; AWEA (2007) BL3018FM, 4-Axis CNC boring/milling machine; AWEA (2009) LP4021, large capacity CNC bridge type vertical machining center; AWEA (2005) SP2016, CNC bridge type vertical machining center; AWEA (2013) AF-1600, high speed CNC vertical machining center; PINNACLE (2016) LV-137, CNC vertical machining center; HAAS (2004) VF-3DAFC, high speed CNC twin pallet vertical machining center; FLOW (2006) 6’ x 12’, 60,000 PSI, CNC integrated flying bridge waterjet cutting machine; NTC TLM 610, 5-AXIS CNC bridge type laser; SODICK (2017) VL400Q, CNC wire type EDM; SODICK (2004) AQ535L, CNC wire type EDM; BROWN & SHARPE EXCEL 9-15-9, bridge type CMM; HEXAGON METROLOGY (2017) RA-7525 SEI ROMER ABSOLUTE 7-AXIS portable coordinate measuring machine; (2) CHEVALIER FSG-1640AD, hydraulic surface grinders; (3) CHEVALIER FSG-618M, surface grinders; (7) FIRST vertical milling machines w/ power drawbars; (2) DAH-LIH DL-V1600, universal bed type milling machines; (7) KAO-MING radial arm drills; (2) ANCHOR portable hydraulic die setters; ZOLLER (2007) SMILE 400, digital tool presetter; SECO EASY SHRINK heat shrink tool setter; CANADIAN CRANE 20t/14t double girder twin hook overhead bridge crane; CANADIAN CRANE 25 ton x 30’ double girder overhead bridge crane; CANADIAN CRANE 20 ton x 30’ double girder overhead bridge crane; (3) CANADIAN CRANE 10 ton x 30’ single girder overhead bridge cranes; CANADIAN CRANE 15 ton x 30’ double girder overhead bridge crane; DETROIT HOIST 5 ton x 30’ single girder overhead bridge crane; YALE 20,000 lb capacity indoor LPG forklift; HYSTER 15,000lb capacity indoor LPG forklift; YALE 5,000lb capacity outdoor LPG forklift; (2) TOYOTA 5,000 lb capacity LPG forklifts; UPRIGHT electric scissor lift; HUGE OFFERING OF: late model welding equipment & accessories, LISTA type tool cabinets, high precision perishable tooling, large T-Slot angle plates and box tables, machine tool accessories, material handling equipment, general machining and fabricating equipment, factory support equipment & MUCH MORE!

Rigging and Removal Details

THE EXCLUSIVE RIGGERS FOR THIS SALE:

| SRMI Inc. | |

| Ian McDougall (English) C: 416 565 5976 pickup@corpassets.com |

Stephane Roy (Francais) C: 819 571 4536 stphane.roy@gmail.com |

| For Lots 155, 159, 160, 164 Lalonde Machinery Movers Ltd. C: 416 285 0024 anthony@lalondemachinerymovers.com |

*All assets must be removed no later than Friday, July 21. Removal at this site is conducted strictly by appointment. All buyers must contact pickup@corpassets.com to set their pick-up appointments upon payment in full.

*Further information on removal details can be found in the Terms & Conditions tab or in the Lot Catalogue.

TRUCKING AND TRANSPORT SERVICES:

Trucking and transport services, including cross-border logistics, are available through Fuze Lo-gistics Inc. Please contact Chris Tan for a firm quote or any questions regarding transportation.

Fuze Logistics Services Inc.

Chris Tan

941-702-3310

machinerylogistics@fuzelogistics.com

STAMPING PRESSES

USI CLEARING S4-1000-144-84 1000 ton capacity mechanical straight side stamping press with (retrofit 2004) REFLEX INTEGRATION COMMAND STAMP PLC control, 84”x144” ram, 84”x144” front-to-back roll-in bolster, 14” stroke, 72” shut height, 14” adjustment, 20 SPM, 67”x42” window, air clutch, palm button control, TOLEDO PWI digital tonnage monitor, safety light curtains, s/n: n/aSOLD!- DANLY D4-800/500-120x84 QDC 800 ton capacity mechanical straight side stamping press with (retrofit 2003) REFLEX INTEGRATION COMMAND STAMP PLC control, 84”x142” ram, 84”x142” left-to-right roll-in bolster, 42” stroke, 82” shut height, 18” adjustment, 8.75-14.88 SPM (continuous), 6.7-11.9 SPM (single stroke), 96”x107” window, TOLEDO PWI digital tonnage monitor, FAGOR DRO, safety light curtains, s/n: 77364701

