Surplus Assets of

Harris Wood Facility

200,000+ Sq. Ft. Wood Flooring Manufacturing Facility

Date

Thursday, September 28, 2023

Start Time

9:30 AM EDT

Inspection

Wednesday, September 27 from 8 AM to 4 PM.

Removal

All assets must be removed no later than Tuesday, October 31 by appointment only. Rigging details to follow.

Industry

FEATURING: BURKLE automatic panel press line; ROSENQUIST conventional panel press line; HARRIS WOOD custom finishing line; HARRIS fully automatic board milling line; (2) Roll Coating/UV Curing Finishing Lines; HARRIS WOOD PFL-2 packaging line; Scrap Wood Handling System; PNEUMAFIL plant dust collection system; HUGE OFFERING OF: CNC & Conventional wood working machinery, numerous maintenance and machine shop departments, (65+) Sections of adjustable pallet racking, MROs & SPARE PARTS, transformers up to 112.5 KVA, (2) biomass boilers with gas backup, inspection equipment, HUGE QUANTITY of WIP flooring boards including HICKORY, OAK, MAPLE, WHITE OAK, RED OAK, RED MAPLE, bearing inventory, electrical parts and components, ferrous and nonferrous raw materials inventory, sealed drums of wood stain & MUCH MORE!

Rigging and Removal Details

FOR SMALL ITEMS NOT REQUIRING RIGGING, PLEASE CONTACT:

Adam Michelini | 416 917 2025 | amichelini@corpassets.com

THE EXCLUSIVE MACHINERY AND EQUIPMENT RIGGER FOR THIS SALE IS:

Gorham Industrial LLC

James Gorham | 803 617 8434 | jgorhamindustrial@hotmail.com

*All assets must be removed no later than Tuesday, October 31. For everyone’s safety removal at this site is conducted strictly by appointment only. All buyers must contact amichelini@corpassets.com to coordinate pick-up appointments upon payment in full.

*Further information on removal details can be found in the Terms & Conditions tab or in the Lot Catalogue.

TRUCKING AND TRANSPORT SERVICES:

Trucking and transport services, including cross-border logistics, are available through Fuze Logistics Inc. Please contact Chris Tan for a firm quote or any questions regarding transportation.

Fuze Logistics Services Inc.

Chris Tan

941-702-3310

machinerylogistics@fuzelogistics.com

AUTOMATIC PANEL PRESS LINE

BURKLE (2002) automatic panel press line with SIEMENS SIMATIC PLC control, steam-fired hot oil double stack hydraulic platen press with 20 min total cycle time, 4’x4’ & 4’x8’ panel capacity, 215-250 deg. F. operating temperature range, consisting of:

- (5) BURKLE SL-RB 52”x125” variable speed powered horizontal roller conveyors, s/n: 10029009, 10029016, 10029015, 10039035, 10039034

- (3) BURKLE PSG-T1-J bridge-type pick & place vacuum transfer systems with 60” horizontal stroke, approx. 52”x92” max. panel size, s/n: 10029017, 10029021, 10029033

- (3) BURKLE TYPE RF approx. 78”x90” variable speed horizontal powered belt conveyors, s/n: 10029019, 10029018, 10029020

- BURKLE DAK 1400 55” roll coater adhesive applicator, s/n: 10029-05

- MFG. UNKNOWN 2-part adhesive mixing & dispensing station with 1000L/265 gal. capacity IBC tote stand & load cells, ARO pneumatic diaphragm pump, digital flow meter, catalyst injection nozzle, s/n: n/a

- HALDEX HYDRAULICS 48”x94” rolling hydraulic scissor lift platform with 56”x51” horizontal roller conveyor, s/n: n/a

- (2) HYTROL 48”x120” variable speed powered horizontal roller conveyors with AUTOQUIP 4000 lb. capacity hydraulic scissor lift table, s/n: 490687, 490682

- BURKLE PSG-T1 bridge-type pick & place vacuum transfer system with approx. 120” horizontal stroke, approx. 48”x96” max. panel size, s/n: 10029003

