(Court Approved Receivership Sale of)

Toolplas Systems Inc.

Major 3-Day & Multimillion Dollar Late Model CNC Machining Event!

Date

Tuesday, June 15, 2021 - Thursday, June 17, 2021

Start Time

9:00 AM EDT

Inspection

BY APPOINTMENT ONLY. Please email info@corpassets.com to arrange a date and time.

Removal

All assets must be removed no later than Friday, July 30 BY APPOINTMENT ONLY. Please email info@corpassets.com to arrange.

Location

Assets Located in Windsor, ON

Industry

Corporate Assets Inc. is pleased to announce its recent acquisition of the assets of Toolplas Systems Inc.—an industry leader in the complex design and manufacturing of plastic injection molds and tools used in the automotive industry. The two facilities have exceptional manufacturing capabilities and can produce molds for machines up to 4000 ton in size. This is an incredible opportunity to acquire late model CNC machinery as new as 2020! Mark your calendars for this upcoming 3-Day Public Auction!

REMOVAL DETAILS

Due to restrictions currently in effect, all removals for this auction will be conducted by appointment only.‘Drop in’ pick-ups will not be allowed, and we ask that all buyers comply with the appointment schedule. Buyers showing up on site without an appointment will be turned away. There will be no exceptions as this is necessary to maintain social distancing rules in effect. Thank you for your understanding.

REMOVAL SCHEDULE:

Small Items, Box Lots and Small Machinery – June 21 onwards

Machinery and Heavy Equipment – June 28 onwards

SMALL ITEMS REMOVAL:

To schedule a pickup appointment for small items please email: pickup@corpassets.com

MACHINERY AND HEAVY EQUIPMENT REMOVAL:

THE EXCLUSIVE RIGGER AT THIS SALE IS:

Moir-Ferriss Machinery Moving Inc.

Chad Ferriss

(519) 919-9614

chad@moir-ferriss.com

CNC GUN DRILLS

- UNISIG (installed brand new in September 2020 - over $1.9M USD) USC-M38 5-axis combination CNC gun drilling and milling machine with HEIDENHAIN iTNC 640 CNC control, 2” max gun drilling diameter, 1.5” max BTA/STS drilling diameter, 59.10” max drilling depth, 39.37” x 47.20” table, 33,000 lbs table loading capacity, travels X-86.60”, Y-66.90”, Z-39.37”, W-19.70”, U-72.00”, B-360,000 positions, 20 hp drilling spindle with speeds to 5,000 rpm, 20 hp milling spindle with speeds to 4500 rpm in (2) ranges, CAT 50 milling spindle taper, 120 station tool hive with SIEMENS touch screen HMI, upgraded 2,000 psi high pressure programmable coolant with filtration, chip conveyor, 277-480v/3ph/60hz, s/n 2005 [PLANT 2]

- IMSA (2006) MF 1000 – MF 1200 BB L CNC gun drill with SELCA S4000 CNC control, 47.25"x59" rotary table, speeds to 4250 RPM, BT 40 taper milling head, milling head speeds to 4500 RPM, 20 station ATC, hydraulic power pack, FILTRA chip conveyor, full enclosure, s/n: 06.195.0115 [PLANT 2]

HIGH SPEED 6-AXIS CNC MACHINING CENTERS

- MAKINO (2013) MCC2013 VG 6-axis CNC machining center with MAKINO PROFESSIONAL 5 CNC control, 59” x 47” table, 22,000 lbs max table loading capacity, travels X-78.74”, Y-51.18”, Z-51.18”, A-60 degrees (+/-30), C-370 degrees (+/-185), B- 360 degrees, speeds to 12,000 rpm, HSK-A100 spindle taper, 120 station ATC, 1200 psi high pressure through spindle coolant, filtration, chip conveyor, RENISHAW probing system, 460v/3ph/60hz, s/n 190 [PLANT 2]

- MAKINO (2013) MCC2013 VG 6-axis CNC machining center with MAKINO PROFESSIONAL 5 CNC control, 59” x 47” table, 22,000 lbs max table loading capacity, travels X-78.74”, Y-51.18”, Z-51.18”, A-60 degrees (+/-30), C-370 degrees (+/-185), B- 360 degrees, speeds to 12,000 rpm, HSK-A100 spindle taper, 120 station ATC, 1200 psi high pressure through spindle coolant, filtration, chip conveyor, RENISHAW probing system, 460v/3ph/60hz, s/n 178 [PLANT 2]

HIGH SPEED 5-AXIS CNC MACHINING CENTERS

- MAKINO (NOV 2018) V90S 5-axis CNC machining center with MAKINO PROFESSIONAL 6 CNC control, 78.74” x 51.18” table, 11,000 lbs max table loading capacity, travels X-78.74”, Y-51.18”, Z-31.49”, A-60 degrees (+/-30), C-120 degrees (+/-60), speeds to 20,000 rpm, HSK-A63 spindle taper, 40 station ATC, high pressure through spindle coolant, filtration, chip conveyor, RENISHAW OMI-2 probing system with RENISHAW RMP600 touch probe, 460v/3ph/60hz, s/n 83 [PLANT 2]

- RODERS TEC (2017) RXP601DSHZ2 5-axis high speed CNC machining center with ROEDERS TEC RMS6 CNC control, 15.74” dia. table, Travels: X-21.25”, Y-25.00”, Z-15.74”, A-230 deg. (+/- 115), B-360 deg., 21.06” max. distance spindle nose to table top, speeds to 60,000 RPM main spindle, speeds to 36,000 RPM secondary spindle, HSK-E25 main spindle taper, HSK-E50 secondary spindle taper, 25 station HSK-E50 ATC, 26 station HSK-E25 ATC, coolant, chip augers/conveyor, RENISHAW OMI-2 system with RENISHAW OMP-400 touch probe, laser tool measuring system, 400V/3PH/60HZ, s/n: 15154-4 [PLANT 2]

- GROB (2014) G550 5-axis twin pallet CNC machining center with HEIDENHAIN iTNC 530 CNC control, 24.75”x24.75” drilled and tapped pallets, Travels: X-31.49”, Y-40.15”, Z-40.15”, A-225 deg. (-180/+45), B-360 deg., speeds to 16,000 RPM, 42/33.5 HP spindle motor, HSK63A spindle taper, 120 station ATC (2x60), high pressure through spindle coolant, filtration, chip conveyor, RENISHAW OMI-2 system with RENISHAW OMP60 touch probe, BLUM laser tool measuring system, 480V/3PH/60HZ, s/n: G-551-1347 [PLANT 2]

- GROB (2012) G350 5-axis CNC machining center with HEIDENHAIN iTNC 530 CNC control, 22.25” dia. table, Travels: X-23.62”, Y-30.31”, Z-31.69”, A-240 deg. (-180/+60), B-360 deg., speeds to 16,000 RPM, 50/38 HP spindle motor, HSK-63A spindle taper, 34 station ATC, high pressure through spindle coolant, filtration, chip conveyor, RENISHAW OMI-2 system with RENISHAW OMP60 touch probe, BLUM laser tool measuring system, 480V/3PH/60HZ, s/n: G-350-1224 [PLANT 2]

