Former Assets of

Velan Inc.

Major Multi-Million Dollar CNC Machining Event!

Date

Thursday, June 25, 2020

Start Time

9:30 AM EDT

Inspection

BY APPOINTMENT ONLY. Please email info@corpassets.com to arrange a date and time.

Removal

All assets must be removed no later than Friday, July 17 by appointment only.

Location

Assets Located at 3 Facilities in Montreal, QC

Industry

Corporate Assets Inc. is pleased to announce its recent acquisition of assets no longer required in the continuing operations of Velan Inc. in Montreal, Canada. Velan Inc. is a global leader in the manufacturing of high-quality valves and associated components, used in a wide range of industries such as Nuclear, Petrochemical, Pulp & Paper, Marine, Pharmaceutical etc. With ASME, ISO 9001 and numerous other facility standards maintained, Velan's equipment has been maintained to the highest standards. This is an exceptional opportunity that must not be missed!

A brief summary of assets are as follows: PIETRO CARNAGHI (1996) ATF14, CNC twin pallet combination vertical turning and milling center equipped with right angle & vertical milling heads, ATC's for both turning and milling attachments, etc. (LATE SIEMENS CNC RETROFIT); TOSHIBA SHIBAURA (12-2012) TUE-150(S) CNC vertical boring and live milling center; TOSHIBA SHIBAURA (09-2008) TUE-150(S) CNC vertical boring and live milling center; TOSHIBA SHIBAURA (12-2008) TUE-150(S) CNC vertical boring and live milling center; TOSHIBA SHIBAURA (08-2006) TUE-15 CNC vertical boring and live milling center; TOSHIBA SHIBAURA (1999) TMF-10 CNC vertical boring and live milling center; MAZAK (07-2012) MEGATURN NEXUS900 CNC vertical turning and live milling center; KEARNS & RICHARDS (R&R 2017) KHT130L CNC table type horizontal boring mill; KEARNS & RICHARDS (R&R 2012) 125L CNC table type horizontal boring mill; KEARNS & RICHARDS (R&R 2002) 125L CNC table type horizontal boring mill; MAZAK (08-2006) FH-6800 CNC twin-pallet horizontal machining center w/ facing head provisioning; MAZAK (08-2006) FH-6800 CNC twin-pallet horizontal machining center w/ facing head provisioning; OKUMA (2003) MC-600H high speed CNC multi-pallet horizontal machining center w/ 6 pallet pool; TOSHIBA SHIBAURA (2000) NX76 CNC twin-pallet horizontal machining center; TOSHIBA SHIBAURA (12-1998) NX76 CNC twin-pallet horizontal machining center; TOSHIBA SHIBAURA (12-1998) NX76 CNC twin-pallet horizontal machining center; NIIGATA HN80FC twin-pallet CNC horizontal machining center; DAEWOO ACE-80 twin-pallet CNC horizontal machining center; DAEWOO (1998) ACE-H500 twin-pallet CNC horizontal machining center; DAEWOO ACE-80 twin-pallet CNC horizontal machining center; MAZAK (2014) MULTIPLEX MP6300-II twin spindle twin turret CNC live milling and turning center; MAZAK (2007) MULTIPLEX MP6250 twin spindle twin turret CNC live milling and turning center; MORI SEIKI (R&R 2008) SL8 CNC turning center w/ 10.2" bar capacity; (3) DAEWOO PUMA 10HC CNC turning centers; SMT (RETROFIT 2005) SWEDTURN 12 CNC turning center; OKUMA (2000) MX-45VAE CNC vertical machining center; SUPERMAX (2007) XV-1020A CNC vertical machining center; MAZAK (2000) MTV 515/40N CNC vertical machining center; MAZAK (1997) MTV-515/40N CNC vertical machining center; TOS SUS63 28" x 85" engine lathe; EUMEGA (2001) MDV4 vertical turret milling machine; LARGE OFFERING OF CNC machine tool accessories, precision tooling and fixtures, high quality inspection equipment, welding equipment, general factory support equipment & MUCH MORE!

