Natural Gas Pipe Manufacturing Facility

Late Model & Lightly Used Fabricating Event!

Date

Wednesday, December 14, 2016

Start Time

10:30 AM EST

Inspection

Tuesday, December 13 from 9 AM to 5 PM Assets located at: 12 King St W, Saint John, NB E2M 7Y8

Removal

Small items: Wednesday, December 15 by 5 PM

Remaining items: Friday, December 23 by 5 PM

Industry

This facility never ran full production, and is a great opportunity to acquire late model fabricating equipment before the year end! A brief summary of assets to be included are as follows: PANGBORN (LATE MODEL, HARDLY USED & IN LIKE NEW CONDITION) ES-1844-12, 8 wheel structural shot blast system with (8) 25HP RIM-LOC ROTOBLAST blast wheels, PANGBORN cartridge type dust collector, media reclamation system, manual spot check/cleaning station, etc.; LINCOLN/FANUC (2008) 6 axis robotic welding cell with LINCOLN ELECTRIC safety enclosure & turnstile, FANUC ARC MATE 120ic/10L 6 axis robot, nozzle cleaner, teach pendant etc.; (25+) IRCO & PRESTON EASTIN (LATE MODEL) adjustable power tank turning & idler rolls up to 30 ton capacity, several variable speed; Large quantity of steel pipe handling/transfer conveyor systems; PANDJIRIS 30-12, tilt & rotate welding positioner with pendant control; IRCO 3K, tilt & rotate welding positioner with variable speed & foot pedal control; IRCO manual rotating welding positioner with stand; (4) LINCOLN POWER WAVE 455M/STT, advanced process digital welders with 10M wire feeders; (3) LINCOLN DC-655, multi-process digital welders; LINCOLN INVERTEC STTII, advanced process digital welder; (2) LINCOLN INVERTEC V350-PRO, multi-process digital welders with DOUBLE HEADER wire feeders; (3) RED-D-ARC E500 welding power supplies; HOBART welding power source; LINCOLN COOL-ARC 40 welding chiller; LINCOLN portable fume extractor; (3) LINCOLN cartridge filter systems; (2) HOISTING 20 ton traveling gantry bridge cranes with (2) STAHL 10 ton hoists; HOISTING 20 ton & approx. 100’ single girder bridge crane with (2) STAHL 10 ton hoists; BAXTER VERTICUT horizontal metal cutting saw; (2) ENERPAC hydraulic tube & pipe benders; GATES hydraulic hose crimper; (4) JET & KITO 1 ton electric hoists; INGERSOLL RAND (2008) UP6-50PE-125, 50HP air compressor; INGERSOLL RAND (2008) NVC300A600 air dryer; (2) HAYWARD-GORDON pumps; NLB 630E-7/8, 6000 PSI hydraulic power pack; (2) ICE large volume industrial plant heaters; LARGE ASSORTMENT OF contractor safety & electrical supplies, Stainless steel & carbon steel storage tanks with agitators/mixers, skid mounted gas fired boilers, LARGE QTY of welding equipment & accessories, welding rod ovens, hydraulic power packs, factory support equipment & MUCH MORE!