- (5) BURKLE TYPE RB 52”x125” variable speed powered horizontal roller conveyors, s/n: 10029010, 10029011, 10029030, n/a, 10029032

- (5) BURKLE 54”x124” variable speed powered horizontal belt conveyors, s/n: n/a

- BURKLE OPTIMA-2x6E steam-fired hot oil double stack hydraulic platen press with 20 min total cycle time, 4’x4’ & 4’x8’ panel capacity, 215-250 deg. F. operating temperature range (in current configuration), (6) 56”x124” upper & (6) 56”x124” lower independently operated platens, (2) 6-position chain-driven elevating feed/discharge towers, 50 HP hydraulic power pack, control cabinet, WILD AUTOMATION PLC control, s/n: 10023027

- HEIZA 2XSKHWTO steam/oil heat exchange system, s/n: 8181B

- GRECON UPU2000-8 on-line continuous bond analyzer, s/n: 124

- BURKLE SL-RB 52”x120” variable speed powered horizonal roller conveyor with forklift slots, s/n: 10039036

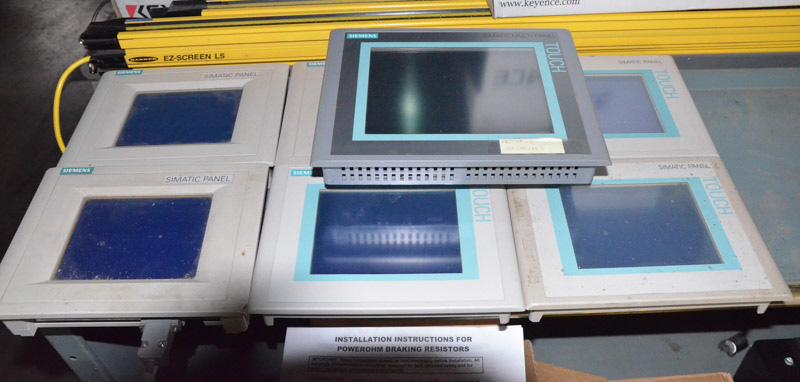

- BURKLE SYSTEMWILD press line controls & automation with SIEMENS SIMATIC PLC controls, laser sensors, safety light curtains & interlock safety cages, s/n: n/a

CONVENTIONAL PANEL PRESS LINE

ROSENQUIST conventional panel press line consisting of:

- ARROW AUTOMATION 2-part adhesive mixing & dispensing station with 1000L/265 gal. capacity IBC tote stand & load cells, ARO pneumatic diaphragm pump, digital flow meter, catalyst injection nozzle, SIEMENS SIMATIC PLC touch screen control, s/n: n/a

- HYTROL 51”x44” 4000 lb. capacity hydraulic scissor lift, s/n: n/a

- HYTROL 51”X96” powered horizontal roller conveyor, s/n: n/a

- (3) MFG. UNKNOWN 55” roll-feed adhesive applicators, s/n: n/a

- 4’x68’ powered roller conveyor with (4) cross chain belt diverters

- (3) ROSENQUIST 10-platen direct steam-fired hydraulic platen presses with 48”x60” platens, manual load/unload tower, digital microprocessor control, safety light curtains, s/n: n/a

- HYTROL 32”x52’ powered horizontal belt conveyor, s/n: n/a

- AUTOMATION INDUSTRIES CORP. controls with laser sensors, s/n: n/a

CUSTOM SCRAPE FINISHING LINE

HARRIS WOOD custom finishing line consisting of:

- (2) 45”x92” horizontal travelling infeed belt conveyors, s/n: n/a

- MFG. UNKNOWN board diverter/positioner with 2” stroke, pneumatic lift, left-hand & right-hand controls, s/n: n/a

- PF L2-3502 52”x 16’ powered horizontal roller conveyor, s/n: n/a

- COSTA 80 C 1350 52” single head wide belt sander with 54 HP, s/n: CL 90 415

- MFG. UNKNOWN 48”x110” powered horizontal belt conveyor with (6) FOSTORIA FSS-3148-1 SUN-MITE 3000 watt capacity overhead infrared heating lamps, s/n: n/a