- PARPAS DIAMOND 35 5-axis gantry-type CNC vertical machining center with HEIDENHAIN CNC control, 63”x96” table, Travels: X-87”, Y-59”, Z-39”, C- +/- 370 deg., A- +/- 105 deg., speeds to 20,000 RPM, 40 HP spindle motor, HSK-63A spindle taper, 24 station ATC, coolant, chip conveyor, 575V/3PH/60HZ, s/n: SEDI 028 [PLANT 2]

- FIDIA (2002) K 411 5-axis CNC vertical machining center with FIDIA C20 CNC control, 59”x197” table, Travels: X-165.00”, Y-43.30”, Z-39.37”, C-360 deg. (+/-180), A-150 deg. (-90/+60), speeds to 24,000 RPM, HSK-63E spindle taper, 42 station ATC, coolant, chip filtration, chip conveyor, 600V/3PH/60HZ, s/n: K 411-012 [PLANT 2]

HIGH SPEED CNC VERTICAL MACHINING CENTERS

- MAKINO (2012) F3 CNC vertical machining center with MAKINO PROFESSIONAL 5 touchscreen CNC control, 33.46”x19.68” table, Travels: X-25.59”, Y-19.68”, Z-17.70”, speeds to 30,000 RPM, HSK-F63 spindle taper, 20/14.75 HP spindle motor, 30 station ATC, BLUM laser tool measuring system, chip auger, DONALDSON TORIT DFO3-3 cartridge-type dust collector, 208V/3PH/60HZ, s/n: V140297 [PLANT 2]

- MAKINO (2008) V99L (#50) CNC vertical machining center with MAKINO PROFESSIONAL 5 CNC control, 39.37”x90.55” table, Travels: X-78.74”, Y-39.37”, Z-31.50”, speeds to 18,000 RPM, HSK-A100 spindle taper, 30 station ATC, coolant, chip conveyor, touch tool measuring system, MARPOSS measuring system, 400V/3PH/50-60HZ, s/n: V99-115 [PLANT 2]

- MAKINO (2008) V56 GRAPHITE CNC vertical machining center with MAKINO PROFESSIONAL 5 touchscreen CNC control, 41.33”x21.65” table, Travels: X-35.43”, Y-21.65”, Z-16.92”, HSK-A63 spindle taper, speeds to 12,000 RPM, 20 HP spindle motor, 25 station ATC, chip conveyor, AMANO PIE-45M 3 HP cyclonic-type dust collector, MARPOSS measuring system with MARPOSS T25 touch probe, 400V/3PH/60HZ, s/n:V56-1164 [PLANT 2]

- OKUMA (DEC-2014) GENOS M560-V CNC vertical machining center with OKUMA OSP-P300M CNC control, 22”x51” table, Travels: X-41.34”, Y-22.05”, Z-18.11”, speeds to 15,000 RPM, 30/25 HP spindle motor, CAT 40 spindle taper, 32 station ATC, *UPGRADED* 200 PSI through spindle coolant, coolant filtration, chip augers/conveyor, 220-480V/3PH/60HZ, s/n: 182015 [PLANT 2]

- AWEA YAMA SEIKI (2012) AF-1250 CNC vertical machining center with FANUC SERIES 31i-MODEL B CNC control, 24.50”x53.25” table, Travels: X-49.30”, Y-24.50”, Z-24.50”, speeds to 15,000 RPM, 20/25 HP spindle motor, CAT 40 spindle taper, 38 station ATC, chip flush, chip conveyor, 220V/3PH/60HZ, s/n: 1250-12013 [PLANT 2]

- SWI (2014) TRAK LPM 4-axis CNC vertical machining center with PROTO TRAK PMX CNC control, 19.5”x35.5” table, Travels: X-31”, Y-18.5”, Z-21”, 24” max. distance spindle nose to table top, 1000 lb. max. table capacity, speeds to 8000 RPM, CAT 40 spindle taper, 16 station ATC, coolant, chip auger, SWI (2015) 28060 8” dia. 4th axis rotary table with tailstock (may be sold separately), 220V/3PH/60HZ, s/n: 153DJ004 [PLANT 2]

- SWI (2014) TRAK LPM CNC vertical machining center with PROTO TRAK PMX CNC control, 19.5”x35.5” table, Travels: X-31”, Y-18.5”, Z-21”, 24” max. distance spindle nose to table top, 1000 lb. max. table capacity, speeds to 8000 RPM, CAT 40 spindle taper, 16 station ATC, coolant, chip auger, 220V/3PH/60HZ, s/n: 144DJ264 [PLANT 2]

- SWI (2013) TRAK LPM CNC vertical machining center with PROTO TRAK PMX CNC control, 19.5”x35.5” table, Travels: X-31”, Y-18.5”, Z-21”, 24” max. distance spindle nose to table top, 1000 lb. max. table capacity, speeds to 8000 RPM, CAT 40 spindle taper, 16 station ATC, coolant, chip auger, 220V/3PH/60HZ, s/n: 144DJ169 [PLANT 2]

- SWI (2012) TRAK LPM 4-axis CNC vertical machining center with PROTO TRAK PMX CNC control, 19.5”x35.5” table, Travels: X-31”, Y-18.5”, Z-21”, 24” max. distance spindle nose to table top, 1000 lb. max. table capacity, speeds to 8000 RPM, CAT 40 spindle taper, 16 station ATC, coolant, chip auger, SWI (2015) 28060 8” dia. 4th axis rotary table with tailstock (may be sold separately), 220V/3PH/60HZ, s/n: 122DJ446223 [PLANT 2]

- OKUMA (2007) ACE CENTER MB-56VB CNC vertical machining center with OKUMA OSP-P200M CNC control, 22”x51” table, Travels: X-41.34, Y-22.05, Z-18.11, speeds to 12,000 RPM, 30/25 HP spindle motor, CAT 50 spindle taper, 32 station ATC, *UPGRADED* 200 PSI through spindle coolant, coolant filtration, chip flush, chip conveyor, 220-480V/3PH/60HZ, s/n: 133293 [PLANT 2]

- PHOENIX KAFO (2001) VMC-21100 CNC vertical machining center with HEIDENHAIN CNC control, 39”x94” table, Travels: X-84.65”, Y-39.37”, Z-31.50”, speeds to 6000 RPM, CAT 50 spindle taper, 30 station ATC, coolant, chip tray, 380-220V/3PH/60HZ, s/n: 035184 (not in service) [PLANT 2]

HIGH SPEED CNC GANTRY TYPE VERTICAL MACHINING CENTERS

- DYNAMIC SPEED (2010) GT-3016V gantry-type vertical machining center with HEIDENHAIN iTNC530 CNC control, 63”x130” table, CAT 50 spindle taper, 20 station ATC, coolant, chip auger, chip conveyor, laser tool measuring system, 400V/3PH/60HZ, s/n: 210016 [PLANT 2]