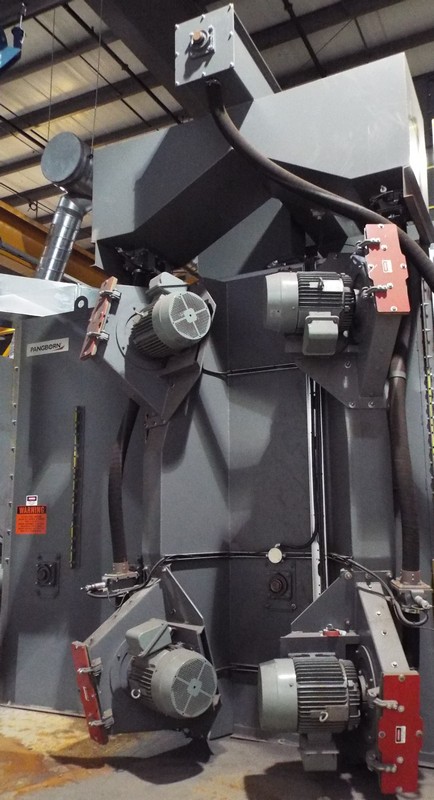

LATE MODEL SHOT BLAST

- PANGBORN (2008 - LIKE NEW CONDITION) ES-1844-12 8 wheel structural shot blast system with (8) 25HP RIM-LOC ROTOBLAST blast wheels, PANGBORN cartridge type dust collector, media reclamation system, manual spot check/cleaning station, s/n: ES-1844-12/5080232

*this machine is currently set up with a silhouette panel to accommodate blasting for 36” diameter steel pipe. The silhouette panel can be easily removed and replaced with finger seals for a much greater blasting capacity due to the internal cavity size. Full diagrams for the machine with detailed specifications will be available shortly.

ROBOT WELDING CELL

- LINCOLN/FANUC (2008) 6 axis robotic welding cell with LINCOLN ELECTRIC safety enclosure & turnstile, FANUC ARC MATE 120ic/10L 6 axis robot, LINCOLN POWERWAVE 455M/STT welding power source with LINCOLN COOL-ARC 40 water cooler, ABICOR BINZEL torch cleaning station, FANUC system R-30iA control, FANCU digital teach pendant, hydraulic turntable, s/n: n/a

WELDERS

- (2) LINCOLN INVERTEC V350-PRO portable multi-process digital welders with LINCOLN DOUBLE HEADER DH-10 digital dual roll wire feed, cables and guns, s/n: U1080902754, U1080902752

- LINCOLN POWERWAVE 455M/STT advanced process welder with LINCOLN POWERFEED 10M digital wire feed, cables and gun, s/n: U1080408669

- LINCOLN NA-5 digital sub arc welder with POWERFEED 10M digital wire feed, submerged arc welding head, flux hopper, s/n: U1080710648

- (3) LINCOLN IDEALARC DC-655 digital arc welding power sources, s/n: U1080112262, U1080212600, U1060917606

- LINCOLN POWERWAVE 455M/STT welding power source, s/n: U1070202619

- LINCOLN INVERTEC STT II digital MIG welding power source, s/n: U1060215439

- (2) MILLER DELTAWELD 452 digital MIG welding power sources, s/n: n/a, n/a

- HOBART FABSTAR 4030 MIG welder with HOBART 17 wire feed, cables and gun, s/n: 294WS34958

- HOBART FABSTAR 4030 MIG welding power source, s/n: n/a

WELDING POSITIONERS

- IRCO 3K welding positioner with 30,000 LB. max. Capacity, 36”x36” table, pendant control, foot pedal, s/n: 30151

- MFG. UNKNOWN rolling welding positioner with LINCOLN NA-5 digital sub arc welder with submerged arc welding head, flux hopper, s/n: n/a

- MFG. UNKNOWN dual head welding positioner with MILLER arc welding head, submerged arc welding head, flux hopper, joystick control, flux tank, s/n: n/a

- GULLCO GPP-200-M-B table top welding positioner with pendant control, foot pedal, s/n: n/a

MATERIAL HANDLING

- HOISTING enclosed single girder top running bridge crane with 20 ton capacity, (2) STAHL 10 ton electric hoists, approx. 100’ span, approx. 20’ height under hook, approx. 120’ runway with bus bar and columns, s/n: 11610/03/09

- (2) HOISTING GANTRY-DG double girder top running travelling gantry bridge crane with 20,000 LB. capacity, (2) STAHL 10 ton electric hoists, approx. 20’ span, approx. 10’ height under hook, s/n: CF7489-B, CF7489-A