- MFG. UNKNOWN 48” panel coating roll, s/n: n/a

- (2) 52”x174” powered horizontal belt conveyors

- COSTA (2013) K7 TTFF 1350 4-head scrape finisher with SCHINDER ELECTRIC MAGELIS touch screen control, (2) 54.33” 33.5 HP belt sanding/scraping heads, (2) 54.33” 7 HP wire brush heads, industrial chiller, blow off, s/n: LB131022A

- HYTROL 48”x120” powered horizontal roller conveyor with AUTOQUIP 2500 lb. capacity scissor lift table, s/n: 490676

- HYTROL 48”x120” powered horizonal roller conveyor with forklift slots, s/n: 490677

BOARD MILLING LINE

HARRIS fully automatic board milling line with 4’ and 8’ board capacity including, but not limited to:

- HYTROL 51”x120” variable speed powered horizontal roller conveyor, s/n: 511111

- HYTROL 48”x48” powered horizontal roller conveyor with hydraulic scissor lift table, s/n: n/a

- HYTROL 48”x120” variable speed power horizontal belt conveyor. s/n: 492904

- MFG. UNKNOWN 48” panel edge trim saw, s/n: n/a

- MFG. UNKNOWN 48”x16.5’ variable speed chain transfer conveyor, s/n: n/a

- PAUL KS4G/1500 gang rip saw with 4” stroke, 59” max. workpiece capacity (48” capacity in current configuration), s/n: 98121721

- HYTROL 48”x90” powered variable speed horizontal roller conveyor, s/n: 48391

- (2) MFG. UNKNOWN 48”x160” variable speed chain transfer conveyors, s/n: n/a

- BURKLE bridge-type pick & place vacuum transfer system with 120” horizontal stroke, approx. 48”X48” max. panel size, s/n: n/a

- ELDA 2500 lb. capacity hydraulic scissor lift table, s/n: n/a

- HYTROL 48”x120” powered variable speed horizontal belt conveyor, s/n: n/a

- COSTA 868 53” tandem top & bottom wide belt automatic panel sander with 53” 87 HP single head up-acting sander, 53” 56 HP 3-head down-acting sander, blow off, s/n: C 960405 AC1

- ELDA 2500 lb. capacity hydraulic scissor lift table, s/n: n/a

- EG MD-2024 bridge-type pick & place vacuum transfer system with 120” horizontal stroke, approx. 48”X48” max. panel size, s/n: n/a

- HYTROL 48”x96” power horizontal belt conveyor, s/n: n/a

- HARRIS WOOD custom automated board flipping system with 4’ & 8’ board capacity, s/n: n/a

- HOMAG (2007) OPTIMAT FPR 525/6/10/PW/W/V CNC 6 spindle double end tenoner (currently configured with 4 right-hand spindles & 5 left-hand spindles) with SIEMENS SIMATIC CNC touch screen control, (2) pendant controls, 48” wide capacity, s/n: 0-203-34-3273

- HARRIS WOOD custom spray box with NORDSON EPC 30 spray pattern controller, NORDSON (2007) VERSABLUE glue melter, s/n: LU07H07162

- SMURFIT 450 WRAP A MAT 60”x45’ lace belt conveyor/manual grading station, s/n: n/a

- WEINIG (2005) QUANTUM OPTICUT 450 high speed crosscut saw with OPTICOM touch pad PLC control, automatic measuring system, infeed & outfeed conveyors, s/n: 2436.20

- TORWEGGE (2007) FPR 622/8/03/PW/S tongue & groove and interlocking end-matcher profiler with SEIMENS SIMATIC PLC control, 43” max. working height, 48” working width, 26’-131’ per min. feed range, auto feed, (4) 9 HP right-hand spindles, (4) 9 HP left-hand spindles, adjustable chain belt conveyor, 57”x120” chain link slat transfer conveyor, control cabinet, s/n: 0-440-06-0379

- GRANITEN (2021) floor locking inserter with BECKHOFF digital touch-screen control, s/n: G21-