- AWEA (2005) SP3016HSS gantry-type CNC vertical machining center with FANUC SERIES 18i-MB CNC control, 59”x82.5” table, Travels: X-120.55”, Y-63”, Z-30”, speeds to 15,000 RPM, 19 station ATC, CAT 40 spindle taper, coolant, chip conveyor, laser tool measuring, 220V/3PH/60HZ, s/n: 5756 [PLANT 2]

- AWEA (2005) SP2016HSS gantry-type CNC vertical machining center with FANUC SERIES 18i-MB CNC control, 59”x82.5” table, Travels: X-82.70”, Y-63”, Z-30”, speeds to 15,000 RPM, 19 station ATC, CAT 40 spindle taper, coolant, chip conveyor, laser tool measuring system, 220V/3PH/60HZ, s/n: 4738 [PLANT 2]

- PARPASFAMU (1998) PHS-812 gantry-type CNC vertical machining center with FAMU-SIEMENS CNC control, 31.5”x52” table, Travels: X-47.25”, Y-31.50”, Z-19.75”, speeds to 22,000 RPM, HSK-A63 spindle taper, 20 station ATC, coolant, chip tray, 480V/3PH/60HZ, s/n: 311P/3 (not in service) [PLANT 2]

HIGH SPEED CNC HORIZONTAL MACHINING CENTERS

- OKUMA (2016) MA-12500H SPACE CENTER twin pallet CNC horizontal machining center with OKUMA OSP-P300M touch screen CNC control, (2) 49"×49" drilled and tapped pallets with 11,000 lb. capacity, travels: X - 86.61", Y - 62.99", Z - 64.96", B (pallet rotation) - 360 degrees, max. distance spindle center to pallet surface 64.96", max. distance spindle end to pallet center 73.82", spindle speeds to 8000 RPM, CAT 50 taper, 177 station ATC, 60 HP, through-spindle and shower coolant, chip conveyor, automatic pallet changer with hydraulic clamping, rapid traverse, RENISHAW RMP60 auto gauging, ABSO scales, collision avoidance system, super-NURBS, turn cut function, cutting time (recorded at time of listing) ONLY 4194 hrs, s/n: 186906 (PURCHASED NEW IN 2018) (SOLD BY PHOTO – LOCATED IN TENNESSEE, USA)

- OKUMA (2014) MA-12500H SPACE CENTER twin pallet CNC horizontal machining center with OKUMA OSP-P300M touch screen CNC control, (2) 49"×49" drilled and tapped pallets with 11,000 lb. capacity, travels: X - 86.61", Y - 62.99", Z - 64.96", B (pallet rotation) - 360 degrees, max. distance spindle center to pallet surface 64.96", max. distance spindle end to pallet center 73.82", spindle speeds to 8000 RPM, CAT 50 taper, 177 station ATC, 60 HP, through-spindle and shower coolant, chip conveyor, automatic pallet changer with hydraulic clamping, rapid traverse, RENISHAW RMP60 auto gauging, ABSO scales, collision avoidance system, super-NURBS, turn cut function, cutting time (recorded at time of listing) ONLY 4524 hrs, s/n: 177346 (PURCHASED NEW IN 2018) (SOLD BY PHOTO – LOCATED IN TENNESSEE, USA)

- MAKINO (2008) MCC2013 4-axis horizontal machining center with MAKINO PROFESSIONAL 5 CNC control, 39.37”x86.75” combination table with 55” dia. rotary table, Travels: X-78.74”, Y-53.14”, Z-39.37”, B-360 deg., speeds to 15,000 RPM, HSK-A100 spindle taper, 30 station ATC, coolant through spindle, chip conveyor, MARPOSS measuring system, 400V/3PH/50-60HZ, s/n: 133 [PLANT 2]

- OKK (2006) HP500S twin-pallet CNC horizontal machining center with FANUC 180i S-MB CNC control, 19.5”x19.5” drilled and tapped pallets, Travels: X-24.75”, Y-24.40”, Z-27.95”, B-360 deg., CAT 40 spindle taper, 60 station ATC, coolant, high pressure coolant through spindle, coolant filtration, chip conveyor, 200-220V/3PH/60HZ, s/n: 268 (not in service) [PLANT 2]

- OKK (2006) HP500S twin-pallet CNC horizontal machining center with FANUC 180i S-MB CNC control, 19.5”x19.5” drilled and tapped pallets, Travels: X-24.75”, Y-24.40”, Z-27.95”, B-360 deg., CAT 40 spindle taper, 60 station ATC, coolant, high pressure coolant through spindle, coolant filtration, chip conveyor, 200-220V/3PH/60HZ, s/n: 206 (not in service) [PLANT 2]

CNC VERTICAL MILLING MACHINES

- KAFO VMM3010 CNC vertical milling machine with FANUC SERIES 15-M CNC control, 43”x112” table, Travels: X-80”, Y-40”, Z-42.75”, #50 spindle taper, speeds to 3500 RPM, coolant, chip auger, 220V/3PH/60HZ, s/n: 131066 [PLANT 2]

- TRAK DPM3 CNC vertical turret milling machine with PROTO TRAK (2016) SMX CNC control, 10”x 50” table, speeds to 3800 RPM, #40 spindle taper, pneumatic power draw bar, coolant, 220V/3PH/60HZ, s/n 073CF15712 [PLANT 2]

- TRAK DPM3 CNC vertical turret milling machine with PROTO TRAK (2007) SMX CNC control, 10”x50” table, speeds to 3800 RPM, #40 spindle taper, pneumatic power draw bar, coolant, 220V/3PH/60HZ, s/n 072CF15621 [PLANT 2]

CONVENTIONAL MACHINE TOOLS

- ECOCA (2012) SJ-2260G gap bed engine lathe with 22” swing over bed, 30” swing in the gap, 60” between centers, 12” 3 jaw chuck, 3.25” spindle bore, speeds to 1500 RPM, inch/metric threading, coolant, steady rest, 575V/3PH/60HZ, s/n: 0102103 [PLANT 2]

- COSEN (2012) SH-7550S automatic double column horizontal band saw with 28” capacity, HITECH touch screen PLC control, hydraulic vise, servo feeder, coolant, chip auger, 460V/3PH/60HZ, s/n SH10107544 [PLANT 2]

- FIRSTLC-1 1/2VSvertical turret milling machine with 9”x42” table, speeds to 4500 RPM, 2 HP, ACU-RITE 2-axis DRO, 575V/3PH/60HZ, s/n: 21127987 [PLANT 2]

- KONDIA POWERMILL TYPE FV-1 vertical turret milling machine with 9”x42” table, speeds to 4000 RPM, 3 HP, ACU-RITE 2-axis DRO, 575V/3PH/60HZ, s/n: R10 [PLANT 2]

- KONDIA POWERMILL TYPE FV-1 vertical turret milling machine with 9”x42” table, speeds to 4000 RPM, 3 HP, ACU-RITE 2-axis DRO, 575V/3PH/60HZ, s/n: Z-487 [PLANT 2]