- VERSON (REBUILT 2008) S2-600-120-72T 600 ton capacity mechanical straight side stamping press with (retrofit) REFLEX INTEGRATION COMMAND STAMP PLC control 72”x120” ram/bed, 20” stroke, 42” shut height, 10” adjustment, 40 SPM, 43”x38” window, air clutch, palm button control, TOLEDO PWI digital tonnage monitor, FAGOR DRO, safety light curtains, s/n: 17237

- CLEARING F-4600-132 600 ton capacity mechanical straight side stamping press with (retrofit) REFLEX INTEGRATION COMMAND STAMP PLC control 78”x126” ram, 84”x133” bed, 14” stroke, 40” shut height with spacers, 56” shut height without spacers, 14” adjustment, 10 SPM, 61”x30” window, palm button control, TOLEDO PWI digital tonnage monitor, FAGOR DRO, safety light curtains, s/n: 49-16436-P

- CLEARING F-4400-108 400 ton capacity mechanical straight side stamping press with (retrofit) REFLEX INTEGRATION COMMAND STAMP PLC control 60”x103” ram, 60”x108” bed, 14” stroke, 35” shut height, 13” adjustment, 16 SPM, 52”x26” window, air clutch, palm button control, FAGOR DRO, safety light curtains, s/n: 36-2664

PRESS FEED LINE EQUIPMENT

- COLT CERFS-40-72HD 72” servo feeder/straightener with COLT digital microprocessor control, (5) roll straightener, s/n: 1141424

- COLT CERFS-40-65 65” servo feeder/straightener with INDRAMAT CTA 4 digital microprocessor control, (5) roll straightener, s/n: 1141292

- COLT CERFS-40-60 60” servo feeder/straightener with INDRAMAT CTA 4 digital microprocessor control, (5) roll straightener, s/n: 1141120

- COLT 38” servo feeder/straightener with INDRAMAT CLM digital microprocessor control, (3) roll straightener, s/n: n/a

- (2) COLT CHDR-2000-65 20,000 lb. capacity motorized traveling uncoilers with 65” max. coil width, 60” O.D., 7.5 HP, hold down arm, s/n: 1201790, 1201926

- COLT CHDR-2000-60 20,000 lb. capacity motorized traveling uncoiler with 60” max. coil width, 60” O.D., 7.5 HP, hold down arm, s/n: 1201951

- AMERICAN STEEL LINE MODEL 1000 6,000 lb. capacity motorized uncoiler, s/n: 6831