* ADDITIONAL ASSETS HAVE BEEN ADDED TO THE SALE! *

Quality brand name machine tools, welding and fabricating equipment, material handling and factory equipment featuring: TRAK CNC vertical turret mill; BLANCHARD No20 rotary surface grinder, CHEVALIER FSG-3A818 hydraulic surface grinder; CINCINNATI MILACRON 2MT tool and cutter grinder; OLIVER drill grinder; MITUTOYO FN905 CMM; (5+) MILLER MIG & TIG welders; (5+) LINCOLN MIG & TIG welders; (10+) LINCOLN, NEDERMAN and CPI portable welding fume extractors; (5) IRCO tilt & rotate welding positioners with capacities from 1,000 to 4,000 lbs; DIVERSITECH down draft sanding tables; PANDJIRIS 30-A6 welding manipulator; MOTOMAN robotic welding cell; SULLAIR 100 HP compressor; CANABLAST (2012) shot blast cabinet with media recovery; SULLAIR 50 HP compressor; (2) SULLAIR refrigerated air dryers; HYSTER XL 18,000 LBS CAP forklift; (2) TOYOTA 5,000 LBS capacity forklifts; (2) NISSAN 5,000 LBS capacity forklifts; (3) CROWN late model electric pallet trucks; SKYJACK SJ-III electric scissor lift; coolant-oil separators; ERIEZ magnetic coolant filtration system; large selection of t-slot tables; machine tool accessories including KURT vises, tombstones and fixtures; bench grinders; floor type drill presses; (10+) ROUSSEAU 5 to 7 drawers tool cabinets with perishable tools & MORE!

THE EXCLUSIVE RIGGER FOR THIS SALE IS:

Ex Trans Cargo Inc.

