Nexxa Industries Ltd.

Late Model & High Precision CNC Machining Facility

Date

Tuesday, March 28, 2023

Start Time

10:30 AM MDT

Inspection

Monday, March 27 from 8 AM to 3:30 PM or by appointment. Please email info@corpassets.com to arrange.

Removal

All assets must be removed no later than Tuesday, April 18 by appointment only.

Industry

FEATURING: DOOSAN (2020, commissioned in 2021) PUMA GT3100 CNC turning center (LIKE NEW); HYUNDAI WIA (2014, commissioned in 2015) F500 5-axis vertical machining center; OMAX (2007) 55100 CNC waterjet cutting system ; NAKAMURA-TOME (2003) SC-300 CNC turning center; CINCINNATI HAWK 150 A2100 CNC turning center; MATSUURA (2001) MC-800VG2 vertical machining center; MATSUURA (2001) RA-2G twin-pallet vertical machining center; MATSUURA RA-3G2 twin-pallet vertical machining center; KASTO (2004) KASTO A 2 CNC horizontal bandsaw; HYD-MECH (2003) S-20 horizontal bandsaw; MODERN 22-80 gap bed engine lathe; TIMESAVERS 125 IMW 25” automatic belt sander; FS CURTIS FNB11B8X3JXXX 15 HP air compressor; FRUILAIR (2011) ACT75U-1 air dryer; (3) BURR KING VIBRA KING 25 vibratory finishing machine; MITSUBISHI (REFURBISHED 2007) 2FBC15 36V electric forklift with 3,000 LB capacity; ALSO FEATURING: BT 40 tool holders, tool cabinets with perishable tooling, machine vises, rotary table, angle plates and indexing heads, selection of inspection equipment, non-ferrous and ferrous raw materials, MRO spare parts & MORE!

Rigging and Removal Details

THE EXCLUSIVE RIGGER FOR THIS SALE IS:

WINGENBACK LTD.

RYAN POTTER

OFFICE: 403-221-8211 | CELL- 403-888-1144

RYANP@WINGENBACK.COM

*All assets must be removed no later than Tuesday, April 18. For everyone’s safety removal at this site is conducted strictly by appointment only. All machinery buyers must contact Ryan Potter - ryanp@wingenback.com to set their pick-up appointments upon payment in full.

*Further information on removal details can be found in the Terms & Conditions tab or in the Lot Catalogue.

TRUCKING AND TRANSPORT SERVICES:

Trucking and transport services, including cross-border logistics, are available through Fuze Logistics Inc. Please contact Chris Tan for a firm quote or any questions regarding transportation.

Fuze Logistics Services Inc.

Chris Tan

514.799.4162

machinerylogistics@fuzelogistics.com

CNC TURNING CENTERS

- DOOSAN (2020, commissioned in 2021) PUMA GT3100 CNC turning center with DOOSAN EOP CNC control, 28.35” swing over bed, 18.94” max. turning diameter, 29.72” max. turning length, travels: X-10.24”, Z-32.68”, 4.53” spindle bore, 10-station turret, speeds to 2,800 RPM, 29 HP spindle motor, SAMCHULLY MH-212 12” 3-jaw chuck, coolant, chip conveyor, hydraulic tailstock, tool checker arm, LNS (2021) CHIPBLASTER D30-35 chip blaster (may be sold separately), s/n ML0311-000392

- NAKAMURA-TOME (2003) SC-300 CNC turning center with FANUC 21-T CNC control, 22.04” max. swing over bed, 13.77” max. turning diameter, 23.62” max. turning length, travels: X-8.75”, Z-25”, 3.34” spindle bore, 12-station turret, speeds to 3,500 RPM, 29.91 HP spindle motor, KITAGAWA B- 212 12” 3-jaw chuck, coolant, chip conveyor, hydraulic tailstock, tool checker arm, s/n S308105

- CINCINNATI (2000) HAWK 150 A2100 CNC turning center with ACRAMATIC 2100 CNC control, 20.47” max. swing over bed, 9.45” max. turning diameter, 17.32” max. turning length, travels: X-8.46”, Z-17.32”, 2.01” spindle bore, 12-station turret, speeds to 5,500 RPM, 7.5 HP spindle motor, 7” 3-jaw chuck, coolant, chip conveyor, hydraulic tailstock, s/n 7051 A00 990446

5-AXIS CNC VERTICAL MACHINING CENTER

- HYUNDAI WIA (2014, commissioned in 2015) F500 5-axis vertical machining center with FANUC I SERIES CNC control, 47.2” x 19.7” table, travels: X-31.5”, Y-18.1”, Z-20.5”, A-180 DEG in 0.01 DEG increments, B-90 DEG in 0.01 DEG increments, 30.9” maximum distance spindle nose to tabletop, spindle speeds to 10,000 RPM, BT 40 taper, 24-station ATC, RENISHAW OTS tool setter, through spindle coolant, chip conveyor, s/n G3684-1422

4-AXIS CNC VERTICAL MACHINING CENTER

- MATSUURA (2001) MC-800VG2 vertical machining center with YASNAC CNC control, 45.27” x 20.07” table, travels: X-31.5”, Y-20.07”, Z-19.68”, A-180 DEG in 0.01 increments, 25.59” maximum distance spindle nose to tabletop, spindle speeds to 12,000 RPM, BT 40 taper, 30-station ATC, through spindle coolant, chip conveyor, 200-220v/3ph/50-60hz, s/n 010314675 (4th axis may be sold separately)