- TOS universal milling machine with 12”x50” table, speeds to 1750 RPM, #50 spindle taper, push button pendant control, 575V/3PH/60HZ, s/n: 395 (not in service) [PLANT 2]

- HYD-MECH S-23 horizontal band saw with 20” capacity, hydraulic vise, power feed, coolant, chip auger, 600V/3PH/60HZ, s/n X0806431H [PLANT 2]

- MACC (2008) SPECIAL 400 SI 16” metal cutting horizontal band saw with miter capability, coolant, chip tray, 575V/3PH/60HZ, s/n 85268 [PLANT 2]

- MARVEL SERIES 8 tilting head sliding frame vertical band saw with 17” throat, 12” max. workpiece height, 460V/3PH/60HZ, s/n 813045 [PLANT 2]

- PROTH (2005) PSGS-3060AH hydraulic surface grinder with 12”x24” electro-magnetic chuck, 16” wheel, incremental down-feed, coolant, paper filtration, 575V/3PH/60HZ, s/n: 0508F-01 [PLANT 2]

- KENT CGS-818AHD hydraulic surface grinder with 6”x18” magnetic chuck, 8” wheel, incremental down-feed, 575V/3PH/60HZ, s/n: 86040203 [PLANT 2]

- KENT KGS-200 conventional surface grinder with 6”x18” magnetic chuck, 8” wheel, incremental down-feed, 575V/3PH/60HZ, s/n: 860251-3 [PLANT 2]

- KENT KGS-200 conventional surface grinder with 6”x18” magnetic chuck, 8” wheel, incremental down-feed, 575V/3PH/60HZ, s/n: 860451-5 (not in service) [PLANT 2]

- JAKOBSEN 1032 hydraulic surface grinder with 10”x32” magnetic chuck, 14” wheel, incremental down-feed, coolant, s/n: n/a (not in service) [PLANT 2]

- DONALDSON TORIT VS2400 5 HP floor-type dust collector, 575V/3PH/60HZ, s/n: IG524206 [PLANT 2]

- FORD-SMITH 41-P 12” heavy-duty double end pedestal grinder, 575V/3PH/60HZ, s/n: N02861 [PLANT 2]

- BALDOR A213-220 6” pedestal-type tool and cutter grinder, 575V/3PH/60HZ, s/n: n/a [PLANT 2]

- HEINMAN MACHINERY02 universal tool and cutter grinder, 110V/1PH/60HZ, s/n: 503475 [PLANT 2]

- PHOENIX universal tool and cutter grinder with collets and accessories, s/n: n/a [PLANT 2]

- TOS HOSTIVAR BN102A floor-type tool and cutter grinder, 575V/3PH/60HZ, s/n: 789 [PLANT 2]

- CONQUEST (2013) DG203 20” vertical disk sander with 15”x27” tilting table, 220V/3PH/60HZ, s/n 2030613 [PLANT 2]

- KALAMAZOO 20” abrasive cut-off saw, 575V/3PH/60HZ, s/n n/a [PLANT 2]

- MILLER DIALARC-HF portable welder with cables and gun, s/n: JG085491 [PLANT 2]

HEAT SHRINK TOOL SETTER

- HAIMER (2012) PC2006 ECONOMIC PLUS digital heat shrink-fit tool setter, 400-480V/3PH/60HZ, s/n: 7103105 [PLANT 2]

OVERHEAD BRIDGE CRANES

- ZELUS (2020) 40 ton capacity double girder top-running overhead bridge crane with approx. 68’ span, 23’ height under hook, STAHL 40 ton capacity main hoist, STAHL 20 ton capacity auxiliary hoist, continuously variable speed all directions, s/n: n/a [PLANT 2]

- KONE (2018) 30 ton capacity double girder top-running overhead bridge crane with approx. 45’ span, 17’ height under hook, KONE 30 ton capacity main hoist, KONE 5 ton capacity auxiliary hoist, continuously variable speed all directions, s/n: 58202833 [PLANT 2]

- DEMAG 14 ton capacity double girder top-running overhead bridge crane with approx. 47’ span, 20’ height under hook, DEMAG 14 ton capacity main hoist, DEMAG 10 ton capacity auxiliary hoist, 2-speed all directions, s/n: 93285 [PLANT 2]

- DEMAG 10 ton capacity double girder top-running overhead bridge crane with approx. 47’ span, 20’ height under hook, s/n: 82846 (bridge only, no hoist) [PLANT 2]

AIR COMPRESSORS

- GARDNER DENVER (2018) L55-75C 100 HP rotary screw air compressor with 20,320 hrs (recorded on meter at time of listing), 575V/3PH/60HZ, s/n: S560218 [PLANT 2]

- GARDNER DENVER RNC500A8C2N1F refrigerated air dryer with 500 SCFM @ 100 PSIG capacity, 575V/3PH/60HZ, s/n: 1000003415851 [PLANT 2]

Heavy Capacity Outdoor Forklift & Other ROLLING STOCK

- SVETRUCK (PURCHASED NEW IN 2009 FOR $600K USD) 52120 heavy duty outdoor diesel forklift with 114,000 lbs capacity, 200" max. vertical lift, 2-stage mast, side shift, fork spreader, dually with pneumatic tires, standard forks, 11,072 hrs (recorded at time of listing), s/n: 9064808

- TOYOTA 42-6FGCU30 4750 lb. capacity LPG forklift with 187” max. vertical reach, side shift, cushion tires, 18,800 hrs (recorded on meter at time of listing), s/n: 60706 [PLANT 2]

- INTERNATIONAL 9200 6X4 tandem axle semi-tractor truck with 12.6L 8 cylinder diesel engine, EATON-FULLER 13 speed manual transmission, sleeper cab, 12,000 lb. front axle, 20,000 lb. rear axles, VIN: 2HSFMAMR3WC057346 [PLANT 2]

- REITNOUER (1999) 43’tandem axle aluminum flat-deck trailer with ROLL TITE quick dra w tarp system, VIN: 1RNF43A22XR005040 [PLANT 2]

HIGH SPEED CNC VERTICAL MACHINING CENTERS

- RODERS TEC (2016) RXP500DSHZ2 high speed CNC vertical machining center with ROEDERS TEC RMS6 CNC control, 21.65”x17.71” table, Travels: X-19.68”, Y-17.91”, Z-9.44”, 13.38” max. distance spindle nose to table top, speeds to 42,000 RPM, 18.75 HP spindle drive, HSK-E40 spindle taper, 21 station ATC, 400V/3PH/60HZ, s/n: 14458-693 [PLANT 1]

- MAKINO (2004) SNC 64 high speed CNC vertical machining center with MAKINO PROFESSIONAL A CNC control, 29.52”x15.74” table, Travels: X-23.62”, Y-15.74”, Z-15.74”, HSK_A63 spindle taper, speeds to 20,000 RPM, 20/15 HP spindle motor, 15 station ATC, chip conveyor, MAKINO 1 HP cyclonic-type dust collector, MARPOSS laser tool measuring system, 200V/3PH/60HZ, s/n: SNC64 - 723 [PLANT 1]