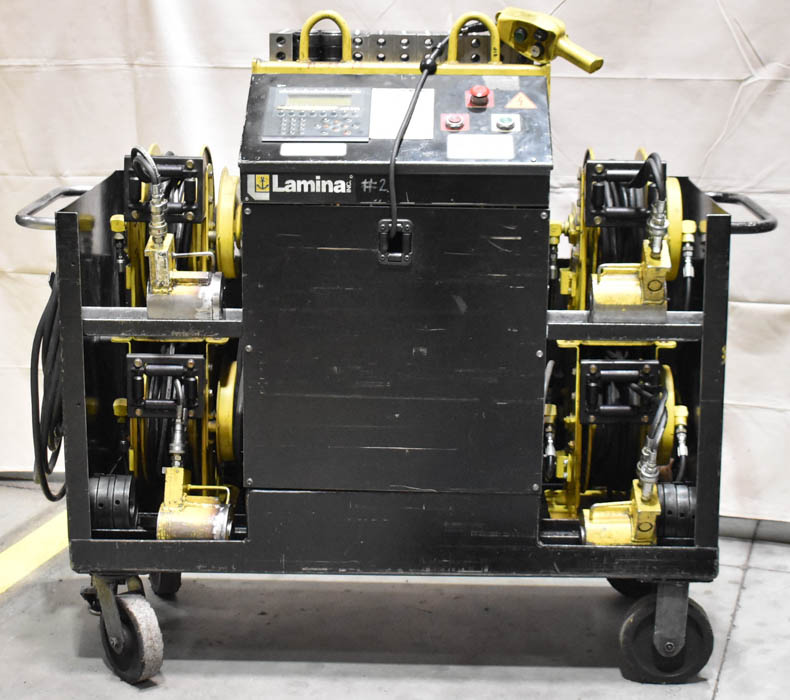

- ANCHOR LAMINA hydraulic die setter with ALLEN-BRADLEY PANELVIEW 300 digital microprocessor control, (4) hydraulic lift cylinders with retractable hose reels, portable cart-mounted frame, s/n: 307160.01

- ANCHOR LAMINA hydraulic die setter with E300 digital microprocessor control, (4) hydraulic lift cylinders with retractable hose reels, portable cart-mounted frame, s/n: 1061

CNC HORIZONTAL BORING/MILLING MACHINE

- AWEA (2007) BL3018FM CNC horizontal boring/milling machine with FANUC SERIES 18i-MB CNC control, 71”x63” rotary table, 1,760 lb. max. table load, travels: X – 118.1”; Y – 70.8”; Z – 39.3”; W – 23.6”; B – 360 deg., spindle speeds to 2400 RPM, 20 HP spindle motor, CAT 50 spindle taper, 40 station ATC, coolant, chip conveyor, s/n: 061170

CNC BRIDGE-TYPE VERTICAL MACHINING CENTERS

- AWEA (2009) LP4021 CNC bridge-type vertical machining center with FANUC SERIES 18i-MB CNC control, 79”x158” table, travels: X – 157.5”; Y – 82.6”; Z – 30”, 39.4” max. distance spindle nose to table top, spindle speeds to 6000 RPM, 30 HP spindle motor, CAT 50 spindle taper, 30 station ATC, M&H laser tool setter, coolant, chip conveyor, 29,056 hours (recorded on meter at time of listing), s/n: 091780

- AWEA (2005) SP2016 CNC bridge-type vertical machining center with FANUC SERIES 18i-MB CNC control, travels: X – 82.7”; Y – 63”; Z – 30”, 39.4” max. distance spindle nose to table top, spindle speeds to 6000 RPM, 30 HP spindle motor, CAT 50 spindle taper, 32 station ATC, coolant, chip conveyor, s/n: 5860

CNC TRAVELLING COLUMN MILLING MACHINE

- SORALUCE (2002) SP-6000 CNC travelling column milling machine with HEIDENHAIN CNC control, 43”x237” table, travels: X – 177.16”; Y – 47.24”; Z – 78.74”, spindle speeds to 4000 RPM, automatic positioning universal head, through-spindle coolant with magnetic filtration, chip conveyor, s/n: 8649

HIGH-SPEED CNC VERTICAL MACHINING CENTERS

- PINNACLE (2016) LV-137 high-speed CNC vertical machining center with MITUBISHI M80 CNC control, 58”x28” table, travels: X – 51.1”; Y – 27.9”; Z – 24”, 28.3” max. distance spindle nose to table top, spindle speeds to 10,000 RPM, 15 HP spindle motor, CAT 40 spindle taper, 30 station ATC, RENISHAW OMI-2 optical receiver/machine interface, coolant, chip conveyor, s/n: 4P11184H8

- AWEA (2013) AF-1600 high-speed CNC vertical machining center with MITSUBISHI M70 CNC control, 32”x67” table, travels: X – 62.9”; Y – 31.4”; Z – 31.4”, 37.9” max. distance spindle nose to table top, spindle speeds to 15,000 RPM, CAT 40 spindle taper, 40 station ATC, RENISHAW OTS optical tool setter, coolant, chip conveyor, s/n: 1600-13012

