SMG Inc.

Complete Hydromat & Screw Machine Shop

Date

Thursday, April 16, 2020

Start Time

10:30 AM EDT

Inspection

BY APPOINTMENT ONLY. Please email info@corpassets.com to set a date and time.

Removal

All assets must be removed BY APPOINTMENT ONLY no later than Tuesday, April 28. Please email info@corpassets.com to arrange a date and time.

Industry

*IMPORTANT NOTE REGARDING THE AUCTION*

We are doing our best to ensure our staff and customers are as safe as possible. If you wish to inspect the assets, we ask that you make an appointment so we may take necessary precautions to maintain health and safety protocols. Please maintain your distance between yourself and others and please DO NOT attend if you are experiencing any symptoms of illness or have been exposed to someone who has, or have travelled outside of Canada in the last month.

If you wish for more information but cannot or do not wish to travel, we would be happy to provide an inspection via video and have someone available to answer any questions you may have. Please contact our office at 416.962.9600 or email info@corpassets.com for more details. (Please allow 24 hrs for a response.)

FEATURING: HYDROMAT (R&R by HYDROMAT 2006) HB 45-16 rotary transfer machine with ALLEN BRADLEY PANELVIEW 600 PLC digital microprocessor control; HYDROMAT HB 45-12 rotary transfer machine with digital microprocessor control; (3) HYDROMAT HW 25-12 rotary transfer machines; ACME GRIDLEY RA6 1 ¼ universal automatic screw machine; ACME GRIDLEY RA6 1 universal automatic screw machine; NEW BRITAIN GRIDLEY 2 1/4 universal automatic screw machine; (8) DAVENPORT ¾” MODEL B universal automatic screw machines; BROWN&SHARPE #2 ULTRAMATIC R/S 1 5/8” four slide universal automatic screw machine; LEBLOND 15x45 DUAL DRIVE tool room engine lathe; BRIDGEPORT SERIES vertical turret milling machine; DOALL 1612-0 16x12 vertical band saw; BRIERLEY ZB50 tool and cutter grinder; AGATHON 150-A tool and cutter grinder; INTERSOURCE 510-3508 automatic chip processing system; BARRETT centrifugal chip separator; Assortment of HYDROMAT spare 30 and 40 SERIES units ,valves, tool heads, repair parts, machining heads, collets, flanges, pulleys, milling heads, slotting heads, threading heads, broaching heads; SELECTION of screw machine attachments including slotting, milling, pick-off, back drilling, thread rolling, straddle milling, cross drilling and threading attachments; QUANTITY of cams, collets, gears, tool holders and repair parts; BOWDEN cabinet type aqueous parts washer; inspection & QC equipment, ROCKWELL hardness tester; assortment of power, pneumatic, hand tools and MORE!

THE EXCLUSIVE RIGGER FOR THIS SALE IS:

