MillerKnoll, Inc.

75,000+ Sq. Ft. Metal Fabricating Facility

Date

Tuesday, October 17, 2023

Start Time

10:30 AM EDT

Inspection

Monday, October 16 from 9 AM to 4 PM.

Removal

All assets must be removed no later than Friday, November 17 by appointment only. Rigging details below.

Industry

FEATURING: LARGE CAPACITY monorail paint line w/ 3 stage stainless steel wash and bake oven; ALLSTEEL 160-10 160 ton x 10’ hydraulic press brake; (3) ALLSTEEL 120-12 120 ton x 12’ CNC hydraulic press brakes; AMADA RG-100 100 ton x 10’ hydraulic press brake; ACCURPRESS 710010 100 ton x 10’ hydraulic press brake; ALLSTEEL 45-8 45 ton x 8’ hydraulic press brake; BLOW SD 4094 400 ton straight side press; MECON COMPACT SERVO PRESS FEEDLINE; GOITI NFR 125 ton C-frame press; NIAGARA A5 90 ton OBI press; BLOW GD-60-25-77 60 ton C-frame press; BROWN BOGGS S17.5J 60 ton OBI press; BROWN BOGGS 15LW 40 ton OBI press; (3) MECON 60MDCH-24 6000lbs. capacity uncoilers; AMADA PEGA-304040 30 ton CNC turret punch; AMADA ARIES 245 20 ton CNC turret punch; WYSONG 1025 10’ mechanical shear with ¼” capacity; FORWARDFM-250ATG-IM CNC vertical machining center; ELUMATEC SBZ122 CNC profile machining center; (2) NACHI (2000) SC06F-02 robotic welding cells; (5) rocker arm type spot welders; ELUMTEC AF223 horizontal mill; (2) ELUMATEC DG142 twin head up acting miter saws; (10+) Sections of late model heavy duty cantilever material storage racking; GARDNER-DENVERCMQL0 75HP rotary screw compressor; ALSO FEATURING A LARGE OFFERING OF: press brake tooling, punch tooling, adjustable racking, numerous maintenance and spares departments, material handling equipment, production support related assets, factory support equipment & MUCH MORE!

Rigging and Removal Details

THE EXCLUSIVE RIGGER FOR THIS SALE IS:

Titan Machinery Movers

Jordan Whicher

C: 905 875 9768

jwhicher@meehans.ca

*All assets must be removed no later than Friday, November 17. For everyone’s safety removal at this site is conducted strictly by appointment only. All machinery buyers must contact Jordan Whicher at 905 875 9768 to set their pick-up appointments upon payment in full.

*Further information on removal details can be found in the Terms & Conditions tab or in the Lot Catalogue.

TRUCKING AND TRANSPORT SERVICES:

Trucking and transport services, including cross-border logistics, are available through Fuze Logistics Inc. Please contact Chris Tan for a firm quote or any questions regarding transportation.

Fuze Logistics Services Inc.

Chris Tan

514.799.4162

machinerylogistics@fuzelogistics.com

PAINT LINE

- CONSISTING OF J.P. FINISHING 36”x63” opening, 3 stage stainless steel wash w/ 1 million BTU tube burner, 1.5 million BTU TEMPRITE gas fired oven, (2) 144”x96” manual spray booths, RANSBURG quick change color stack system, (4) GRACO GLATON paint pumps, (4) paint heaters, (7) pressure pots, flash off and cool down tunnel, approx. 675’ allied conveyor chain, s/n NA (components may be sold separately)

PRESS BRAKES

- ALLSTEEL 160-10 160 ton x 10’ hydraulic press brake with AUTOMEC CNC 150 AUTO GAUGE back gauge control, shadow 9 light curtains, 102” between housings, 7.5” throat depth, 0-10” stroke, 19” open height, 30 HP, 550v/60hz/3ph, s/n 1715

- ALLSTEEL 120-12 120 ton x 12’ CNC hydraulic press brake with AUTOMEC CNC 150 AUTO GAUGE back gauge control, shadow 9 light curtains, 126” between housings, 8” throat depth, 0-8” stroke, 17” open height, 25 HP, 550v/60hz/3ph, s/n 2303.

- ALLSTEEL 120-10 120 ton x 10’ hydraulic press brake with AUTOMEC CNC 1000 auto gauge back gauge control, shadow 9 light curtains, chiller, 102” between housings, 8” throat depth, 8” stroke, 17” open height, 25 HP, 550v/60hz/3ph, s/n 2281.

- ALLSTEEL 120-10 120 ton x 10’ hydraulic press brake with TTP chiller, back gauge, shadow 9 light curtains, 102” between housings, 8” throat depth, 0-8” stroke, 17” open height, 20 HP, 550v/60hz/3ph, s/n 2044.