- (4) JET & KITO 1 ton electric hoists

TANK TURNING ROLLS

- PRESTON-EASTIN tank turning roll set with (1) powered drive roll, (2) idler rolls, 30 ton max. Capacity, variable speed drive, approx. 15” diameter adjustable wheels with approx. 48” total travel, s/n: n/a

- IRCO tank turning roll set with (1) powered drive roll, (1) idler roll, variable speed drive, approx. 12” diameter adjustable wheels with approx. 48” total travel, pendant control, s/n: 30270

- MFG. UNKNOWN tank turning roll set with (1) powered drive roll, (1) idler roll, variable speed drive, approx. 16” diameter adjustable wheels with approx. 10” total travel, s/n: n/a

- PRESTON-EASTIN powered drive tank turning roll with variable speed drive, approx. 15” diameter wheels, s/n: n/a

- (19) ASSORTED combination powered drive/idler angled tank turning rolls with single speed drive, approx. 12” stationary wheels, s/n NA

- (10) ASSORTED idler tank turning rolls with approx. 15” diameter adjustable wheels with approx. 20” total travel, s/n NA

SHOP EQUIPMENT

- INGERSOLL-RAND (2008) UP6-50PE-125 50 HP rotary screw air compressor, s/n: PG4572U08294

- INGERSOLL-RAND (2008) NVC300A600 digital refrigerated air dryer, s/n: 315827

- BLUE M POM-2006C-1 electrode stabilizing oven with 343 C / 650 F max. Temperature, s/n: n/a

- BAXTER VERTICUT horizontal band saw with 370 SFPM, 28”x12” capacity, s/n: n/a

- BURR-KING MODEL 960 deburring machine

- GATES digital hydraulic hose crimper

- RICE LAKE platform scale with 2,500 KG. max. Capacity, RICE LAKE DRO

- LINCOLN LFA 4.1 portable snorkel fume extractor

- ZEROMAG ZM100A portable digital demagnetizer

SUPPORT EQUIPMENT

- ICE AC-060/400 propane industrial/commercial package furnace with 5,312.5 BTU/hour max. capacity, 85,000 max. CFM, s/n: 12066827A1, N/A

- NLB CORP. 630E-7/8 hydraulic power pack with 30 HP, 6000 PSI

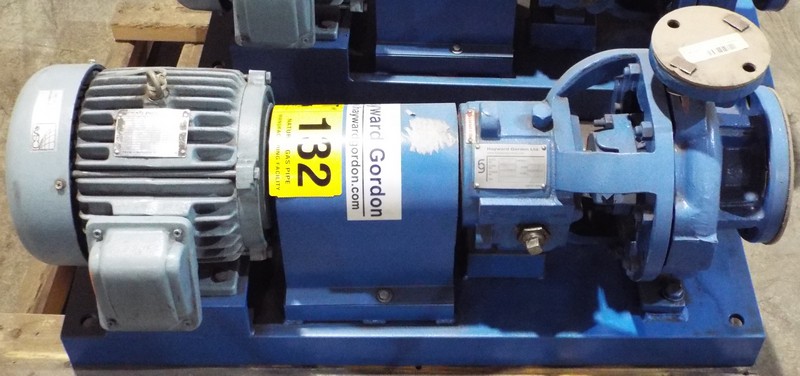

- (2) HAYWARD-GORDON centrifugal pump with 15 HP WESTINGHOUSE electric motor

- PARKER T490 skid mounted boiler with 490,000 BTU max. input, s/n: 46681

- YORK-SHIPLEY gas-fired boiler with 860,000 BTU max. input

- EMS 4 bank PLC control cabinet with OMRON digital control

ALSO:

LARGE QUANTITY of conveyor components, hydraulic power packs, VARIED ASSORTMENT of lab equipment, welding wire (NEW in box), pallet racking, stainless steel & carbon steel storage tanks with agitators/mixers, electrical supplies, hardware & fittings, and MUCH MORE!