TWIN-PALLET CNC VERTICAL MACHINING CENTERS

- MATSUURA (2001) RA-2G twin-pallet vertical machining center with YASNAC CNC control, (2) 28.3” x 17.3” pallets, travels: X-26”, Y-18.11”, Z-19.09”, 25” maximum distance spindle nose to tabletop, spindle speeds to 15,000 RPM, BT 40 taper, 30-station ATC, coolant, chip conveyor, 200-220v/3ph/50-60hz, s/n 010214544

- MATSUURA (2000) RA-3G2 twin-pallet vertical machining center with YASNAC CNC control, (2) 31.5” x 19.3” pallets, travels: X-31.5”, Y-20.08”, Z-19.69”, 25.59” maximum distance spindle nose to tabletop, spindle speeds to 12,000 RPM, BT 40 taper, 30-station ATC, coolant, chip conveyor, 200-220v/3ph/50-60hz, s/n 000914369 (not in service)

CNC WATERJET CUTTING SYSTEM

- OMAX (2007) 55100 CNC waterjet cutting system with OMAX WINDOWS PC based CNC control, 55” x 100” table, travels: X-97”, Y-52.6”, Z-6”, bevelling head with 9 DEG tilt, OMAX P4055V intensifier pump (rebuilt 05/2020), closed loop filtration system, media recovery system, 460v/3ph/60hz, s/n B512083

CNC HORIZONTAL BANDSAW

- KASTO (2004) KASTO A 2 CNC horizontal bandsaw with KASTO COMPACT CNC control, 10.25” x 10.25” cutting capacity, 30” stroke hydraulic feed saddle, bundle cutting, 178.35” x 1.34” x 0.04” blade, coolant, chip conveyor, 108” in feed conveyor, 440v/3ph/60hz, s/n 6459 102 012

CONVENTIONAL MACHINE TOOLS

- MODERN 22-80 gap bed engine lathe with 22” swing over bed, 31-3/8” swing over gap, 80” between centers, 4-1/16” spindle bore, speeds to 1,200 RPM, 16” 3-jaw chuck, in/mm threading, steady rest, ACU RITE 2-axis DRO, 208v/3ph/60hz, s/n 01009

- HYD-MECH (2003) S-20 horizontal bandsaw with 2 HP motor, manual bundling, coolant, 208v/3ph/60hz, s/n 61000308

- TIMESAVERS 125 IMW 25” automatic belt sander, 230v/3ph/60hz, s/n 19152

- DOUCET PMC-202 stroke belt sander with 28” x 71.5” table, 6” x 202” sanding belt, 3 HP motor, PIONEER PNR 12-100 dust collector unit, s/n 7006-09-211

- REXON RDM-100F 14” drill press with 12” DIA table, 5/8” capacity, s/n N/A

- ADVANCE drill press with ½ HP motor, s/n N/A

- (2) MFG UNKNOWN arbor presses with 5.25” throat, s/n N/A

FACTORY SUPPORT EQUIPMENT

- FS CURTIS FNB11B8X3JXXX 15 HP air compressor with 125 PSI, 230v/3ph/60hz, s/n NB11F18071

- FRUILAIR (2011) ACT75U-1 air dryer with 200 PSIG max. air pressure, 115v/1ph/60hz, s/n 110003074

- TAL INTERNATIONAL (2010) 1CC-03FE20C-02G 20’ sea container, s/n TCCC10A 007237

- (3) BURR KING VIBRA KING 25 vibratory finishing machines, s/n BK-21565; BK-21566; BK-21567

ROLLING STOCK

- MITSUBISHI (REFURBISHED 2007) 2FBC15 36V electric forklift with 3,000 LB capacity, 188” maximum vertical reach, side-shift, cushion tires, 5,132 hours (recorded on meter at time of listing), ENERGIC PLUS TSS-D 36/120 36V battery charger (may be sold separately), s/n A2BC1-21051

ALSO:

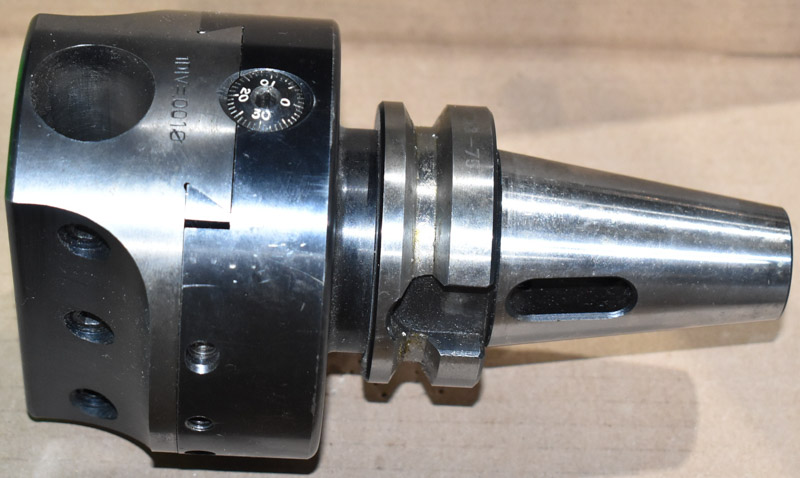

- LARGE SELECTION OF BT 40 tool holders; tool cabinets with perishable tooling including drill, endmills, reamers, taps, carbine insert cutters, carbide insert boring bars, carbide inserts; machine tool accessories consisting of machine vises, rotary table, angle plates and indexing heads; hand tools, power tools and pneumatic tools; tool boxes; selection of inspection equipment, non-ferrous and ferrous raw materials including bar, tube and flat stock; MRO spare parts & MUCH MORE!