Martin Beaulieu

2105, Onésime-Gagnon, Lachine, Québec. H8T 3M7

Tel.: 1.450.565.5644 / 1.800.340.5644

mbeaulieu@extranscargo.com / www.extranscargo.com

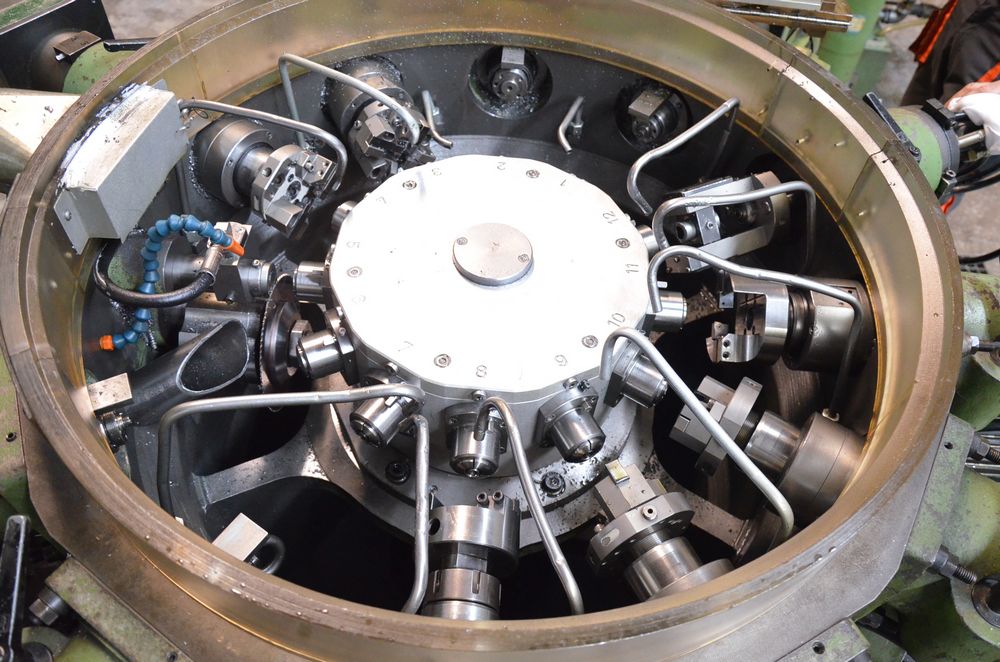

ROTARY TRANSFER MACHINES

- HYDROMAT (R&R by HYDROMAT 2006) HB 45-16 rotary transfer machine with ALLEN BRADLEY PANELVIEW 600 PLC digital microprocessor control, 1.77” max work piece diameter, 4.5” max work piece length capacity, configured as follows: Pos 1: cut off saw, Pos 2: 36-100, Pos 3: 40-80 unit, Pos 4: 30-60 unit, Pos 5: 40-80, Pos 6: 30-60, Pos 7: inverter 40 series, Pos 8: 40-80, Pos 9: 40-80, Pos 10: 40-80, Pos 11: 40-80, Pos 12: 36-100, Pos 13: 30-60, Pos 14: 30-60, Pos 15: 36-100, Pos 16: 30-60 unit, ST100 control valves on all units, high pressure clamping, bar feeder, 480v/3ph/50-60hz, coolant, chip conveyor, work platform, s/n 030381-1

- HYDROMAT HB 45-12 rotary transfer machine with digital microprocessor control, 1.77” max work piece diameter, 6.00” max work piece length capacity, configured as follows: Pos 1: 40 series cut off saw, Pos 2: 20 series vertical with platform, Pos 3: blank, Pos 4: 30 series vertical milling with platform, Pos 5: 30 series milling, Pos 6: 40 series inverter with electronic valve, Pos 7: 30 series open, Pos 8: 40 series turning, Pos 9: 40 series turning, Pos 10: 30 series open, Pos 11: 30 series drill, Pos 12: 30 series drill, high pressure clamping, newer bar feeder, 87hp, 380v/3ph/50-60hz, coolant, chip conveyor, work platform, s/n 210788-51