- TAKUMI V22A CNC vertical machining center with FANUC SERIES 18-M CNC control, 94”x44” table, Travels: X–86.10”, Y–42”, Z–37.50”, 36” max. distance spindle nose to table top; speeds to 10,000 RPM, CAT 50 spindle taper, 24 station ATC, coolant, dual chip conveyors, s/n: C0179 [PLANT 1]

- TAKUMI V22A CNC vertical machining center with MITSUBISHI CNC control, 94”x44” table, Travels: X–86.10”, Y–42”, Z–37.50”, 36” max. distance spindle nose to table top; speeds to 10,000 RPM, CAT 50 spindle taper, 24 station ATC, coolant, dual chip conveyors, s/n: C0190 [PLANT 1]

- PHOENIX KAFO VTC-3010 CNC vertical machining center with FANUC SERIES 15-M CNC control, 118”x47” table, Travels: X–79”, Y–39”, Z–39”, speeds to approx. 3000 RPM, approx. 50 HP spindle drive motor, #50 spindle taper, 280V/3PH/60HZ, s/n: 131058 [PLANT 1]

CNC GANTRY TYPE VERTICAL MACHINING CENTERS

- YEONG-CHIN (2007) DCV2012B gantry type CNC vertical machining center with HEIDENHAIN iTNC530 CNC control, 78.74”x38.25” table, Travels: X-78.74”, Y- 53.15, Z-30.00”, speeds to 10,000 RPM, HSK-A100 spindle taper, 32 station ATC, coolant, chip augers, chip trays, 380V/3PH/60HZ, s/n: 10002 [PLANT 1]

- JOHNFORD (1999) DMC-3000 gantry type CNC vertical machining center with HEIDENHAIN iTNC530 CNC control, 126”x51” table, Travels: X-118”, Y- 66.37, Z-41.37”, speeds to 6000 RPM, CAT 50 spindle taper, 32 station ATC, coolant, chip augers, chip trays, 380V/3PH/60HZ, s/n: VH9033 [PLANT 1]

- REKO (retrofit 2010) GMC 1200 ram-type CNC traveling gantry type vertical machining center with HEIDENHAIN 530 CNC control, 114”x 61.5” table, Travels: X-118.20”,Y-59.94”, Z-34.98”, 91.25” between columns at table, 99” between columns above table, 57.25” under cross rail, min/max spindle to table 15”- 49.56”, CAT 50 spindle taper, speeds to 3000 RPM, 50 HP spindle motor, power draw bar, flood coolant, s/n: 9001 PB0693 (not in service – no spindle) [PLANT 1]

5-AXIS HIGH SPEED CNC FLOOR TYPE HORIZONTAL BORING MILL

- PARPAS (2005) LHS 5 axis floor-type CNC universal boring/milling machine with SELCA 4045PD CNC control, 79”x157.5” table, Travels: X-157.48”, Y–78.74”, Z–49.21”, TU600 dual rotation head: CAT 50 spindle taper, A - +/- 360 deg. @ 2.5 deg. index, C - +/- 190 deg. @ 1 deg. index, 83.46” max. horizontal distance spindle nose to table top, 78.54” max. vertical distance spindle nose to table top, speeds to 5000 RPM, TOE17 dual rotation electrospindle head: HSK-63A spindle taper, A - +/- 105 deg., C - +/- 190 deg., 90.55” max. horizontal distance spindle nose to table top, 76.37” max. vertical distance spindle nose to table top, speeds to 24,000 RPM, 15 station CAT 50 tool storage, 15 station HSK-63A tool storage, coolant, MARPOSS laser tool measuring system, s/n: LHS-18 [PLANT 1]

CNC HORIZONTAL BORING MILLS

- AWEA (2007) BL2018FM CNC horizontal boring/milling machine with FANUC SERIES 18i-MB CNC control, 6.2” spindle, 71”x63” t-slot rotary table, Travels: X-78.74”, Y–70.86”, Z–50.92”, W–23.62”, B–360 deg., CAT 50 spindle taper, speeds to 2400 RPM, 25 HP spindle motor, 40 station ATC, 17,600 lb. max. table capacity, coolant, chip conveyor, s/n: 061175 [PLANT 1]

- KURAKI (2003) KBH-22 high speed table-type CNC horizontal boring/milling machine with FANUC SERIES 16i-MB CNC control, 5” spindle, 7.87” quill dia., 78.74”x86.61” t-slot rotary table, Travels: X–118.11”, Y–90.55”, Z–62.99”, W–15.74”, 90.55” max. distance table top to spindle center, 98.43” max. distance center of table to spindle face, #50 spindle taper, speeds to 10,000 RPM, 40 HP spindle motor, 40 station ATC, 44,000 lb. max. table capacity, .001 deg. min. table index, coolant through spindle, chip conveyor, s/n: 1902 [PLANT 1]

- (2) TOS WHN 13 CNC table-type CNC horizontal boring mills with HEIDENHAIN CNC control, 5.11” spindle, 86.5”x71” t-slot rotary table, Travels: X–137.79”, Y–98.42”, Z–49.21”, W–31.49”, B-360 deg., #50 spindle taper, speeds to 2500 RPM, 50 HP spindle motor, 26,400 lb. max. table capacity, coolant, s/n: n/a, n/a [PLANT 1]

- KURAKI KBT-13-A table-type CNC horizontal boring/milling machine with FANUC SERIES 16-M CNC control, 5.12” spindle, 62.99”x70.87 t-slot rotary table, Travels: X–118.11”, Y–90.55”, Z-51.18”, W–27.56”, B-360 deg., 90.55” max. distance table top to spindle center, 78.74” max. distance center of table to spindle face, #50 spindle taper, speeds to 2500 RPM, 40 HP spindle motor, 60 station ATC, 26,400 lb. max. table capacity, .001 deg. min. table index, coolant, chip conveyor, s/n: 8036 (spindle removed for service) [PLANT 1]

- TOS WHN-13-4-A table-type horizontal boring mill with 5” spindle, 63”x70.5” t-slot rotary table, Travels: X–78”, Y–78”, W–49”, B-360 deg., CAT 50 spindle taper, speeds to 900 RPM, 50 HP spindle motor, 26,400 lb. max. table capacity, coolant, chip conveyor, HEIDENHAIN DRO, s/n: 0801 [PLANT 1]

4-AXIS CNC GUN DRILLS

- TPI TARUS (2007) TPTCGD512SB 4 axis CNC dual spindle table-type gun drill with LEMOINE CNC control, 60”x144” table, Travels: X (table travel)–156”, Y (column travel)–25”, Z (vertical travel)-60”, W (spindle travel)-92”, 5” spindle, CAT 50 taper milling head, coolant through spindle, chip conveyor, 22,000 hrs (recorded on meter at time of listing), s/n: TPTCGD2574074410 [PLANT 1]