- M0019

- MATTHEWS VIAJET digital high speed in-line coder, s/n: 02526

- MFG. UNKNOWN 48”x20’ powered horizontal belt conveyor, s/n: n/a

- MFG. UNKNOWN chain transfer conveyor with 4000 lb. capacity scissor lift table, s/n: n/a

- PAUL K34G/1500 (REBUILT 2019) gang rip saw with 4” stroke, 59” max. workpiece capacity, SIEMENS SIMATIC HMI PLC control, 53”x138” infeed & outfeed power horizontal roller conveyors, s/n: 9051168

- PROGESSIVE SYSTEMS 7082 tongue & groove and interlocking end-matcher profiler with (6) right-hand spindles, (6) left-hand spindles, push button control, control cabinet, s/n: PS-14225

- (2) LEWCO 36”x176” powered variable speed horizontal belt conveyors, s/n: n/a

ROLL COATING & UV CURING FINISHING LINES

Roll Coating/UV Curing Finishing Line (1) including, but not limited to:

- MFG. UNKNOWN chain transfer conveyor with AUTOQUIP 2500 lb. capacity scissor lift table, s/n: n/a

- COSTA (2007) BA P4 1350 4-head scrape finisher with (4) 53” wire brush heads, blow off, HASKO PFLI 58”x98” powered roller infeed conveyor, s/n: A70321 AC1

- MFG. UNKNOWN hydraulic panel compressor with 55” wide capacity, 55”x70” powered horizontal roller conveyor, s/n: n/a

- COSTA CCCC 1350 53” 4-head wide belt sander with speeds to 38 FPM, 32.2 HP, blow off, s/n: CL9029

- MFG. UNKNOWN 53” wide 3-station roll coater with adjustable height, multi-spindle brush unit, blow off, approx. 48”x184” powered horizontal belt conveyor, s/n: n/a

- DUBOIS MACHINE CO. UV.HV.48 gas-fired pass-through/UV heat treat/curing system with 52”x3” max. workpiece capacity, 40’ heat treat oven, (2) ELMAG SUPERFICI ultraviolet light modules, 52”x46’ powered horizontal belt conveyor, s/n: 2766

- DUBOIS MACHINE CO. SB 48 scruff sander with 51” wide brush, 48”x77” powered horizontal belt conveyor, blow off, s/n: 2397

- DUBOIS MACHINE CO. RRC 48 stain roll coater with 56” wide roller, approx. 46.5”x84” powered horizontal belt conveyor, s/n: 3344

- MFG. UNKNOWN pass-though UV drying & blow off unit with (2) ELMAG SUPERFICI ultraviolet light modules, (2) blow off units, speeds to 44 FPM, 46.5”x94” powered horizontal belt conveyor, s/n: n/a

- BURKLE hi-abrasion sealer roll coater with 56” wide rolls, speeds to 45 FPM, 47.5”x60” powered horizontal belt conveyor, s/n: n/a

- MFG. UNKNOWN pass-through UV drying unit with (2) ultraviolet light modules, speeds to 46 FPM, 46”x97” powered horizontal belt conveyor, s/n: n/a

- DUBOIS MACHINE CO. roll coater unit with 56” wide rollers, 48”x94” powered horizontal belt conveyor, s/n: n/a

- DUBOIS MACHINE CO. UV.54.4 UV pass-through final sealer drying tunnel with (4) DUBOIS HA56/50 ultraviolet light modules, speeds to 48 FPM, blow off, 48”x180” powered horizontal belt conveyor, s/n: 3358

- DUBOIS MACHINE CO. TSB 48 adjustable multi-station blow off table with 48”x122” powered horizontal belt conveyor, s/n: 2698

- DUBOIS MACHINE CO. RCDW 48 roll coater sealant applicator with 56” wide rollers, speeds to 60 FPM, 48”x78” powered horizontal belt conveyor, s/n: 2695

- MFG. UNKNOWN 46”x184” relax powered horizontal belt conveyor with speeds to 51 FPM, s/n: n/a

- MFG. UNKNOWN 1” topcoat UV drying unit with (2) ELMAG SUPERFICI UV ultraviolet light modules, speeds to 52 FPM, 47”x96” powered horizontal steel mesh belt conveyor, s/n: n/a