HIGH-SPEED CNC TWIN PALLET VERTICAL MACHINING CENTER

- HAAS (2004) VF-3D APC high-speed CNC twin pallet vertical machining center with HAAS CNC control, (2) 40”x18” pallets, travels: X – 40”; Y – 20”; Z – 25”, spindle speeds to 15,000 RPM, CAT 40 spindle taper, 24 station ATC, HAAS automatic pallet changer, through-spindle coolant, chip auger, s/n: 39485

CNC WATERJET CUTTING SYSTEM

- FLOW (2006) MODEL 713633-1 CNC integrated flying bridge waterjet cutting machine with FLOWMASTER PC-based CNC control, 86”x168” table, travels: X – 143.7”; Y – 71.8”; Z – 6”, 2.5” material thickness, media recovery, EBBCO CLS-36000IL-3 inline chiller unit (may be sold separately), s/n: 350864

5-AXIS CNC BRIDGE-TYPE LASER CUTTING MACHINE

- NTC TLM610 2000 WATT capacity 5-axis CNC bridge-type laser cutting machine with TDLC-04R CNC control, 74.80” x 122” table, travels: X - 122.04”, Y - 74.80”, Z - 31.49”, B - 200 deg., W - 360 deg., PRC 2200 laser power source with 51,285 hours (recorded on meter at time of listing), AAF INTERNATIONAL cartridge-type dust collector (may be sold separately), KOOLANT KOOLERS liquid chiller (may be sold separately), s/n: 500388

CNC WIRE EDMS

- SODICK (2017) VL400Q CNC wire EDM with SODICK LN2W CNC control, travels: X – 15.75”; Y – 11.8”; Z – 8.6”; U&V – 3.15”x3.15”, 27”x34”x26”D tank dimensions, 1,102 lb. max. workpiece weight, dielectric tank with filtration, s/n: T0166

- SODICK (2004) AQ535L CNC wire EDM with SODICK LQ33W CNC control, travels: X – 21.6”; Y – 13.7”; Z – 11.8”, 30”x44”x14”D tank dimensions, 31”x23” work table, 1,760 lb. max. workpiece weight, dielectric tank with filtration, s/n: 1049

TOOL PRE-SETTERS

- ZOLLER (2007) SMILE 400 digital tool pre-setter with touch screen control, s/n: SM14/4-00271

- SECO EPB EASYSHRINK 20 heat shrink tool pre-setter, s/n: n/a

INSPECTION EQUIPMENT

- HEXAGON METROLOGY (2017) RA-7525 SEI ROMER ABSOLUTE 7-axis portable CMM arm with POLYWORKS WINDOWS PC based control and data acquisition, HEXAGON FP3+RS wireless pack, BRUNSEN heavy duty tripod stand, HEXAGON MODEL RS4 combination laser scanning touch probe, travel case and accessories, s/n: 7525SEI-7076-UC

- ROMER (2005) CMM CIM CORE INFINITE 50245C 7-axis portable CMM arm with (RETROFIT 2010) PERCEPTRON MATROX 4SIGHT M WINDOWS PC based control and data acquisition, PERCEPTRON SCANWORKS V4i laser scanning probe, travel case and accessories, s/n: 129

- BROWN & SHARPE XCEL 9.15.9 CMM with PC DMIS WINDOWS PC based control and data acquisition, 50”x86” granite table, travels: X – 35.4”; Y – 59”; 33.5”, RENISHAW P10MQ touch probe, pendant control, PC & printer, s/n: 0597-2428

- ROCKWELL HR-150A dial-type hardness tester, s/n: 0773

- STARRET 48”x96”x14” granite surface table

CONVENTIONAL MACHINE TOOLS

- DAHLIH (2004) DL-V1600 bed-type universal milling machine with 82”x20” table, travels: longitudinal – 63”; cross – 24”; headstock vertical – 28”; headstock horizontal – 20”, vertical spindle speeds to 1720 RPM, horizontal spindle speeds to 840 RPM, HEIDENHAIN 4-axis DRO, coolant, s/n: 3000090538