- TPI TARUS TPTCGD512 4 axis CNC dual spindle table-type gun drill with LEMOINE CNC control, 60”x144” table, Travels: X (table travel)–156”, Y (column travel)–25”, Z (vertical travel)–62””, W (spindle travel)–86”, main spindle speeds to 3400 RPM, auxiliary spindle speeds to 2000 RPM, 5” spindle, CAT 50 taper milling head, coolant through spindle, chip conveyor, s/n: TPTCGD1933053 [PLANT 1]

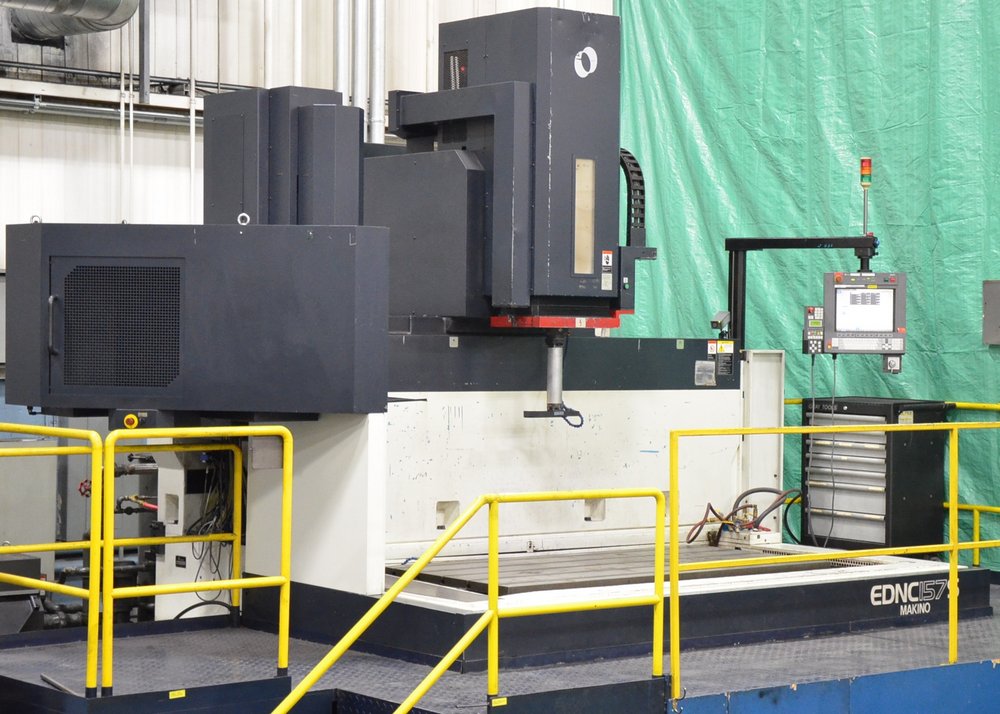

CNC RAM TYPE EDMS

- MAKINO (2012) EDNC 157 CNC ram type sinker EDM with MAKINO MGH6 CNC control, 98.42”x55.11”x31.49” tank, 39.37”x78.74” table, Travels: X-59.05, Y-27.55”, Z-19.68”, 300A power supply, SYSTEM 3R head, 16 station ATC, dielectric fluid tank with pumps and filtration, HALON automatic fire suppression system, 208V/3PH/60HZ, s/n: 106 [PLANT 1]

- MAKINO (2008) EDNC 157S CNC ram type sinker EDM with MAKINO MGH5 CNC control, 98.42”x55.11”x31.49” tank, 39.37”x78.74” table, Travels: X-59.05, Y-27.55”, Z-19.68”, 300A power supply, SYSTEM 3R head, 16 station ATC, dielectric fluid tank with pumps and filtration, HALON automatic fire suppression system, 208V/3PH/60HZ, s/n: 85 [PLANT 1]

- ZAP (2013) CNC-400A CNC ram type sinker EDM with ADVANTAGE SERIES CNC EDM WINDOWS PC based touch screen control, 62”x42”x23” tank, 23.5”x39.25” table, 300A power supply, SYSTEM 3R C-axis head, HIRSCHMANN ATC, dielectric fluid tank with pumps and filtration, HALON automatic fire suppression system, 230V/3PH/60HZ, s/n: 13-129 [PLANT 1]

- EDM SOLUTIONS (2001) DISCOVERY CNC-416 ram type sinker EDM with HEIDENHAIN TNC 416 CNC control, 120”x65”x25” tank, 30.75”x99” table, 300A power supply, SYSTEM 3R C-axis head, HIRSCHMANN ATC, dielectric fluid tank with pumps and filtration, HALON automatic fire suppression system, 600V/3PH/60HZ, s/n: 91111 [PLANT 1]

- ONA PD-6.120-S1 CNC gantry type sinker EDM with DATIC S120 CNC control, 130”x60”x34” tank, 46.50”x96.50” table, 24” vertical stroke, power supply, SYSTEM 3R C-axis head, dielectric fluid tank with pumps and filtration, HALON automatic fire suppression system, 380V/3PH/60HZ, s/n: 7872/9711 [PLANT 1]

- MAKINO (2012) EDAF3 CNC sinker type EDM with MAKINO MGH6 CNC control, 27.5” x 19.5” table size, travels: X – 17.5”, Y – 13.5”, Z – 13.5”, work tank dimensions 33” x 26” x 18” H, 16 station ATC, SYSTEM 3R C-axis, dielectric tank and filtration, 208v/3ph/60hz, s/n: E80225 [PLANT 1]

CNC WIRE TYPE EDMS

- MAKINO (2008) SP64 CNC wire EDM with MAKINO MGW-S5 CNC control, 44”x35”x20” tank, wire spool feeder, handheld MPG pendant control, dielectric fluid tank with pumps and filtration, HALON automatic fire suppression system, 400V/PH/50HZ, s/n: W8172 [PLANT 1]

- MAKINO (2003) SP43 CNC wire EDM with MAKINO MGW-R CNC control, 35”x32”x18” tank, wire spool feeder, handheld MPG pendant control, dielectric fluid tank with pumps and filtration, HALON automatic fire suppression system, 400V/3PH/50HZ, s/n: W7056 [PLANT 1]

CONVENTIONAL MACHINE TOOLS

- HWACHEON (2008) HRD-2000 7’ radial arm drill with 38” column, speeds to 2080 RPM, 25.5”x31.5”x22”H t-slot box table, s/n: R20157 [PLANT 1]

- (2) GENTIGER (2008) SHCM-S96RA vertical turret milling machines with 49”x11” table, speeds to 3600 RPM, RESSON RD-12S 3 axis DRO, power table, coolant, 575V/3PH/60HZ, s/n: 97571, 97570 [PLANT 1]

- FIRST LC185VS vertical turret milling machine with 50”x10” table, speeds to 4500 RPM, HEIDENHAIN DRO, 3 HP, 575V/3PH/60HZ, s/n: 30705291 [PLANT 1]

- FIRST 1F-1-1/2 VS vertical turret milling machine with 42”x9” table, speeds to 4500 RPM, ACU-RITE DRO, 575V/3PH/60HZ, s/n: 070740 [PLANT 1]