Kerry-Ann Labranche

Direct Line: 1.514.894.5644

klabranche@extranscargo.com

wwww.extranscargo.com

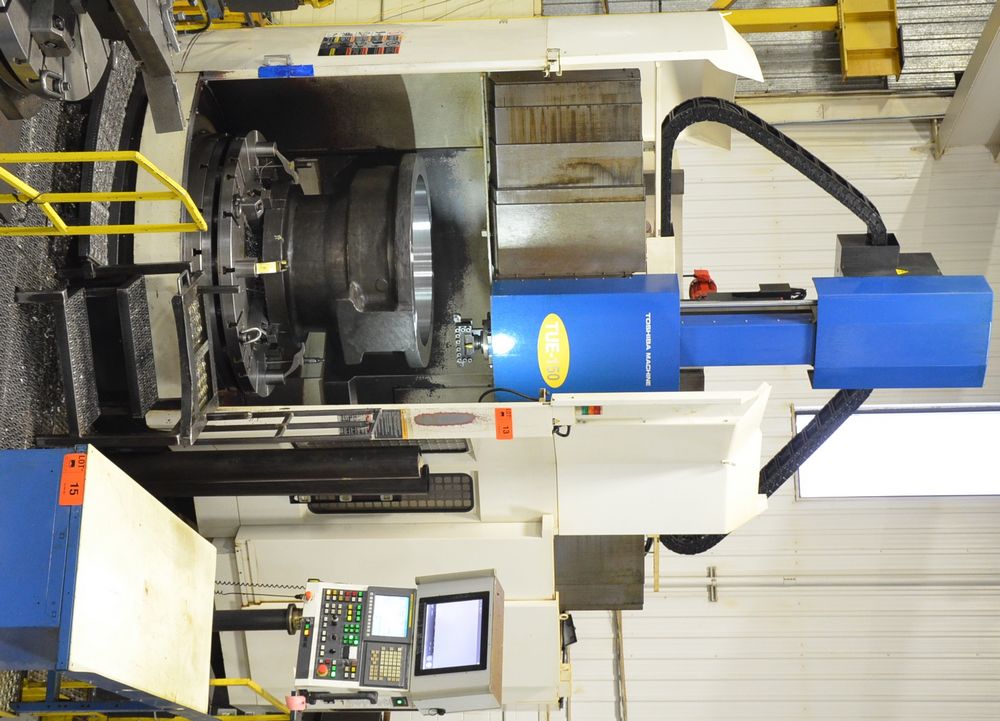

CNC VERTICAL BORING AND LIVE MILLING CENTERS

- PIETRO CARNAGHI (1996) ATF 14 TM CNC twin-pallet vertical turning and live milling center with SIEMENS SIMUMERIK 840C CNC control, 55” diameter pallets, 63” maximum machining diameter, 59” maximum machining height, 65.9” maximum distance table to cross rail, travels X-152.70”, Z-49.20”, 28” cross rail vertical travel, 12 station head changer with (5) turning heads, (2) right-angled CAPTO milling heads, (1) CAT50 straight milling head, (1) CAT50 right angled milling head and (1) RENISHAW MP3 touch probe, 40 station ATC with (30) CAT50 and (10) CAPTO VDO stations, speeds to 350 RPM in (2) ranges with 80 HP main drive motor, 3,000 RPM maximum milling speed with 40 HP milling drive motor, coolant, chip conveyor, 460V/3PH/60HZ, s/n: 96471 (Asset # 15203)

- TOSHIBA SHIBAURA (12-2012) TUE-150(S) CNC vertical boring and live milling center with FANUC OI-TD CNC control, 57.09” table diameter, 78.74” maximum swing, 61.02” maximum machining height, 71.74” maximum machining diameter, 67.72” maximum height from table top to ram bottom, travels X-49.22”, Z-35.43”, 39.37” cross rail vertical travel, table speeds to 400 RPM in (2) ranges, #50 spindle taper, milling spindle speeds to 3,000 RPM, 18 station ATC, through spindle coolant, chip conveyor, 200-220V/3PH/50-60HZ, s/n: 440614 (Asset # 15209)

- TOSHIBA SHIBAURA (09-2008) TUE-150(S) CNC vertical boring and live milling center with FANUC OI-TC CNC control, 57.09” table diameter, 78.74” maximum swing, 61.02” maximum machining height, 71.74” maximum machining diameter, 67.72” maximum height from table top to ram bottom, travels X-49.22”, Z-35.43”, 39.37” cross rail vertical travel, table speeds to 400 RPM in (2) ranges, #50 spindle taper, milling spindle speeds to 3,000 RPM, 18 station ATC, through spindle coolant, chip conveyor, 200-220V/3PH/50-60HZ, s/n: 440389 (Asset # 15505)

- TOSHIBA SHIBAURA (12-2008) TUE-150(S) CNC vertical boring and live milling center with FANUC OI-TC CNC control, 57.09” table diameter, 78.74” maximum swing, 61.02” maximum machining height, 71.74” maximum machining diameter, 67.72” maximum height from table top to ram bottom, travels X-49.22”, Z-35.43”, 39.37” cross rail vertical travel, table speeds to 400 RPM in (2) ranges, #50 spindle taper, milling spindle speeds to 3,000 RPM, 18 station ATC, through spindle coolant, chip conveyor, 200-220V/3PH/50-60HZ, s/n: 440427 (Asset # 15507)

- TOSHIBA SHIBAURA (08-2006) TUE-15 CNC vertical boring and live milling center with FANUC series 18-T CNC control, 59.06” table diameter, 70.87” maximum swing, 67.72” maximum height from table top to ram bottom, 59.06” maximum machining height, 70.88” maximum machining diameter, travels X-47.25”, Z-35.43”, 41.34” maximum arm vertical travel, table speeds to 300 RPM in (2) ranges, #50 spindle taper, milling spindle speeds to 3,000 RPM, 12 station ATC, coolant, chip conveyor, 200-220V/3PH/50-60HZ, s/n: 440269 (Asset # 15702)

- TOSHIBA SHIBAURA (1999) TMF-10 CNC vertical boring and live milling center with FANUC 18i-T CNC control, 40” table diameter, 47.2” maximum swing, 43.3” maximum height table top to ram bottom, 36.6” maximum turning height, 47.2” maximum turning diameter, travels X-48.5”, Z-31.5”, C-0.001 degrees indexing, table speeds to 500 RPM in (2) ranges, milling spindle speeds to 2,500 RPM, BT50 spindle taper, 24 station ATC, through spindle coolant, chip conveyor, 50 HP main spindle motor, 20 HP milling spindle motor, FILTERMIST FX4200 mist extractor, 200-240V/3PH/60HZ, s/n: 460005 (Asset # 15502)