- MFG. UNKNOWN roll coater with (2) roller stations, 56” wide rollers, 48”x170” powered horizontal belt conveyor, s/n: n/a

- MFG. UNKNOWN 52”x192” powered horizontal outfeed belt conveyor, s/n: n/a

- MFG. UNKNOWN 48”x120” powered horizontal roller conveyor with AUTOQUIP 2500 lb. capacity scissor lift table, s/n: n/a

- MFG. UNKNOWN 48”x120” powered horizontal roller conveyor with fork slots, s/n: n/a

Roll Coating/UV Curing Finishing Line (2) including, but not limited to:

- HWI Infeed system with (2) AUTOQUIP 2500 lb. capacity hydraulic scissor lift tables, 45”x92” horizontal travelling belt conveyor, 48”x113” powered horizontal belt conveyor, SIEMENS SIMATIC HMI touch screen control, s/n: n/a

- COSTA 80 CC 1350 52” 2-head wide belt sander with 58 HP, blow off, s/n: CL 90 118

- DUBOIS MACHINE CO. PCD 48 2-station roll coater with 56” wide rollers, adjustable height multi-spindle brush unit, 48”x250” powered horizontal belt conveyor, s/n: 3402

- MFG. UNKNOWN roll coater with 56” wide rollers, adjustable height multi-spindle brush unit, 48”x132” powered horizontal belt conveyor, s/n: n/a

- DUBOIS MACHINE CO. HV.UV.48 gas-fired pass-through/UV heat treat/curing system with 56”x5” max. workpiece capacity, 54’ heat treat oven, (3) DUBOIS UV40 ultraviolet light modules, (2) DUBOIS HA35650 ultraviolet light modules, speeds to 62 FPM, 48”x55’ powered horizontal belt conveyor, s/n: 3404

- DUBOIS MACHINE CO. SBD.48 scruff sander with 50” wide brush, speeds to 64 FPM, 48”x120”” powered horizontal belt conveyor, blow off, s/n: 3405

- DUBOIS MACHINE CO. RRO-48 roll coater with 56” wide rollers, 48”x80” powered horizontal belt conveyor, s/n: 3406

- DUBOIS MACHINE CO. UV.48.3.W1 pass-through UV curing oven with (3) DUBOIS HA35650 ultraviolet light modules, speeds to 64 FPM, 48”x120” powered horizontal belt conveyor, blow off, s/n: 3407

- DUBOIS MACHINE CO. RCD.48 roll coater & UV curing oven with 56” wide rollers, (2) DUBOIS HA35650 ultraviolet light modules, speeds to 67 FPM, 48”x144” powered horizontal belt conveyor, s/n: 3410

- DUBOIS MACHINE CO. SBD.48 scruff sander with 50” wide brush, speeds to 64 FPM, 48”x120”” powered horizontal belt conveyor, blow off, s/n: 3408

- DUBOIS MACHINE CO. RCD.D48 hi-abrasion roll coater & UV curing oven with 56” rollers, (2) DUBOIS HA35650 ultraviolet light modules, blow off, 48”x20” powered horizontal belt conveyor, s/n: 3409

- DUBOIS MACHINE CO. UV.48.5.W1 pass-through UV curing oven with (5) DUBOIS HA35650 ultraviolet light modules, speeds to 67 FPM, 48”x120” powered horizontal belt conveyor, blow off, s/n: 3411

- DUBOIS MACHINE CO. SBT.48 adjustable multi-station blow off table with 48”x122” powered horizontal belt conveyor, s/n: 3412

- MFG. UNKNOWN roll coater with 56” rollers, 48”x72” powered horizontal belt conveyor, s/n: n/a

- MFG. UNKNOWN topcoat UV drying unit & roll coater with (2) DUBOIS HA35650 ultraviolet light modules, speeds to 70 FPM, 56” rollers, 48”x192” powered horizontal steel mesh belt conveyor, s/n: n/a

- MFG. UNKNOWN roll coater with 56” rollers, speeds to 70 FPM, 48”x19’ powered horizontal belt conveyor, s/n: n/a