- DAHLIH (2003) DL-V1600 bed-type universal milling machine with 82”x20” table, travels: longitudinal – 63”; cross – 24”; headstock vertical – 28”; headstock horizontal – 20”, vertical spindle speeds to 1720 RPM, horizontal spindle speeds to 840 RPM, HEIDENHAIN 4-axis DRO, coolant, s/n: 3000090523

- FIRST LC-20VHS universal milling machine with 50”x10” table, vertical spindle speeds to 4500 RPM, horizontal spindle speeds to 1180 RPM, power table, ALIGN air power drawbar, s/n: 60700664

- BYJC XAE5750/63 universal milling machine with 63”x20” table, speeds to 2050 RPM, MINI-WIZARD DRO, push button control, 2-axis conventional universal head, coolant, s/n: 95041

- (2) FIRST LC-185VS vertical milling machines with 50”x10” table, speeds to 4500 RPM, ALIGN air power drawbar, HEIDENHAIN 2-axis DRO, s/n: 80703544, 80703540

- (3) FIRST LC-185VS vertical milling machines with 50”x10” table, speeds to 4500 RPM, HEIDENHAIN 2-axis DRO, s/n: 60802484, 81003656, 70803172

- FIRST LC-185VS-B vertical milling machine with 50”x10” table, speeds to 4500 RPM, HEIDENHAIN 2-axis DRO, s/n: 40401522

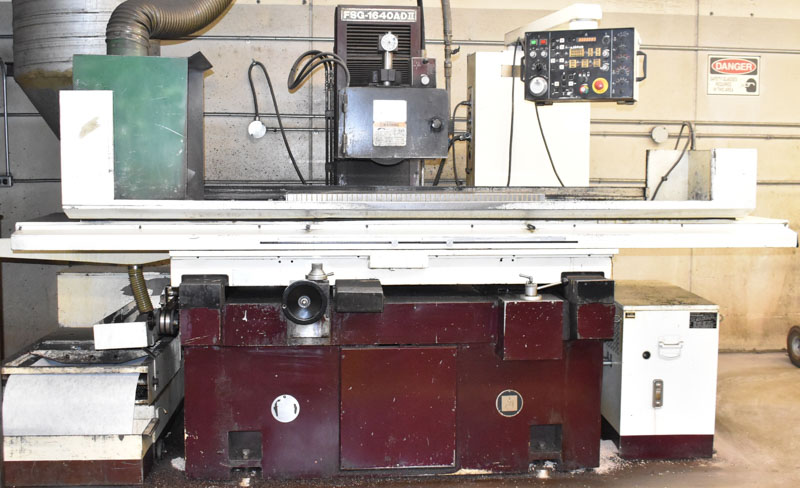

- CHEVALIER FSG-1640AD hydraulic surface grinder with WALKER HAGOU 16”x40” electromagnetic chuck, incremental down feed, 12” wheel, paper band coolant filtration system, coolant, s/n: n/a

- CHEVALIER FSG-16040ADII hydraulic surface grinder with 16”x40” electromagnetic chuck, incremental down feed, 12” wheel, paper band coolant filtration system, coolant, s/n: n/a

- (3) CHEVALIER FSG-618M conventional surface grinders with 6”x18” magnetic chuck, 8” wheel, s/n: A386B057, A389A037, A3921009

- LIAN FENG LF-618 conventional surface grinder with ECLIPSE 6”x18” magnetic chuck, 8” wheel, s/n: 13051

- ZJ (2006) DRILLMASTER Z3050X16 (II) 6’ radial arm drill with speeds to 2000 RPM, 50” column, 24” travel on column, 20”x25”x20”H box table, s/n: 06105095

- (3) KAO MING KMR-1600DH 6’ radial arm drills with speeds to 1380 RPM, 66” column, 36” travel on column, (2) 20”x29”x16”H box tables, s/n: n/a, n/a, n/a

- (3) KAO MING KMR-1100S 4’ radial arm drills with speeds to 1600 RPM, 48” column, 28” travel on column, 20”x26”x16”H box table, s/n: 1309, 10296, R10383

- KAO MING (2004) KMR-700DS 3’ radial arm drill with speeds to 1500 RPM, 37” column, 22” travel on column, 16”x24”x18”H box table, s/n: R70799