- MAZAK (07-2012) MEGATURN NEXUS900 CNC vertical turning and live milling center with MAZATROL MATRIX NEXUS CNC control, 36” table diameter, 39.37” maximum swing, 36.22” maximum machining diameter, 31.50” maximum machining height, travels X-18.50”, Z-34.49”, 12 station turret with (1) live station, 12 station ATC, table speeds to 1250 RPM, speeds to 4000 RPM milling spindle, coolant, chip conveyor, 230-460V/3PH/50-60HZ, s/n: 238678 (Asset # 15704)

CNC TABLE TYPE HORIZONTAL BORING MILLS

- KEARNS & RICHARDS (R&R 2017) KHT130L CNC table type horizontal boring mill with FANUC SERIES 3Ti-MODEL B 5 axis CNC control, 5.11” spindle, 102”x49.25” table, travels X (table cross) – 118.00”, Y (vertical) – 59.00”, Z (spindle quill) – 31.00”, W (table longitudinal) 61.00”, U (facing head slide) – 7.60”, #50 spindle taper, speeds to 1120 rpm, coolant, chip conveyor, 600V/3PH/50-60HZ, s/n 8000 (Asset # 17206)

- KEARNS & RICHARDS (R&R 2012) 125L CNC table type horizontal boring mill with FANUC SERIES 31i-MODEL A5 5 axis CNC control, 4.92” spindle, 60”x60” table, travels X (table cross) – 90.98”, Y (vertical) – 71.20”, Z (spindle quill) – 28”, W (table longitudinal) 58.70”, U (facing head slide) – 7.60”, #50 spindle taper, speeds to 1120 rpm, coolant, chip conveyor, 600V/3PH/50-60HZ, s/n 7297 (Asset # 17209)

- KEARNS & RICHARDS (R&R 2002) 125L CNC table type horizontal boring mill with FANUC 18i-M 5 axis CNC control, 4.92” spindle, 60”x60” table, travels X (table cross) – 90.98”, Y (vertical) – 71.20”, Z (spindle quill) – 28”, W (table longitudinal) 58.70”, U (facing head slide) – 7.60”, #50 spindle taper, speeds to 1120 rpm, coolant, chip conveyor, 600V/3PH/50-60HZ, s/n 7312 (Asset # 17202)

CNC HORIZONTAL MACHINING CENTERS

- MAZAK (08-2006) FH-6800 CNC twin-pallet horizontal machining center with MAZATROL 640M CNC control, 25”x25” pallets, travels X-41.34”, Y-31.50”, Z-34.65”, W-360,000 positions in 0.001 degree increments, CAT50 spindle taper, speeds to 7,000 RPM, facing head spindle provisioning, 120-station ATC, high pressure coolant through spindle, RENISHAW OMNI2 touch probe system, 200-220V/3PH/50-60HZ, s/n: 189505 (Asset # 20110)

- MAZAK (2001) FH-6800 CNC twin-pallet horizontal machining center with MAZATROL PC FUSION 640 CNC control, 25”x25” pallets, travels X-41.34”, Y-31.50”, Z-34.65”, W-360,000 positions in 0.001 degree increments, CAT50 spindle taper, speeds to 7,000 RPM, facing head spindle provisioning, 120-station ATC, high pressure coolant through spindle, 200-220V/3PH/50-60HZ, s/n: 159217 (Asset # 20507)

- OKUMA (2003) MC-600H CNC multi-pallet horizontal machining center with OKUMA OSP7000M CNC control, 25”x25” pallet, travels X-39.37”, Y-31.50”, Z-29.53”, W-360,000 positions in 0.001 degree increments, CAT 50 spindle taper, speeds to 10,000 RPM, 25 HP main spindle motor, 72-station ATC, coolant through spindle, chip conveyor, (6) pallet pool system with APC automatic pallet changer, 220-440V/3PH/60HZ, s/n: 0376 (Asset # 20109)