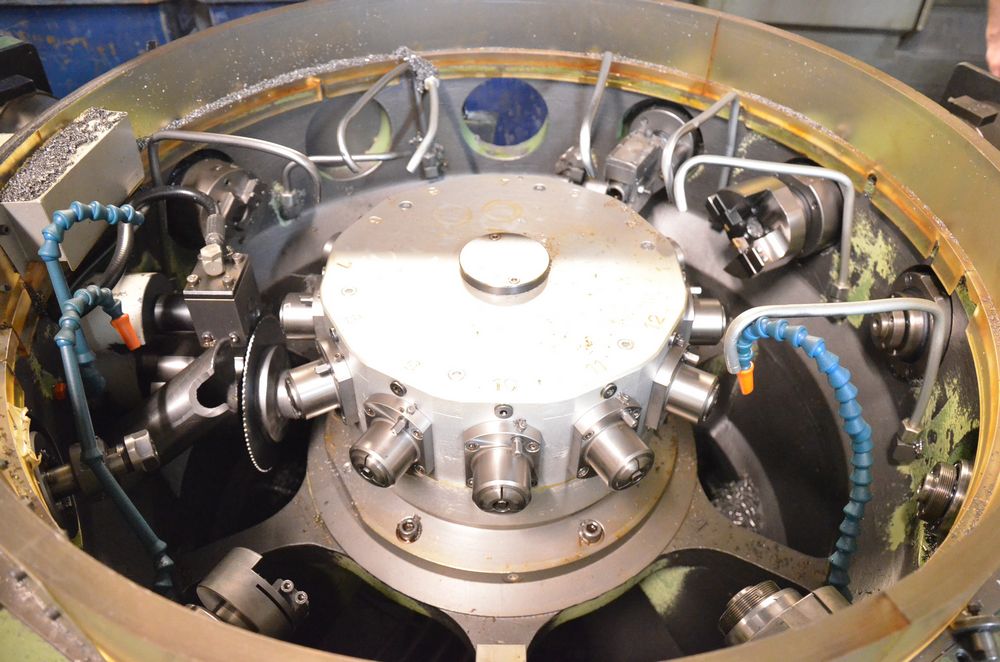

- HYDROMAT HW 25-12 rotary transfer machines with push button pendant control, 1.00” max work piece diameter, 4.00” max work piece length capacity, configured as follows: Pos 1: 20 series quick release cut off saw, Pos 2: 30 Series turning, Pos 3: 30 series turning, Pos 4: 30 series open, Pos 5: 20 series open, Pos 6: 30 series inverter, Pos 7: 30 series turning, Pos 8: 30 series turning, Pos 9: 30 series turning, Pos 10: 30 series turning, Pos 11: 20 series open, Pos 12: 20 series open, high pressure clamping, bar feeder, step loading, coolant, chip conveyor, work platform, 220v/3ph/50-60hz, s/n 150290-380

- HYDROMAT HW 25-12 rotary transfer machines with push button pendant control, 1.00” max work piece diameter, 4.00” max work piece length capacity, configured as follows: Pos 1: 20 series cut off saw, Pos 2: 20 Series vertical with platform, Pos 3: 30 series open, Pos 4: 20 series vertical drilling with platform, Pos 5: 20 series milling, Pos 6: 20 series inverter, Pos 7: 30 series turning, Pos 8: 30 series turning, Pos 9: 20 series drill, Pos 10: 30 series open, Pos 11: 30 series drill, Pos 12: 20 series drill, (3) wired tool breakage detectors, high pressure clamping, bar feeder, step loading, coolant, chip conveyor, work platform, 220v/3ph/50-60hz, s/n 28481-79

- HYDROMAT HW 25-12 rotary transfer machine with push button pendant control, 1.00” max work piece diameter, 4.00” max work piece length capacity, configured as follows: Pos 1: quick release cut off saw, Pos 2: 20 Series turning, Pos 3: blank, Pos 4: blank, Pos 5: 20 series inverter, Pos 6: 30 series turning, Pos 7: 30 series open, Pos 8: 30 series open, Pos 9: 30 series open, Pos 10: 20 series open, Pos 11: 30 series turning, Pos 12: 20 series drill, (4) wired tool breakage detectors, high pressure clamping, bar feeder, step loading, coolant, chip conveyor, work platform, 220v/3ph/50-60hz, s/n 161280-64

SCREW MACHINES

- ACME GRIDLEY RA6 1 ¼ universal automatic screw machine with max 1.25” working diameter, 6.00” max working length, with threading, pneumatic pick-off, back finishing, coolant, chip conveyor, 440v/3ph/50-60hz, s/n 71463

- ACME GRIDLEY RA6 1 universal automatic screw machine with max 1.00” working diameter, 6.00” max working length, coolant, chip conveyor, 440v/3ph/50-60hz, s/n A23966

- NEW BRITAIN GRIDLEY 2 1/4 universal automatic screw machine with max 2.25” working diameter, threading, pick off, coolant, chip conveyor, 440v/3ph/50-60hz, s/n 26442

- (8) DAVENPORT MODEL B universal automatic screw machines with ¾” capacity, 2.25” max working length, tamers, coolant, 440v/3ph/50-60hz, s/n 8161; 3428; 2446; 9406; 10453; 8122; 3781; 3249

- BROWN & SHARPE #2 ULTRAMATIC R/S universal automatic screw machine with 1 5/8” capacity, four slide, coolant, 230v/3ph/50-60hz, s/n 542-2-8554

CONVENTIONAL MACHINE TOOLS

- LEBLOND DUAL DRIVE tool room engine lathe with 15” swing, 45” between centers, speeds to 1800 rpm, 575v/3ph/50-60hz, s/n HC580

- BRIDGEPORT SERIES vertical turret milling machine with 9” x 42” table, speeds to 4200 rpm, power table feed, R8, 575v/3ph/50-60hz, s/n 121230