- AMADA RG-100 100 ton x 10’ hydraulic press brake with AMADA NC9-EXII CNC back gauge control, 100.5” between housings, 15.76” throat depth, 3.94” stroke, 14.58 open height, s/n 105095

- ACCURPRESS 710010 100 ton x 10’ hydraulic press brake with ACCURPRESS ETS control, SHADOW VI light curtains, 102” between housings, 10” throat depth, 8” stroke, 18” open height, 575v/60hz/3ph, s/n 6950

- ALLSTEEL 45-8 45 ton x 8’ hydraulic press brake with AUTOMEC CNC 99 AUTO GAUGE back gauge control, shadow 9 light curtains, 77.25” between housings, 88.5” throat depth, 0-6” stroke, 15” open height, 15 HP, 550v/60hx/3ph, s/n 807

PRESS DEPARTMENT

- BLOW SD 4094 400 ton straight side press with SMARTPAC WINTRISS press automation control, 12” stroke, 8” adjustment, 48”x84” bed, 48”x84” ram, 22 SPM, 16”x19” windows, 80psig air clutch, 90psig pinch roller, 40 HP, s/n SDG 400 6567

- MECON COMPACT SERVO PRESS FEEDLINE consisting of: MECON 400FSP241 servo feeder with 25” with capacity s/n 2644N203, MECON 100BTJ24 10,000 lbs. capacity uncoiler with MECON 1000-PR coil cart, 10,000 lbs. capacity, MECON 6PR24 coil balancer s/n 2903N23

- GOITI NFR 125 ton C-frame press with 16.73” shut height, 3.7” adjustment, 48 strokes per minute, 42.5”x25.5” bed, 24.5”x14.5” ram, shadow 9 light curtains, WPC WINTRISS clutch/brake control, s/n 87-48. (I.D. 1301)

- NIAGARA A5 90 ton OBI press with 9” stroke, 18” shut height, 4.5 adjustment, SHADOW VI light curtains, 39”x27” bed, 18”x19” ram, WPC WINTRISS clutch/brake control, s/n n/a. (ID 1316)

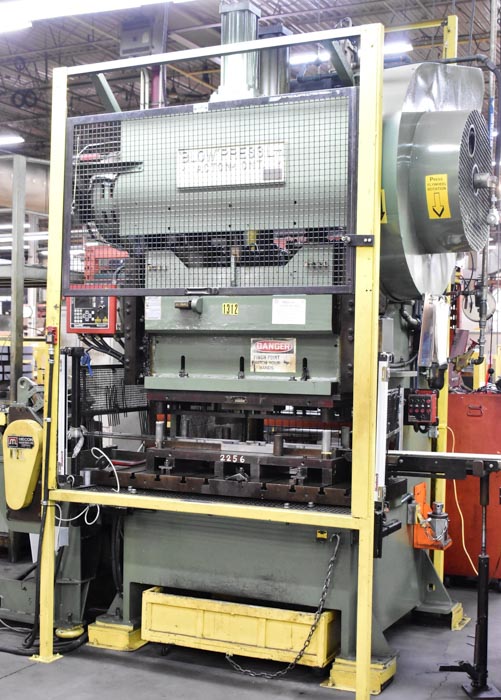

- BLOW GD-60-25-77 60 ton C-frame press with 62”x21.5” bed, 42”x18” ram, shadow 9 light curtains, WPC WINTRISS clutch/brake control, s/n n/a. (I.D.1312)

- BROWN BOGGS S17.5J 60 ton OBI press with 5” stroke, 12 3/8” shut height, 3” adjustment SHADOW VI light curtains, 22.25”x 32” bed, 21”x16” ram, WPC WINTRISS clutch/brake control, s/n n/a. (I.D.1304)

- BROWN BOGGS 15LW 40 ton OBI press with 2.5” stroke, 8.25”-10.5” shut height, 2.5” adjustment, 110 strokes per minute, 28”x18” bed, 7.25”x10” ram, SHADOW 8 light curtains, WPC WINTRISS clutch/brake control, s/n 78145.

- BARRIE WELDING AND MACHINE air feeder with 21.5” opening, s/n FSI8-42870 03

- MECON pneumatic feeder with 14” opening, s/n n/a

- MECON pneumatic feeder with 13” opening, s/n n/a

- MECON 60MDCH-24 6000lbs. capacity uncoiler, s/n 69801

- MECON 60M24H 6000lbs. capacity uncoiler, s/n 2067N30

- MECON 60MDCH24 6000lbs. capacity uncoiler, s/n 69703

CNC TURRET PUNCH

- AMADA PEGA-304040 30 ton CNC turret punch with AMADA-FANUC-P A02B-0060-B012 CNC control, 58 station turret, AMADA MP-1012NF auto loader, 81”x44.5” roller table, 48” throat, s/n P3441833

- AMADA ARIES 245 20 ton CNC turret punch with AMADA METRICS AMADAN04PA CNC control, 19 station turret, 96”x47” roller table, pneumatic clamping 40” throat, s/n 24500865

MECHANICAL SHEAR

- WYSONG 1025 10’ mechanical shear with ¼” capacity, WYSONG PC100 control, STEELTECH MACHINERY LTD. 120”x73” off-cut belt conveyor with 500lbs. capacity, s/n P37-987

MACHINING CENTERS

- FORWARD FM-250ATG-IM CNC vertical machining center with FRANK PHENIX CNC control, 60”x12” t-slot table, BT40 spindle, 16 ATC, TRAVELS X- 50”, Y-19.75”, Z-21.25” speed to 3600rpm, coolant, chip auger, s/n MF00136.