- TOSHIBA SHIBAURA (2000) NX76 CNC twin-pallet horizontal machining center with TOSNUC T888 CNC control, 24.80”x29.50” pallets, travels X-33.46”, Y-29.92”, Z-30.70”, W-360,000 positions in 0.001 degree increments, CAT50 spindle taper, speeds to 8,000 RPM, 60-station ATC, coolant through spindle, chip conveyor, 220250V/3PH/50-60HZ, s/n: 212958 (Asset # 20108)

- TOSHIBA SHIBAURA (12-1998) NX76 CNC twin-pallet horizontal machining center with FANUC CNC control, 24.80”x29.50” pallets, travels X-33.46”, Y-29.92”, Z-30.70”, W-360,000 positions in 0.001 degree increments, CAT50 spindle taper, speeds to 8,000 RPM, 38-station ATC, coolant through spindle, chip conveyor, 220250V/3PH/50-60HZ, s/n: 212830 (Asset # 20509)

- TOSHIBA SHIBAURA (12-1998) NX76 CNC twin-pallet horizontal machining center with TOSNUC 888 CNC control, 24.80”x29.50” pallets, travels X-33.46”, Y-29.92”, Z-30.70”, W-360,000 positions in 0.001 degree increments, CAT50 spindle taper, speeds to 8,000 RPM, 38-station ATC, coolant through spindle, chip conveyor, 220250V/3PH/50-60HZ, s/n: 212840 (Asset # 20611) (LOCATION – PLANT 4, GRANBY, QC)

- NIIGATA HN80FC twin-pallet CNC horizontal machining center with FANUC series 15-M CNC control, 31.5”x31.5” pallets, travels X-60.20”, Y-33.50”, Z-43.30”, 90-station ATC with (60) position CAT50 and (30) position HSK, coolant, chip conveyor, 230V/3PH/60HZ, s/n: 46250024 (Asset # 20205) (PROFESSIONALLY DISMANTLED - READY FOR SHIPPING)

- DAEWOO ACE-80 twin-pallet CNC horizontal machining center with FANUC 16-M CNC control, 31.40”x31.40” pallets, travels X-49.10”, Y-39.30”, Z-39.30”, W-360,000 positions in 0.001 degree increments, CAT50 spindle taper, speeds to 6,000 RPM, 25 station ATC, coolant, chip conveyor, 200-220V/3PH/60HZ, s/n: AH800081 (Asset # 20407) (LOCATION – PLANT 4, GRANBY, QC)

- DAEWOO (1998) ACE-H500 twin-pallet CNC horizontal machining center with FANUC 16-M CNC control, 19.75”x19.75” pallets, travels X-31.50”, Y-25.60”, Z-25.60”, W-360,000 positions in 0.001 degree increments, CAT50 spindle taper, speeds to 6,000 RPM, 60-station ATC, coolant, chip conveyor, 200-220V/3PH/60HZ, s/n: AH5X0087 (Asset # 20107)

- DAEWOO ACE-80 twin-pallet CNC horizontal machining center with FANUC SERIES 16-M CNC control, 31.50”x31.50” pallets, travels X-49.30”, Y-39.40”, Z-39.40”, W-360,000 positions in 0.001 degree increments, CAT50 spindle taper, speeds to 4,000 RPM, 90 station ATC, coolant, chip conveyor, 200-220V/3PH/60HZ, s/n: AH800094 (Asset # 20608) (LOCATION – PLANT 4, GRANBY, QC)

CNC TURNING AND LIVE MILLING CENTERS

- MAZAK (2014) MULTIPLEX MP6300-II twin spindle twin turret CNC live milling and turning center with MAZATROL MATRIX CNC control, 16.93” swing, 57.09” maximum distance between spindles, 16.93” maximum machining diameter, 25.60” maximum shaft workpiece machining length, 8.86” maximum chuck workpiece machining length, travels X1/X2-12.20”, Z1/Z2-23.82”, 3.03” maximum bar capacity, 10” hydraulic chucks, chuck speeds to 4,000 RPM, 12-station turrets with live milling, milling spindle speeds to 4,000 RPM, coolant, chip conveyor, s/n: 252195 (Asset # 14125)