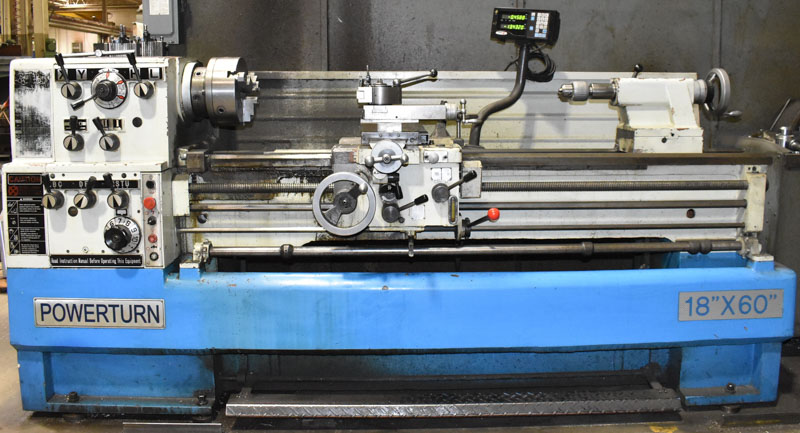

- POWERTURN 18”X60” gap bed engine lathe with 18” swing over bed, 60” distance between centers, speeds to 2000 RPM, 2.5” spindle bore, inch/metric threading, 10” 3-jaw chuck, steady rest, FAGOR 2-axis DRO, s/n: n/a

- T-JAW 700D vertical band saw with 29”x27” table, 28” throat, 15” max. workpiece height, blade cutter/welder, s/n: 9070027

- (2) E-R MAIER KM1012 roll-in vertical band saws with 30”x18” table, 13” throat, 10’2”x3/4” max. blade size, s/n: 52893, 104100

- MFG. UNKNOWN roll-in vertical band saw with 30”x18” table, 13” throat, s/n: n/a

- RAM 18”x6” capacity horizontal band saw with manual vise, s/n: HD12966

- SAMPSON TPR-1316 50”x16 ga. bending rolls with foot pedal, s/n: 1618062

- OTC POWERTEAM 55-ton capacity h-frame hydraulic shop press with 34” between posts, s/n: n/a

- KALAMAZOO combination belt/disc sander with 6” belt, 12” dia. disc, s/n: n/a

- DAREX E-90 tool sharpener with speeds to 3400 RPM, ¼ HP, s/n: n/a

- KBC 14” heavy duty abrasive cut off saw, s/n: n/a

WELDING EQUIPMENT

- LINCOLN ELECTRIC POWER MIG 260 portable MIG welder with digital control, MAXTRAC wire drive system, cables & gun, s/n: M3190101705

- MILLER SYNCROWAVE 250 DX digital TIG welder with built-in chiller, cables & gun, s/n: n/a

- MILLER (2002) SYNCROWAVE 250 DX digital TIG welder with MILLER COOLMATE 3 chiller, cables & gun, s/n: LC207917

- NEDERMAN (2006) FILTERCART portable welding fume extractor with overhead extension arm, s/n: n/a

- NEDERMAN (2002) FILTERBOX 2 HP welding fume extractor with fume snorkel, s/n: 663

OVERHEAD CRANES

- CANADIAN CRANE (2002) 25-ton capacity double girder top-running overhead bridge crane with 30’ span, 16’ height under hook, HULL 25-ton electric hoist, pendant control, s/n: 7046/1

- CANADIAN CRANE (2002) 20/14-ton capacity double girder top-running overhead bridge crane with 30’ span, 16’ height under hook, 20-ton capacity primary electric hoist, 14 ton capacity auxiliary electric hoist, pendant control, s/n: 7046/2

- CANADIAN CRANE & HOIST 20-ton capacity double girder top-running overhead bridge crane with 30’ span, 16’ height under hook, SWF 20-ton main electric hoist, SWF 14-ton secondary electric hoist, pendant control, s/n: n/a