- FIRST LC-1 ½ VS vertical turret milling machine with 42”x9” table, speeds to 4500 RPM, ACU-RITE DRO, 575V/3PH/60HZ, s/n: 10517134 [PLANT 1]

- KONDIA POWERMILL TYPE FV-1 vertical turret milling machine with 48”x12” table, speeds to 4000 RPM, ACU-RITE 2 axis DRO, 575V/3PH/60HZ, s/n: V-933 [PLANT 1]

- TOS SN40B engine lathe with 16” swing over bed, 42” between centers, 2” spindle bore, speeds to 2000 RPM, inch/metric threading, 10” 3 jaw chuck, s/n: 040100850771 [PLANT 1]

- MARVEL SERIES 8 MARK I tilting head sliding frame vertical band saw with 17” throat, 12” max. workpiece height, 230V/3PH/60HZ, s/n: 824015-W [PLANT 1]

- BAXTER VERTICUT 360-SA horizontal band saw with 20”x15.5” capacity, 2 HP, coolant, 575V/3PH/60HZ, s/n: 4162 [PLANT 1]

- CHEVALIER hydraulic surface grinder with 12”X24” magnetic chuck, 12” wheel, incremental down feed, coolant, coolant filter system, 575V/3PH/60HZ, s/n: P3891004 [PLANT 1]

- PROTH hydraulic surface grinder with 12”x24” magnetic chuck, 12” wheel, incremental down feed, coolant, coolant filter system, 575V,3PH,60HZ, s/n: n/a [PLANT 1]

- (3) CHEVALIER FSG-618M conventional surface grinders with 6” x 18” magnetic chuck, 8” wheel, incremental down feed, 575v/3ph/60hz, s/n A3921018, A389A043, A386A065 [PLANT 1]

- (2) JIN YOUNG (2008) JFG-520M conventional surface grinders with 8”x18” magnetic chuck, 8” wheel, incremental down feed, SONY 2 axis DRO, 208V/3PH/60HZ, s/n: 08F00052, 08F00051 [PLANT 1]

- ACER SUPRA-618 conventional surface grinder with 6” x 18” magnetic chuck, 8” wheel, incremental down feed, 230-460v/3ph/60hz, s/n n/a [PLANT 1]

- SUNNEX 50 ton capacity H-frame shop press, s/n: n/a [PLANT 1]

- WILTON 20” dia. disc sander, s/n: n/a [PLANT 1]

- HAMMOND MD-12 10” double end pedestal grinder with 175 RPM, 2 HP, s/n: 3299 [PLANT 1]

- KALAMAZOO 14” abrasive cut off saw with 5 HP, dust collector, s/n: n/a [PLANT 1]

- (3) DECKEL SO bench-type tool cutter/grinders s/n: 90-24479, 00-27069 [PLANT 1]

- (2) FLEXARM extendable tapping arms with INGERSOLL RAND 7667-2K pneumatic unit [PLANT 1]

WELDING EQUIPMENT

- VISION 150 FASTWELD GMBH digital laser welding machine with 18.5”x16” table, 150W class 4 laser, 400V/60HZ, s/n: LWI IV-06.09-0408-02 [PLANT 1]

- LINCOLN ELECTRIC PRECISION TIG 275 portable digital TIG welder with cables and gun, s/n: U1120609755 [PLANT 1]

- LINCOLN ELECTRIC PRECISION TIG 225 portable digital TIG welder with cables and gun, s/n: n/a [PLANT 1]

- MILLER SYNCROWAVE 200portable digital TIG welder with cables and gun, s/n: n/a [PLANT 1]

- MILLER SYNCROWAVE 250 DX portable digital TIG welder with MILLER COOLMATE 4 chiller, cables and gun, s/n: LB271702 [PLANT 1]

HEAT SHRINK TOOL SETTER

- HAIMER (2012) POWERCLAMP 2006 digital heat shrink-fit tool setter with 480V/60HZ, s/n: 7103100 [PLANT 1]

OVERHEAD CRANES

- CANADIAN CRANE 50 ton capacity double girder top running overhead bridge crane with 56’ span, 22’ height under hook, KULI 50 ton capacity main hoist, KULI 20 ton capacity auxiliary hoist, single speed North/South, 2-speed all other directions, s/n: 10173-1 [PLANT 1]

- CANADIAN CRANE 30 ton capacity double girder top running overhead bridge crane with 56’ span, 24’ height under hook, KULI 30 ton capacity main hoist, KONE CRANE 1.5 ton capacity auxiliary hoist, 2-speed all directions, s/n: 10173-2 [PLANT 1]

- DEMAG 30 ton capacity double girder top running overhead bridge crane with 56’ span, 24’ height under hook, DEMAG 30 ton capacity main hoist, DEMAG 14 ton capacity auxiliary hoist, 2-speed all directions, s/n: 03411 [PLANT 1]

- STAHLKRAN INC. 30 ton capacity double girder top running overhead bridge crane with 52’ span, 24’ height under hook, CANADIAN CRANE 30 ton capacity hoist, 2-speed all directions, s/n: n/a [PLANT 1]

SPOTTING & TRYOUT PRESSES

- USI CLEARING PS4-300-156-100, 300 ton capacity single action straight side tryout press with 100” x 156” front to back roll in bolster, 60” stroke, 49” shut height, 40” x 55” side windows, s/n 11-5203 [PLANT 1]

- NEWMAN WHITNEY HP-190 345 ton capacity 4 post hydraulic spotting press with 96”x96” front to back roll in bolster, 96”x96” platen, 72” stroke, 39” shut height, s/n: 14892 [PLANT 1]

- EAGLE PRESS PH2-200-78-84 200 ton capacity 4 post hydraulic spotting press with 78”x84” front to back roll in bolster, 84”x104” platen, 48” stroke, 32” shut height, 80” daylight, s/n: EP-126-032696 [PLANT 1]

- NAM YANG (2008) NDS-250 250 ton capacity hydraulic die spotting press with 78”x98” front to back roll in bolster, 78”x98” hydraulic tilting platen, 78” stroke, 78” open height, PRO-FACE touchscreen PLC control, s/n: 1428 [PLANT 1]

- MILLUTENSIL MIL162 150 ton capacity hydraulic spotting press with 49”x63” front to back roll in bolster, 51”x63” hydraulic titling platen, 39” stroke, 16” shut height, s/n: 733-16211 [PLANT 1]

- USI ARTCO H4C 10-51X36 10 ton capacity hydraulic 4 post press with 36”x51” bolster, 36”x51” platen, 20” stroke, 24” shut height, 41” daylight, s/n: 70402101 [PLANT 1]

AIR COMPRESSORS

- ATLAS COPCO (2012) GA55 75 hp rotary screw-type air compressor with approx. 52,500 hours (recorded on meter at time of listing), 575v/3ph/60hz, s/n: API615086 [PLANT 1]

- ATLAS COPCO (2006) 56VSD 75 hp rotary screw-type air compressor with approx. 102,550 hours (recorded on meter at time of listing), 575v/3ph/60hz, s/n: API572008 [PLANT 1]