- MAZAK (2007) MULTIPLEX MP6250 twin spindle twin turret CNC live milling and turning center with MAZATROL PC FUSION 640T CNC control, 12.6” swing, 46.91” maximum distance between spindles, 12.60” maximum machining diameter, 19.66” maximum shaft workpiece machining length, travels X1/X2-9”, Z1-17.25” Z2-19.37”, 6.37” maximum chuck workpiece machining length, 2.5” maximum bar capacity, 10” hydraulic chucks, chuck speeds to 4,000 RPM, 12-station turrets with live milling, milling spindle speeds to 4,500 RPM, coolant, chip conveyor, s/n: 192982 (Asset # 14120)

CNC TURNING CENTERS

- MORI SEIKI (R&R 2008) SL8 CNC turning center with FANUC SERIES 21i-T CNC control, 39.90” swing over bed, 35.40” max turning diameter, 43.30” max turning length, 10.20” max bar capacity, travels, X-16.50”, Z-43.30”, speeds to 550 RPM, coolant, chip conveyor, 220V/3PH/60HZ, s/n: 293 (Asset # 14408) (LOCATION – PLANT 4, GRANBY, QC)

- DAEWOO (1996) PUMA 10HC CNC turning center with FANUC O-T CNC control, 19.7” swing over bed, 14.6” maximum turning diameter, 20.7” maximum turning length, 2.9” maximum bar capacity, 10” diameter fixture chuck, speeds to 3,500 RPM, travels X-8.3”, Z-21.7”, 10-station ATC, hydraulic programmable tailstock, tool checker arm, coolant, chip conveyor, 220V/3PH/60HZ, s/n: PH100658 (Asset # 14115)

- DAEWOO (1996) PUMA 10HC CNC turning center with FANUC O-T CNC control, 19.7” swing over bed, 14.6” maximum turning diameter, 20.7” maximum turning length, 2.9” maximum bar capacity, 10” diameter fixture chuck, speeds to 3,500 RPM, travels X-8.3”, Z-21.7”, 10-station ATC, hydraulic programmable tailstock, tool checker arm, coolant, chip conveyor, 220V/3PH/60HZ, s/n: PH100542 (Asset # 14116)

- DAEWOO (1993) PUMA 10HC CNC turning center with FANUC O-T CNC control, 19.7” swing over bed, 14.6” maximum turning diameter, 20.7” maximum turning length, 2.9” maximum bar capacity, 10” diameter fixture chuck, speeds to 3,500 RPM, travels X-8.3”, Z-21.7”, 10-station ATC, hydraulic programmable tailstock, tool checker arm, coolant, chip conveyor, 220V/3PH/60HZ, s/n: 880011 (Asset # 14111)

- MAZAK (1990) SLANT TURN 50X1500C CNC chucker with MAZATROL T32-2 CNC control, 31.69” swing, 22.05” maximum turning diameter, 59.06” maximum turning length, 15” hydraulic chuck, travels X-22.64”, Z-62.01”, speeds to 3,000 RPM, 10-station ATC, programmable steady rest, coolant, chip conveyor, mist collector, 240V/3PH/60HZ, s/n: 86989 (Asset # 14207)

- SMT SWEDTURN 12 CNC turning center with retrofit FANUC 21i-TA (updated-2005) CNC control, 22.80” swing over bed, 20” maximum turning diameter, 57.67” maximum turning length, 3.60” maximum bar capacity, speeds to 1,500 RPM, travels X-14.96”, Z-55.11”, 12-station ATC, hydraulic programmable tailstock, coolant, chip conveyor, 220V/3PH/60HZ, s/n: 34/583095/10 (Asset # 14101)

CNC VERTICAL MACHINING CENTERS

- OKUMA (2000) MX-45VAE CNC vertical machining center with OKUMA OSPU100M CNC control, 18.11”x29.92” table, travels X-22.05”, Y-18.11”, Z-17.72”, CAT40 spindle taper, speeds to 7,000 RPM, 20-station ATC, coolant, COMSEP 2000 chip separator system, chip conveyor, 220-480V/3PH/60HZ, s/n: 13032401 (Asset # 19508)