- DUBOIS MACHINE CO. UV.48.6.W2 pass-through UV curing oven with (8) DUBOIS HA35650 ultraviolet light modules, speeds to 70 FPM, 48”x20’ powered horizontal belt conveyor, blow off, s/n: 3415

WOODWORKING EQUIPMENT

- COSTA AKF CCT 1350 52” 3-head wide belt sander with SIEMENS SIMATIC HMI touch screen control, 8.5 HP, s/n: 990414 AC5

- COSTA C 1350 53” single head wide belt sander with digital microprocessor control, 52 HP, blow off, s/n: 980708/AC3

- VIET VALERIA 1C 55” single head wide belt sander with SCS digital microprocessor control, power feed & blow off, 15 HP drive motor, 480V/3PH, s/n: 9605199

- WEINIG U25E automatic 3-spindle feed-through molder with 10” capacity, s/n: 95409

- HARRIS WOOD custom high speed 6-spindle edge trim profiler with SIEMENS SIMATIC HMI touch screen control, max. 7” board capacity, pneumatic clamping, s/n: n/a

- PROGESSIVE SYSTEMS 7028M tongue & groove and interlocking side-matcher profiler with (6) 15 HP right-hand spindles, (6) 15 HP left-hand spindles, s/n: PS-14223

- COSTA end-matcher profiler with 100” capacity max. workpiece length, s/n: n/a

- MFG. UNKNOWN side beveling machine with PLC control, s/n: n/a

- HARRIS WOOD 4-wheel custom hand scraping machine with 32” dia. wheels, power feed, chain belt conveyor, s/n: n/a

- MFG. UNKNOWN automatic re-rip saw with 18” capacity, 12” blade, push button control, s/n: n/a

- HASKO HSS automatic circular scrap saw with 16” blade, s/n: 0651402

- (3) HW BEACH 9021 10” heavy duty sliding table-type rip saws, s/n: 2395, n/a, 9512

- JET SUPERSAW 10” table saw with 27”x45” table, s/n: 04110053

- POWERMATIC MODEL 66 12” table saw with 28”x36” table, s/n: 9166614

- PRECISON PRODUCTS HC14RH 14” up-acting cut off saw with 7.5 HP, s/n: 58

- FLETCHER FT-30 6”x64” heavy duty horizontal belt sander with 5 PH, s/n: 70105

- PROGRESS PMC-150 6”x48” heavy duty horizontal belt sander with 2 HP, s/n: 97172

CONVENTIONAL MACHINE TOOLS

- JET JTM-4VS vertical milling machine with 9”x48” table, infinitely variable speeds to 4200 RPM, DITRON 3-axis DRO, power table, power feed, R8 collet spindle, coolant, s/n: 7091102

- MSC 100-1599 vertical milling machine with 9”x48” table, speeds to 4200 RPM, SARGON 2-axis DRO, power table, coolant, s/n: 470621

- BRIDGEPORT SERIES I vertical milling machine with 9”x32” table, speeds to 2700 RPM, s/n: 13641

- JET 1880S gap bed engine lathe with 18” swing over bed, 24” swing in gap, 80” distance between centers, 1.5” spindle bore, speeds to 1500 RPM, 14” 4-jaw chuck, inch/metric threading, steady rest, coolant, s/n: 810108H

- KINGSTON HJ-1700 gap bed engine lathe with 18” swing over bed, 22” swing in gap, 65” distance between centers, 1.5” spindle bore, speeds to 2000 RPM, 10” 3-jaw chuck, inch/metric threading, steady rest, coolant, taper attachment, s/n: CH91818

- YAM 1769 engine lathe with 20” swing over bed, 55” distance between centers, 2” spindle bore, speeds to 1800 RPM, 12” 4-jaw chuck, inch/metric threading, coolant, s/n: 86751

- BRADFORD 18X100 engine lathe 18” swing over bed, 100” distance between centers, 1.5” spindle bore, speeds to 400 RPM, 12” 3-jaw chuck, inch/metric threading, steady rest & follow, s/n: 7197