- ATLAS COPCO (2003) GA37 50 hp rotary screw-type air compressor with approx. 91,175 hours (recorded on meter at time of listing), 575v/3ph/60hz, s/n: AII383134 [PLANT 1]

FACTORY SUPPORT EQUIPMENT

- CLARKE BOOST walk-behind electric floor scrubber [PLANT 1]

- TRINCO 60X24SL/BP DRY BLAST dual station shot blast cabinet with dust collector, 120V/1PH/60HZ, s/n: 64886-7 [PLANT 1]

- DONALDSON TORIT DOWNFLO DF T2-8 15 HP cartridge-type dust collector with 3450 RPM, 575V/3PH, s/n: TG566995-001 [PLANT 1]

- DONALDSON TORIT DOWNFLO DF T2-8 10 HP cartridge-type dust collector with 3450 RPM, 575V/3PH, s/n: TG445634-001 [PLANT 1]

- DONALDSON TORIT DOWNFLO OVAL DF02-4 approx. 5 HP cartridge-type dust collector, s/n: 11395467-L1-1 [PLANT 1]

- PETS SSMC2-24 24 zone controller with 575V/3PH, transformer, s/n: 2004RD [PLANT 1]

- ITC MF12-150-V3 12 zone controller with 240V/3PH, transformer, s/n: 20039-11/0 [PLANT 1]

COORDINATE MEASURING DEPARTMENT

- ZEISS DB1200 co-ordinate measuring machine with 90”x134”x26” drilled and tapped granite table, travels X–120”, Y–60”, Z-42”, ZEISS RDS touch probe, ZEISS BP26_SE digital joystick control, PC, s/n: CMM980804405 [PLANT 1]

- BROWN & SHARPE VALIDATOR co-ordinate measuring machine with 51”x72”x8” drilled and tapped granite surface table, travels X–48”, Y-33”, Z-24”, RENISHAW PH10M touch probe, METROLOGIC ME470 digital joystick control, PC, s/n: 0332-142 [PLANT 1]

- 120”x60”x12” granite surface plate with stands [PLANT 1]

ANGLE PLATES & TOMBSTONES

- Set of (2) 84”x22” FCS system angle plates [PLANT 1]

- Set of (2) 72”x36” FCS system angle plates [PLANT 1]

- Set of (2) 75.5”x32” t-slot angle plates [PLANT 1]

- Set of (2) 74.5”x39.5” t-slot angle plates [PLANT 1]

- Set of (2) 66”x30” t-slot angle plates [PLANT 1]

- 55”x59” FCS system angle plate [PLANT 1]

- 59”x86.5” angle plate [PLANT 1]

- 70”x74”x73”H FCS system double sided tombstone [PLANT 1]

- (2) 36”x73”x46”H FCS system box tables [PLANT 1]

FORKLIFTS & ROLLING STOCK

- TOYOTA 7FGCU35 7150 lb. capacity LPG forklift with 187” max. lift height, 3 stage mast, side shift, fork spreader, solid tires, 12,080 hrs (recorded on meter at time of listing), s/n: 63806 [PLANT 1]

- TOYOTA 7BWS13 24V 2500 lb. capacity walk-behind electric pallet stacker with 143” max. lift height, s/n: 7BWS13-42474 [PLANT 1]

- MACK (2007) GU813 straight truck with 12.7L 6 cylinder diesel engine, EATON FULLER 18 speed manual transmission, 24’ flatdeck with rolling tarp, power locks, power windows, CD player, AM/FM radio, A/C, 353,063 KM (recorded on meter at time of listing), VIN: 1M2AX16C08M001348 [PLANT 1]

- INTERNATIONAL (2004) DURASTAR 4200 straight truck with 6.9L 6 cylinder diesel engine, ALLISON automatic transmission, 18’ flatdeck with rolling tarp, manual locks, manual windows, A/C, CB radio, 705,227 KM (recorded on meter at time of listing), VIN: 1HTMPAFP25H112673 [PLANT 1]

- TITAN TRAILER MODEL 189 6 axle 48’ flat bed trailer with removable sides and tarp, VIN: 2K9PF1L67TH035032 [PLANT 1]

- TRAILERMOBILE F71T-6RAG tandem axle 45’ flat bed trailer with rolling tarp, VIN: 1PTF7ATAXR9014778 [PLANT 1]

- FORD (2011) F250 SUPER DUTY pickup truck with 6.2L 8 cylinder gas engine, automatic transmission, RWD, manual locks, manual windows, AM/FM radio, A/C, 287,546 KM (recorded on meter at time of listing), VIN: 1FTBF2A63BEC65460 [PLANT 1]

- FORD (2008) F150 XL TRITON pickup truck with 4.6L 8 cylinder gas engine, automatic transmission, RWD, manual locks, manual windows, AM/FM radio, A/C, 334,698 KM (recorded on meter at time of listing), VIN: 1FTRF12W18KF01167 [PLANT 1]

- PONTIAC (2008) G8 GT 4 door sedan with 6.0L V8 gas engine, automatic transmission, power locks, power windows, leather seats, sunroof, alloy rims, CD player, AM/FM radio, A/C, 285,242 KM (recorded on meter at time of listing), VIN: 6G2EC57Y39L167493 [PLANT 1]

- PONTIAC (2008) G5 4 door sedan with 2.2L 4 cylinder gas engine, manual transmission, power locks, power windows, alloy rims, CD player, AM/FM radio, A/C, 172,767 KM (recorded on meter at time of listing), VIN: 1G2AS55H497114554TT [PLANT 1]

ALSO FEATURING FROM BOTH PLANTS

(20+) LISTA multi-drawer tool cabinets; MASSIVE HIGH END OFFERING of FCS CLAMPING SYSTEM components - RINGS, RODS, CUBES, BEAMS, THIRD SUPPORT POINTS, (100+) PALLETS & MORE!; (50+) KURT machine vises; HUGE INVENTORY of HSK, CAT 50, CAT 40 tool holders; SYSTEM 3R EDM tooling; LARGE selection of LIFTING SUPPLIES consisting of swivel eyebolts, lifting chains, lifting slings, wire slings, lifting magnets; power tools; air tools; hand tools; (100+) work benches; INSPECTION EQUIPMENT including digital height gauges, vernier calipers, outside micrometers, inside micrometers, depth gauges; angle plates; box tables; risers; self-dumping hoppers; VAST ASSORTMENT of PERISHABLE TOOLING – drills, reamers, end mills, taps, dies, carbide & HSS tools; tie-down clamping; transformers; set-up blocks; tool boxes; sanding & grinding perishables; pallet trucks; hydraulic power packs; SPARE PARTS including, but not limited to HYDRAULIC & PNEUMATIC fittings, hoses and lines. HYDRAULIC CYLINDERS, spare motors, hardware; FASTENAL pigeon hole cabinets & hardware storage drawers; hydraulic power packs; shop fans; shop vacs; shop carts; JUSTRITE fireproof storage cabinets; toolboxes; shop supplies; computers; business machines; late model office furniture and MUCH MORE!