- DOALL 1612-0 vertical band saw with 16” throat, 12” max work piece height, blade welder and grinder, 220v/3ph/50-60hz, s/n 209-671555

- BRIERLEY ZB50 universal tool and cutter grinder with dual heads, chuck, s/n n/a

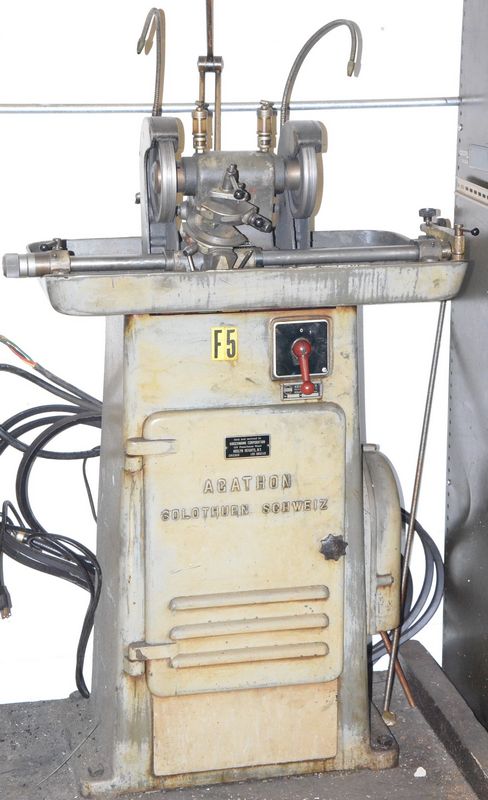

- AGATHON 150-A double end pedestal tool and cutter grinder, s/n 1063-3712

FACTORY SUPPORT EQUIPMENT

- INTERSOURCE 510-3508 automatic chip processing system with chip wringer, auger conveyor, centrifugal separator, controls and integration, s/n 35111D

- BARRETT centrifugal chip separator with gantry hoist load-unload system, s/n n/a

ALSO:

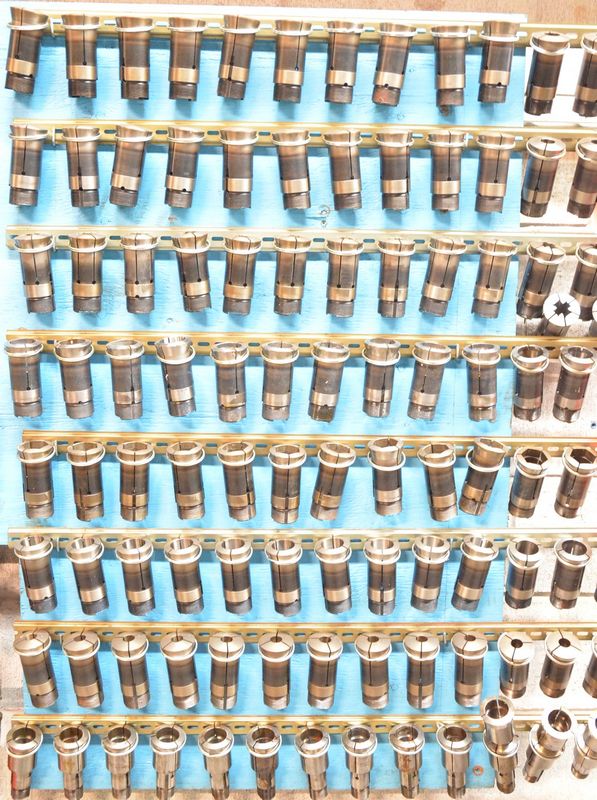

Assortment of HYDROMAT spare 30 and 40 SERIES units ,valves, tool heads, repair parts, machining heads, collets, flanges, pulleys, milling heads, slotting heads, threading heads, broaching heads; SELECTION of screw machine attachments including slotting, milling, pick-off, back drilling, thread rolling, straddle milling, cross drilling and threading attachments; QUANTITY of cams, collets, gears, tool holders and repair parts; BOWDEN cabinet type aqueous parts washer; inspection & QC equipment, ROCKWELL hardness tester; assortment of power, pneumatic, hand tools and MORE!