- CHEVALIER FSG-1832AD automatic hydraulic surface grinder with 18”x32” table, 16”x32” electromagnetic chuck, 14” wheel, wheel dresser, incremental down feed, coolant, s/n: n/a

- BROWN & SHARPE NO. 2L conventional surface grinder with 6”x18” electromagnetic chuck, 6” wheel, coolant, s/n: n/a

- WILTON 8020 vertical band saw with 24”x24” tilting table, 20” throat, 12” max. workpiece height, blade welder/grinder, s/n: 80E1009

- DOALL C916M horizontal band saw with 9”x16” cutting capacity, manual vise, coolant, s/n: 527-991165

- WEINIG R912 RONDAMAT automatic tool cutter/grinder, s/n: 912-342

- VOLMER CHC-20-H circular saw blade sharpener with 3”-27.5” capacity, s/n: 2060

- VOLMER bench-type tool cutter/grinder, s/n: n/a

- MANLEY 80 ton capacity hydraulic h-frame press with 36” daylight opening, 45” distance between uprights, s/n: 599

- MFG. UNKNOWN 12 ton capacity h-frame shop press with 24” distance between uprights, s/n: n/a

- KALAMAZOO K10 10” abrasive cut off saw with stand, s/n: n/a

- WILTON 4660 6”x24” tilting horizontal belt sander, s/n: 15116

- MFG. UNKNOWN 8” double end pedestal grinder, s/n: n/a

- RIDGID TS2400-1 10” portable tilting arbor table saw with 20”x30” table, s/n: U045156820

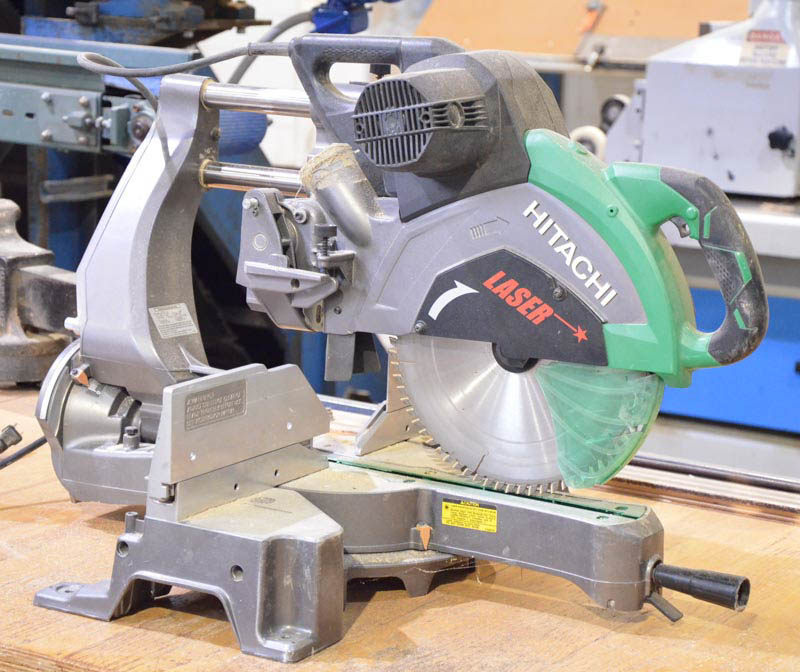

- HITATCHI C 12RSH2 12” sliding compound miter saw with laser guide, s/n: C562505

- KOBALT 1413794 10” sliding compound miter saw with laser guide & RYOBI stand, s/n: 081731

PACKAGING EQUIPMENT

- HARRIS WOOD PFL-2 packaging system with SIEMENS SIMATIC touch screen control, bridge-type pick & place vacuum carton sealer, NORDSON SERIES 3500V hot melt glue applicator, s/n: n/a

- DORELL SW20AI combination automatic plastic wrap dispenser & heat shrink tunnel with 22”x16” max. tunnel opening, s/n: S0999099

- (6) MOSCA RO-M-P4 portable automatic strapping machines with 22”x16” capacity, s/n: 77421, 72611, 46163, 76552, 76553, 80344