- SUPERMAX (2007) XV-1020A CNC vertical machining center with FANUC MXP-100i CNC control, 44.09”x20.47” table, travels X-40.15”, Y-20.47”, Z-21.25”, CAT40 spindle taper, speeds to 8,000 RPM, 24-station ATC, coolant, chip conveyor, 220V/3PH/50-60HZ, s/n: 105280 (Asset # 19507)

- MAZAK (2000) MTV 515/40N CNC vertical machining center with MAZATROL 640 CNC control, 51”x21.5” table, travels X-41”, Y-20”, Z-22”, CAT50 spindle taper, speeds to 6,000 RPM, 30-station ATC, coolant, chip conveyor, 230-460V/3PH/60HZ, s/n: 151090 (Asset # 19106)

- MAZAK (1997) MTV-515/40N CNC vertical machining center with MAZATROL MPLUS CNC control, 51”x21.5” table, travels X-41”, Y-20”, Z-22”, CAT50 spindle taper, speeds to 6,000 RPM, 30-station ATC, coolant, chip conveyor, 230-460V/3PH/60HZ, s/n: 131048 (Asset # 19702)

CONVENTIONAL MACHINE TOOLS

- TOS SUS63 engine lathe with 28” swing, 85” between centers, 19.5” 3-jaw chuck, speeds to 1,120 RPM, 2.5” spindle bore, IN/MM threading, HEIDENHEIN 2-axis DRO, coolant, steady rest, spare chuck, 600V/3PH/60HZ, s/n: 0450052 (Asset # 11212)

- EUMEGA (2001) MDV4 vertical turret milling machine with 10”x50” table, speeds to 4,200 RPM infinitely variable, ACCURITE DRO, power draw bar, power table, coolant, 575V/3PH/50-60HZ, s/n: 3835 (Asset # 18113)

CMM

- BROWN&SHARPE (2013) ONE 7.7.5 coordinate measuring machine with 27.55”x27.55”x19.68” measuring envelope, TESASTAR-P probe body with TESASTAR-M probe head, PC DMIS CAD 2014 WINDOWS PC based control and data acquisition system, s/n 655 (LOCATED AT 9220 R. ARMOUR MONTREAL)

ALSO:

LARGE SELECTION of CAT 50, CAT 40, BT50, BT40 tool holders; machine tool accessories including milling vises, fixtures and clamping; LISTA type tool cabinets and workbenches, plant support equipment and MUCH MORE!

LATE ADDITIONS INCLUDED IN THE SALE!

Quality brand name machine tools, welding and fabricating equipment, material handling and factory equipment featuring: TRAK CNC vertical turret mill; BLANCHARD No20 rotary surface grinder, CHEVALIER FSG-3A818 hydraulic surface grinder; CINCINNATI MILACRON 2MT tool and cutter grinder; OLIVER drill grinder; MITUTOYO FN905 CMM; (5+) MILLER MIG & TIG welders; (5+) LINCOLN MIG & TIG welders; (10+) LINCOLN, NEDERMAN and CPI portable welding fume extractors; (5) IRCO tilt & rotate welding positioners with capacities from 1,000 to 4,000 lbs; DIVERSITECH down draft sanding tables; PANDJIRIS 30-A6 welding manipulator; MOTOMAN robotic welding cell; SULLAIR 100 HP compressor; CANABLAST (2012) shot blast cabinet with media recovery; SULLAIR 50 HP compressor; (2) SULLAIR refrigerated air dryers; HYSTER XL 18,000 LBS CAP forklift; (2) TOYOTA 5,000 LBS capacity forklifts; (2) NISSAN 5,000 LBS capacity forklifts; (3) CROWN late model electric pallet trucks; SKYJACK SJ-III electric scissor lift; coolant-oil separators; ERIEZ magnetic coolant filtration system; large selection of t-slot tables; machine tool accessories including KURT vises, tombstones and fixtures; bench grinders; floor type drill presses; (10+) ROUSSEAU 5 to 7 drawers tool cabinets with perishable tools & MORE!