- CANADIAN CRANE & HOIST 15-ton capacity double girder top-running overhead bridge crane with 30’ span, 16’ height under hook, SWF 15-ton capacity electric hoist, pendant control, s/n: n/a

- CANADIAN CRANE (2002) 10-ton capacity single girder top-running overhead bridge crane with 30’ span, 16’ height under hook, SWF 10-ton capacity electric hoist, pendant control, s/n: 7457/1

- CANADIAN CRANE & HOIST 10-ton capacity single girder top-running overhead bridge crane with 30’ span, 16’ height under hook, SWF 10-ton electric hoist, pendant control, s/n: n/a

- CANADIAN CRANE & HOIST 10-ton capacity single girder top-running overhead bridge crane with 30’ span, 16’ height under hook, 10-ton electric hoist, pendant control, s/n: n/a

- DETROIT HOIST 5-ton capacity single girder top-running overhead bridge crane with 30’ span, 16’ height under hook, 5-ton electric hoist, pendant control, s/n: n/a

AIR COMPRESSORS

- ATLAS COPCO (2002) GA55 75 HP rotary screw air compressor with 132 PSI, 324 CFM, 3600 RPM, 58,182 hours (recorded on meter at time of listing), s/n: AII476755

- KAESER (2000) BS61 50 HP rotary screw air compressor with 110 PSIG, 240 CFM, 1800 RPM, s/n: 1013

- ATLAS COPCO GA30 40 HP rotary screw air compressor with 132 PSI, 174 CFM, 3600 RPM, s/n: AII320817

- ULTRA AIR UA200AC refrigerated air dryer with 1.0 HP, 200 PSIG, s/n: U-25609-4

ROLLING STOCK

- YALE L5-200-MAS 20,000 lb. capacity LPG forklift with 124” max. lift height, single stage mast, solid tires, s/n: AK-132762

- HYSTER S150A 15,000 lb. capacity LPG forklift with 129” max. lift height, 2-stage mast, solid tires, s/n: A024D03095V

- (2) TOYOTA 42-6FGCU25 4,900 lb. capacity LPG forklifts with 189” max. lift height, 3-stage mast, side shift, multi-surface tires, s/n: 80292, 74711

- YALE A409611 5,000 lb. capacity LPG forklift with 128” max. lift height, 2-stage mast, solid tires, s/n: GLC050RCJUAF08

- CLARK ST30B 3000 lb. capacity 24V electric walk-behind stacker forklift with 130” max. lift height, s/n: ST245-164-3306FA

- UPRIGHT MX19 24V electric scissor lift with 500 lb. capacity, 22.5”x98.5” platform, 25’ max. work height, on-board charger, s/n: n/a

FACTORY SUPPORT EQUIPMENT

- PLYMOVENT MFE-4 20 HP cartridge-type dust collector with (8) cartridge filters, s/n: n/a

- EMPIRE EF-2430 ECONO-FINISH suction blast cabinet with dust collector, s/n: C-7572

- FACTORY CAT MODEL 28 electric walk-behind floor scrubber, s/n: n/a

- MOTIVATION 500 lb. capacity free standing jib arm with 8’ span, 8.5’ height under hook, JET ¼ ton capacity electric hoist, s/n: n/a

- KLETON 500 lb. capacity wall-mounted jib arm with 8’ span, JET ¼ ton capacity electric hoist, s/n: n/a

ALSO:

- HUGE QUANTITY of CAT 50 & CAT 40 conventional and heat shrink tool holders; machine tool accessories including 72”x72” heavy duty angle plate, (2) 98”x40” heavy duty angle plates, machine vises, rotary tables, setup blocks and fixtures; INSPECTION EQUIPMENT including granite surface plates, precision vises, height gauges, gauge blocks; machine. LARGE SELECTION of LISTA-type multi-drawer tool cabinets; (50+) engineered steel saw horses; lifting magnets; lifting chains; swivel eyebolts; lifting shackles; power tools; hand tools; PERISHABLE TOOLING comprising drills, end mills, reamers, carbide insert cutters, carbide insert face mills, carbide insert boring bars, carbide inserts; work benches; shop carts; die racks and MUCH MORE!