- ELUMATEC SBZ122 CNC profile machining center with ELUMATEC E550 CNC control, HSK 63 tool holder, RECKERTH spindle, coolant cooler, TRAVELS: X-138”, Y-14”, Z-11”, speed up to 21,000rpm, 2 ATC with 4 station tool holder, 4 position angle head attachment, s/n 12230300088

WELDING DEPARTMENT

- NACHI (2000) SC06F-02 robotic welding cell with NOCHI B003H612 6 axis welding robot, NACHI AW controller, DAIHEN DP 500 digital inverter, ALMEGA tip cleaning kit, s/n 31874.

- NACHI (2000) SC15F-02 robotic welding cell with NOCHI B008H438 6 axis welding robot, NACHI AW controller, DAIHEN DP 400 digital inverter, ALMEGA tip cleaning kit, s/n 3302A.

- WELD-O-MATIC L 150kva projection welder with 15” throat, 14”x10” bed, 14”x10” ram, s/n 3228

- ASPA ZGD-1060 160kva projection welder with 15” throat, 14”x10” bed, 14”x10” ram, s/n 01030027

- WELD-O-MATIC AF-2A 75kva rocker arm spot welder with 36” throat, s/n 2818

- WELD-O-MATIC AF-2A 75kva rocker arm spot welder with 32” throat, s/n 2370

- (2) HOBART RC-200 MIG welder with HOBART 17 wire feeds, s/n n/a

- BERG PA-3 chiller, s/n W00776A-AA1-0701

- UNITROL PROCESS 8055 chiller with 20gpm @ 35psig, 18,000btu/hr, s/n 0712891

- DIVERSI-TECH FRED DM6400 fume extractor, s/n DM0070

- DIVERSI-TECH FRED DM1400 portable fume extractor, s/n DMA0080.

CONVENTIONAL MACHINERY

- ELUMTEC AF223 horizontal mill with AER PRO SB 1500 vacuum chip collector, s/n 2230024192

- ELUMATEC DG142 twin head up acting miter saw with 19.5” blade, pneumatic clamping, air over oil system, blade coolant, KRAEMER KTM AC-5 chip collector, s/n 1429333163

- ELUMATEC twin head up acting saw with ELUMATEC E111 DRO, 16.5” blade, pneumatic clamping, pneumatic blade feed system, blade coolant, KREAMER chip vacuum collector, s/n n/a.

- MILLER KNOLL multi head vertical pneumatic/hydraulic punch machine, s/n n/a

- MILLER KNOLL multi spindle corner post drill machine, s/n KN0474

- CHEVALIER FSG-618 mechanical surface grinder with 6” grinding wheel, 17.75”x6” WALKER-HAGOU magnetic chuck, s/n 02C-4792

- WALTER CS200 cold cut saw with 10” blade, coolant, 5.5” vice, s/n 34198

- (2) FIRST LCN-14 bench type drill press, s/n 7125775, 72118620

- GENERAL INTERNATIONAL floor type drill press, s/n 7620/604

- BAXTER VERTICUT 115B roll-in type vertical band saw, s/N 4717

- MFG UNKNOWN double head sander/polisher with TORIT dust collector, s/n n/a

- ENERPAC 30 ton hydraulic shop press with ENERPAC hydraulic power pack, s/n n/a

FACTORY SUPPORT EQUIPMENT

- (10+) Sections of late model heavy duty cantilever material storage racking

- TORONTO ELECTRIC 5 ton monorail with SHAW BOX 5 ton electric hoist with pendent control, s/n n/a

- MOTIVATION 3 ton free standing jib arm with CM 2 ton electric hoist with pendent control, s/n n/a

- MOTIVATION 2 ton free standing jib arm with YALE 1 ton electric hoist with pendent control, s/n n/a.

- BISON 10,000lbs. capacity coil lifting c-hook, s/n n/a

- GARDNER-DENVER CMQL0 75HP rotary screw compressor, 61706hrs, s/n M50755

- PIONEER P400A air dryer, s/n 19542 KF WB.

- JRI SPRINGFEILD parts washer with 24”x 94” conveyor, s/n n/a

ALSO:

- FEATURING A LARGE OFFERING OF: press brake tooling, punch tooling, adjustable racking, numerous maintenance and spares departments, material handling equipment, production support related assets, factory support equipment & MUCH MORE!