- (2) SAMUEL P-710 portable automatic strapping machine with 19”x13” max. capacity, s/n: n/a, n/a

- STRAPACK (2014) JK-5000 portable automatic strapping machine with 25”x19” max. capacity, s/n: 14004557-504

FACTORY EQUIPMENT

- LOAD KING 100391-110-6031 10 HP hydraulic vertical cardboard baler, s/n: 12599

- GORBEL 2 ton capacity free-standing jib arm with 17’ span, 8.5’ height under hook, 2 ton WRIGHT-WAY electric hoist, s/n: n/a

- (3) ROBERTS 26” table-top manual material cutting stations, s/n: n/a

Scrap Wood Handling System consisting of:

- HYTROL 24”x20’ powered incline cleat belt conveyor, s/n: n/a

- Approx. 20”x35’ overhead powered horizontal belt conveyor with safety cage, s/n: n/a

- Approx. 20”x 225’ overhead powered horizontal belt conveyor with safety cage, s/n: n/a

- Approx. 24”x 175’ overhead powered horizontal belt conveyor, s/n: n/a

- MFG. UNKNOWN in-line metal detector, s/n: n/a

- WILLIAMS crusher/pulverizer with 200 HP direct drive motor, s/n: 19027

- NEW YORK BLOWER 29LS transport blower with 75 HP motor, s/n: n/a

- MFG. UNKNOWN 32”x24’ powered incline cleat belt conveyor with loading hopper, s/n: n/a

(2) INDUSTRIAL BOILER CO DWF-500-300 biomass & natural gas fired boilers with SIEMENS PLC controls, 2675 sq/ft heating area, feed equipment, water transfer pumps, condensate recovery tower, s/n n/a

PNEUMAFIL plant dust collection system including, but not limited to:

- (5) PNEUMAFIL approx. 18’ dia. x 25’H cyclone bins

- (6) KOGER air rotary air lock valves

- (5) NEW YORK BLOWER 49TV blowers with 300 HP motor

- MFG. UNKNOWN transfer blower with 125 HP motor

- MFG. UNKNOWN transfer blower with 100 HP motor

- MFG. UNKNOWN transfer blower with 75 HP motor

TESTING & INSPECTION EQUIPMENT

- PGC AA-5474 environmental testing chamber with 10’x8’x8.5’H outer dimensions, HONEYWELL chart recorder, s/n: 842P-01

- ASSOCIATED ENVIRONMENTAL SYSTEMS HD-464 environmental testing chamber with HONEYWELL F4 digital microprocessor control, 48”x48”x48” stainless steel chamber, 220V/3PH/60HZ, s/n: 7530

- MITUTOYO PJ-A3000 13.5” optical comparator with built in 2-axis DRO, s/n: 360110

- HP PREKWINKEL 12” optical comparator with RATIONAL DC-3000 3-axis DRO, s/n: 06070563

ALSO:

- (65+) Sections of adjustable pallet racking; MROs & SPARE PARTS including ELECTRIC MOTORS up to 300 HP, TRANSFORMERS up to 112.5 KVA, disconnect switches, pumps; fireproof cabinets; (2) biomass boilers with gas backup; (2) 144” dia. x 144”H holding tanks; conventional inspection equipment – outside & inside micrometers, Vernier calipers, depth gauges, dial gauges; HUGE QUANTITY of WIP flooring boards including HICKORY, OAK, MAPLE, WHITE OAK, RED OAK, RED MAPLE; STORES INVENTORY including: fastening hardware with index parts bins and steel shelves, steel shelves with parts and components, stainless steel and conventional plumbing fixtures and hardware with shelving, stainless steel and conventional fastening hardware with shelving, (25+) sections of steel shelving with gaskets, rubber flex couplers, brand new FAG/SKF/TIMKEN/NSK BEARINGS inventory, repair kits, hardware, plumbing fixtures, spare electric motors up to 200 HP, spare pneumatic and hydraulic cylinders, flanges, belts, electrical and electronic parts and components, ferrous and nonferrous raw materials in bar, tube and off cuts; sealed drums of wood stain and MORE!